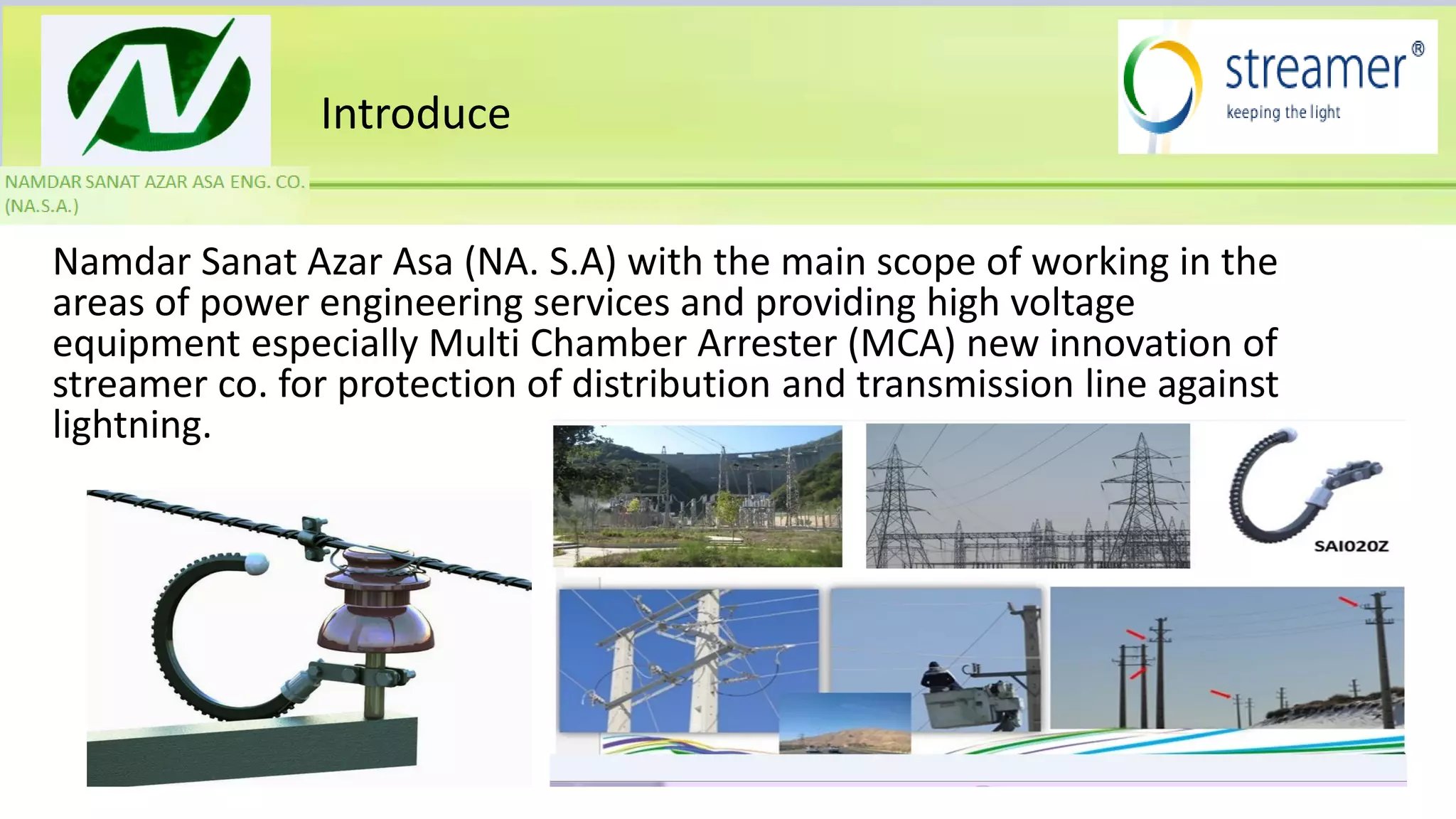

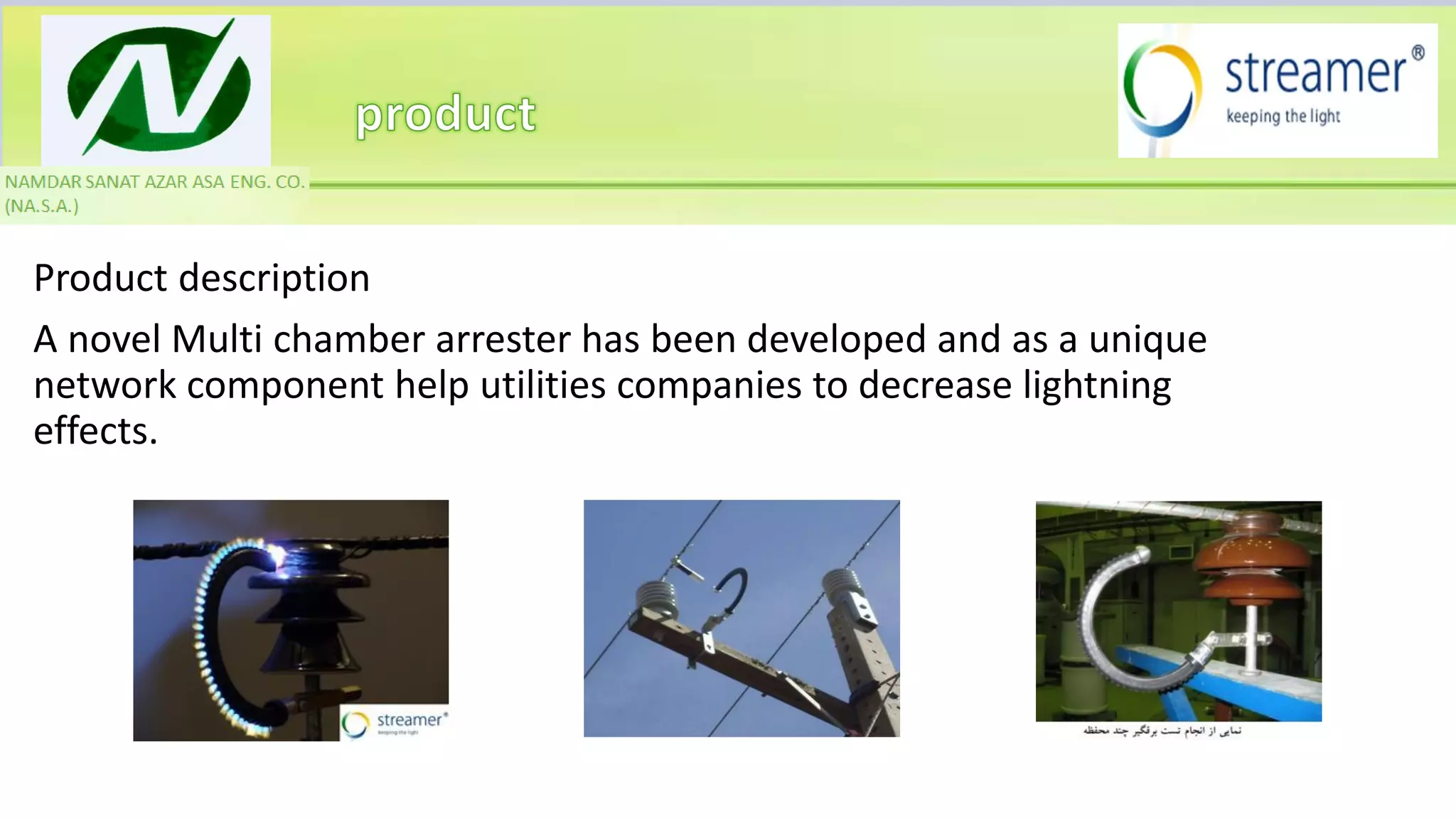

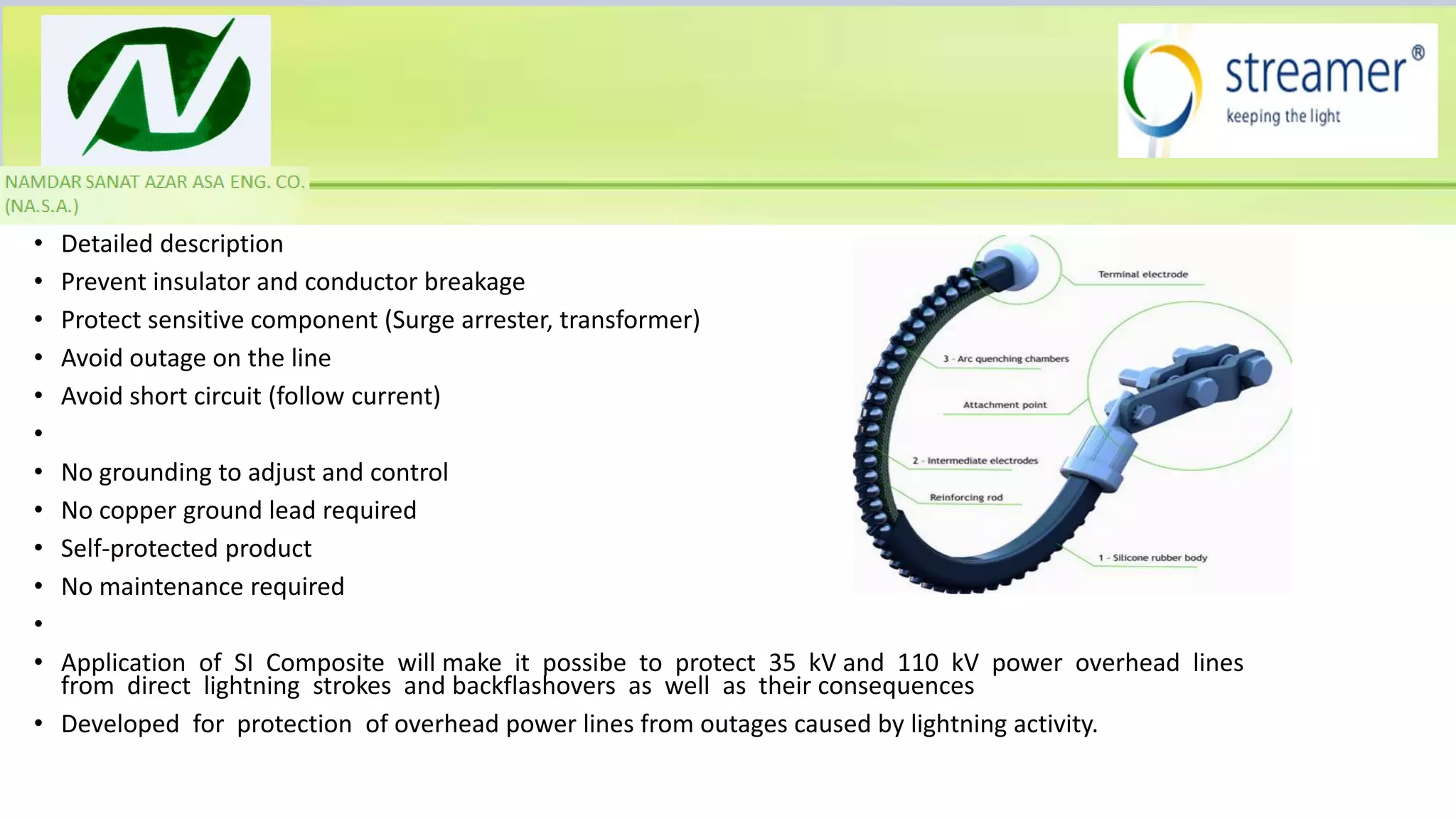

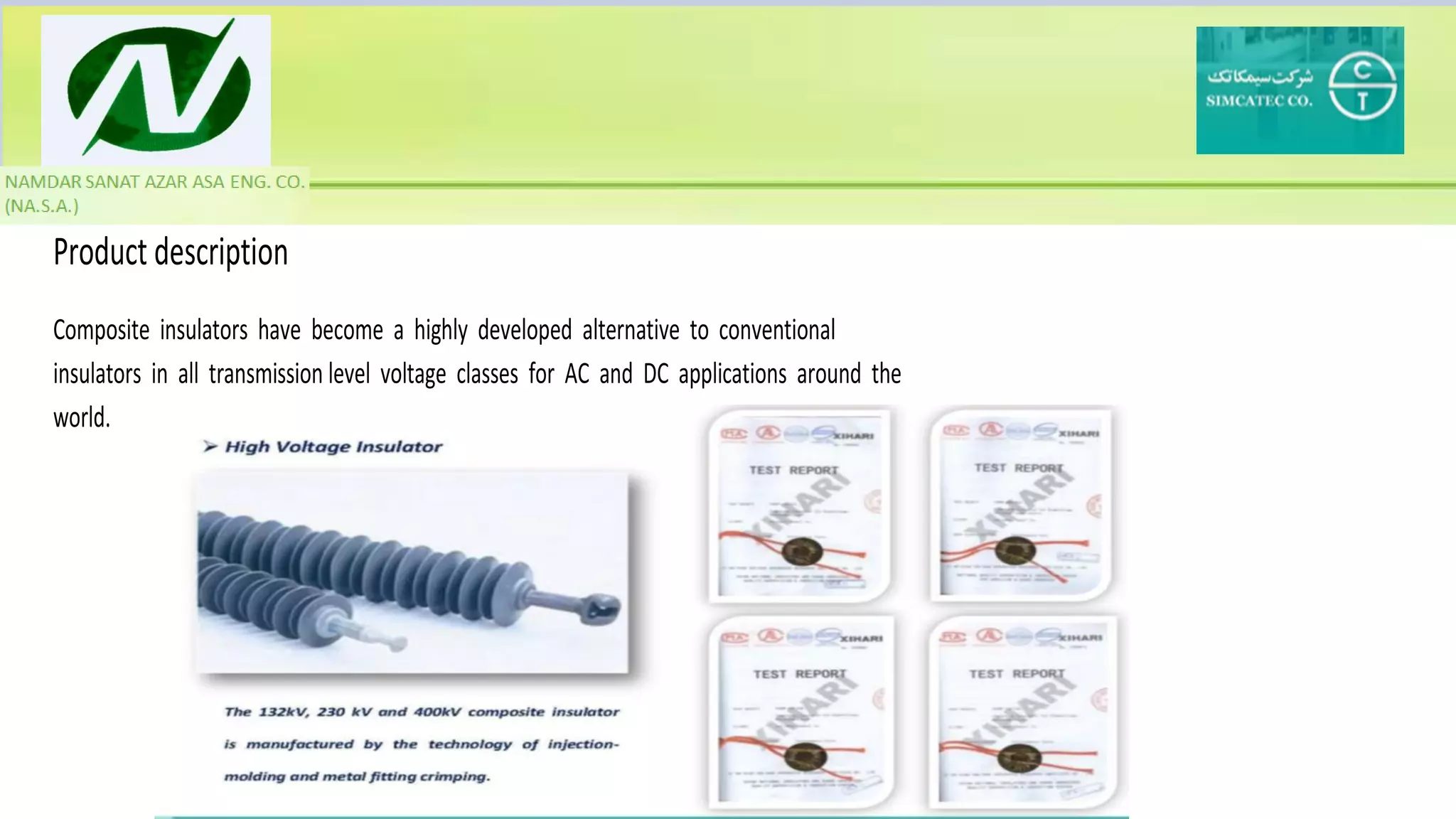

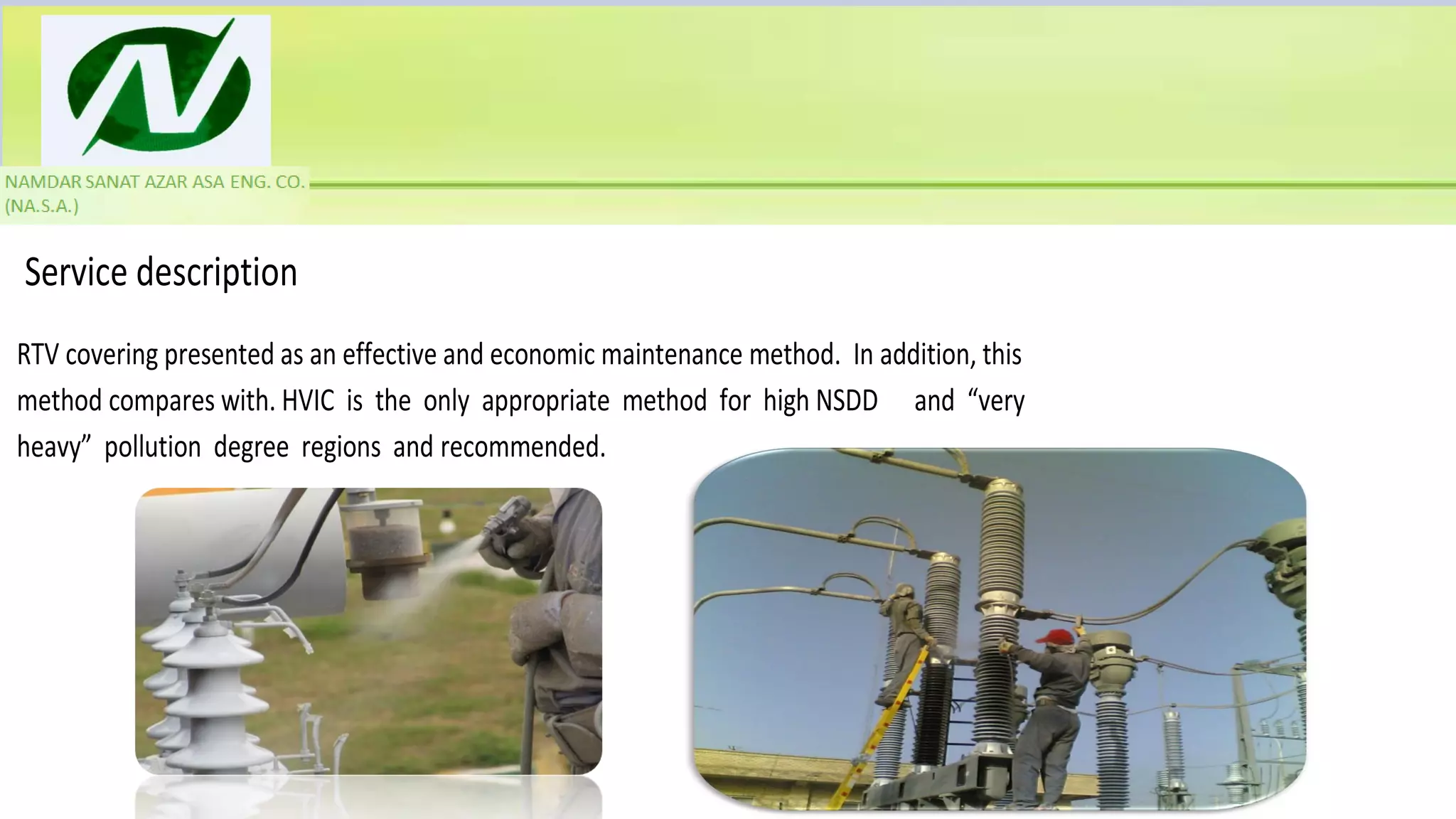

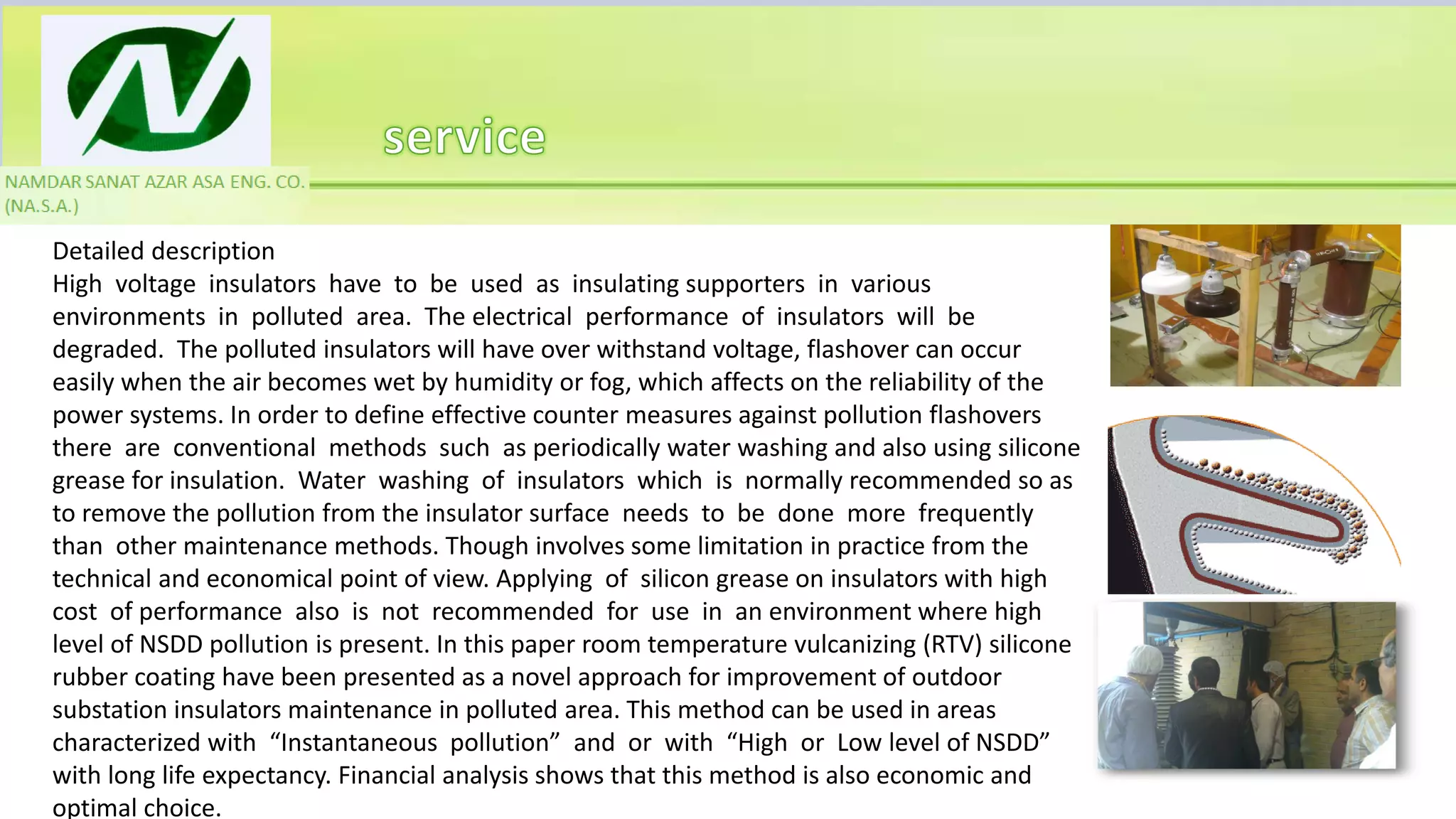

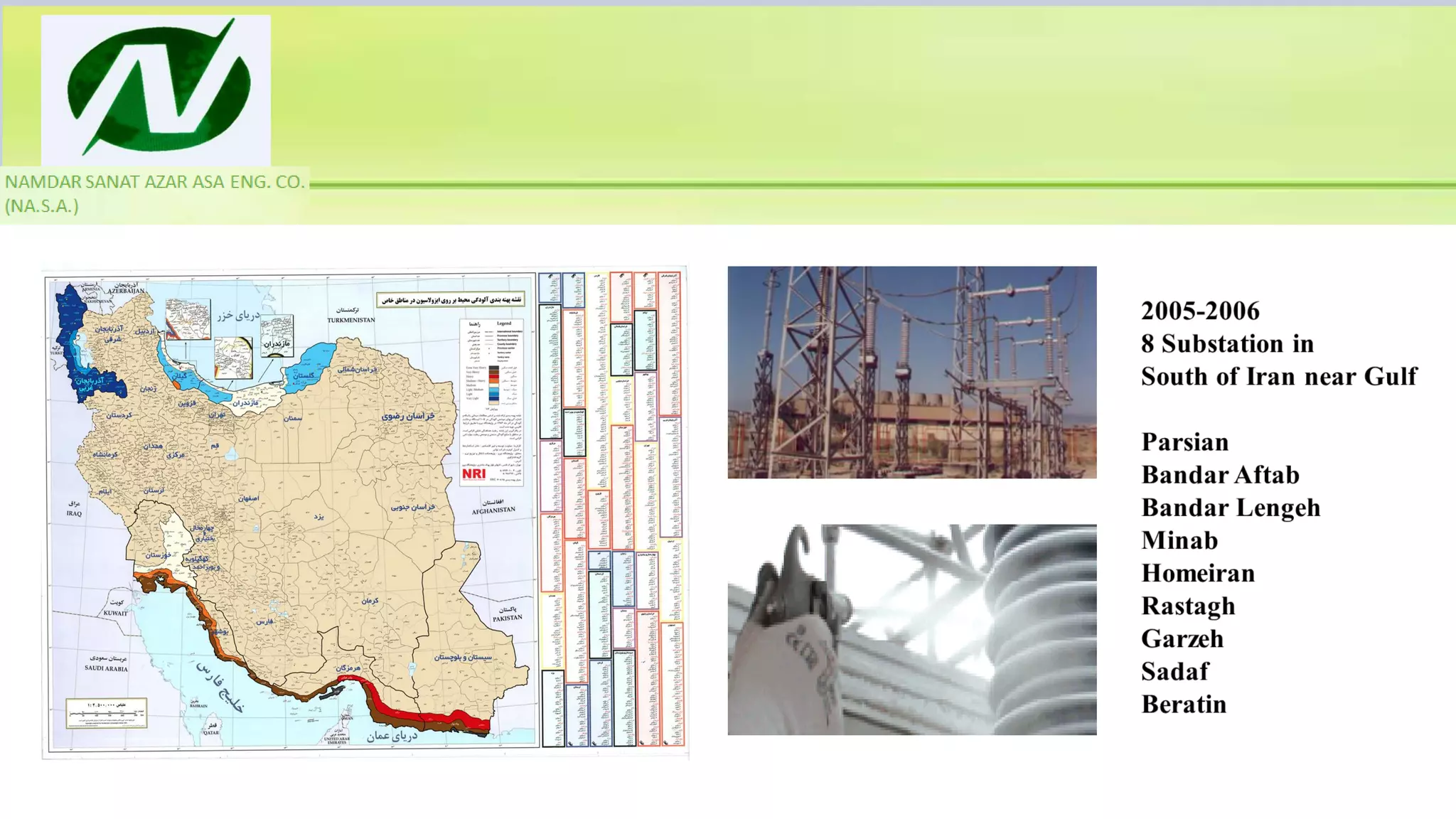

Namdar Sanat Azar Asa (NA. S.A) is an Iranian company that provides power engineering services and high voltage equipment like multi-chamber arresters for protection of distribution and transmission lines against lightning. The company was founded in 1998 by managers and experts from government institutes and private sector to meet needs of Iranian electrical market. It offers products and services for electrical networks up to 400kV, including novel multi-chamber arresters, composite insulators, room temperature vulcanizing silicone rubber coating for insulator maintenance, and transmission line engineering services to improve reliability.