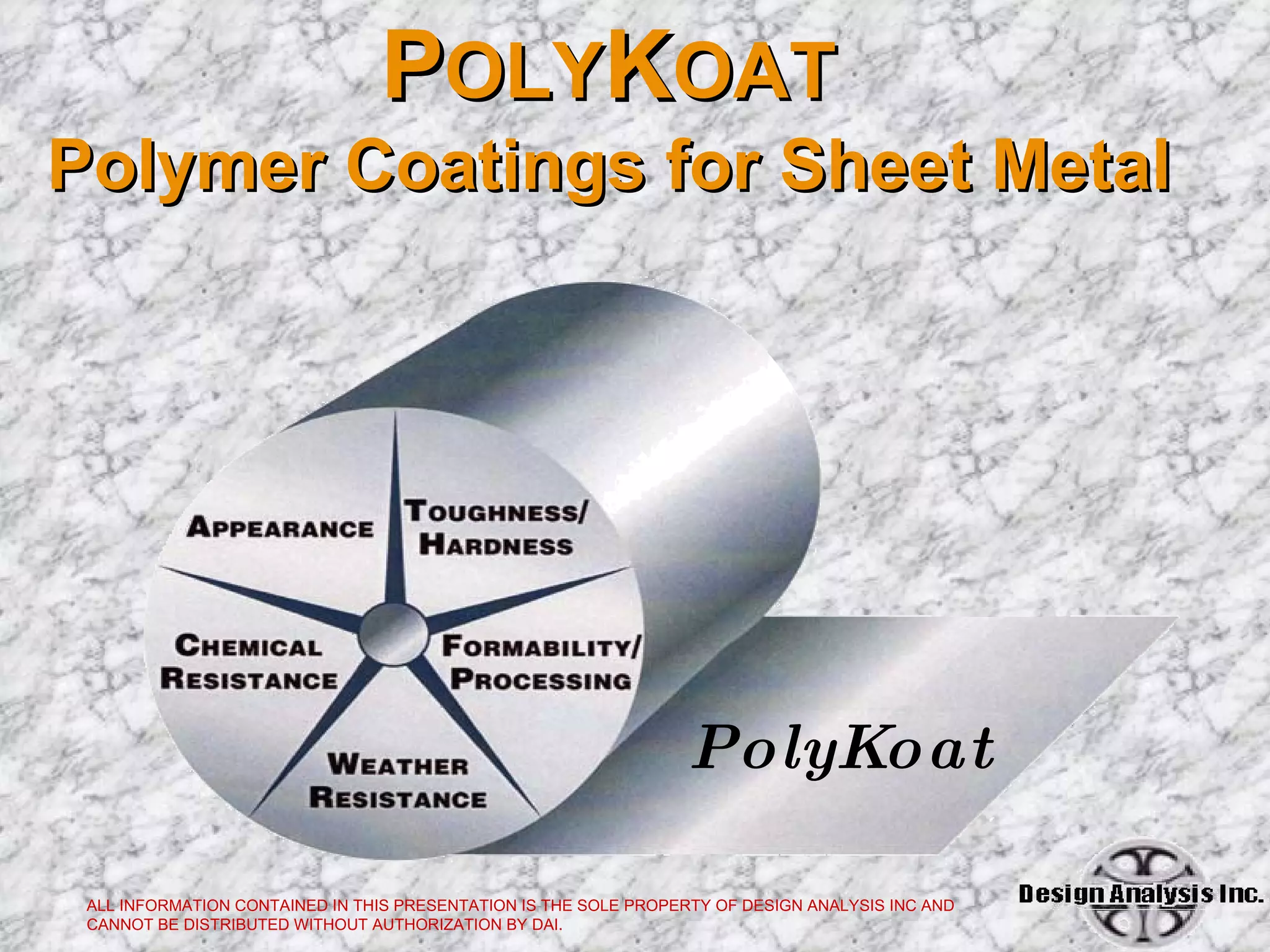

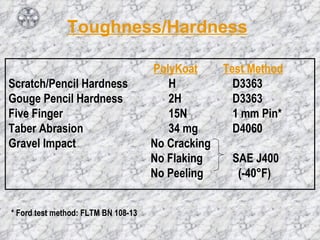

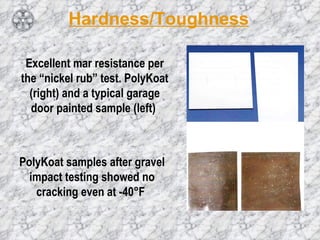

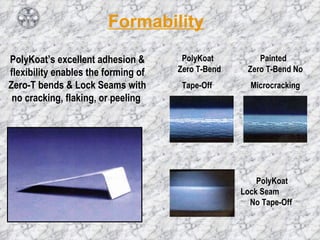

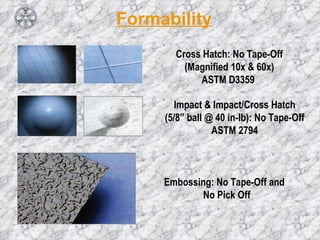

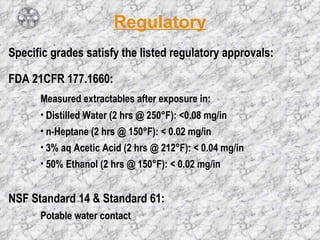

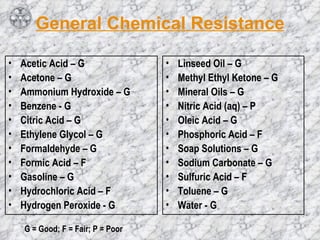

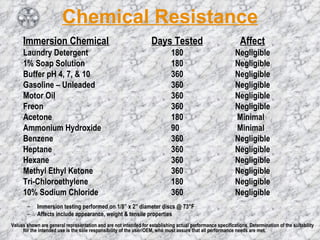

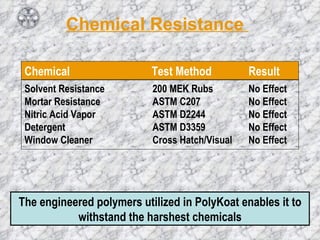

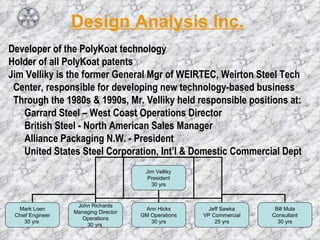

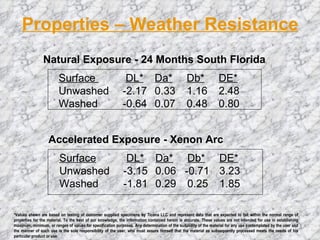

PolyKoat is a polymer coating developed by Design Analysis Inc. for sheet metal. It provides superior abrasion and weather resistance compared to paint or epoxy coatings. PolyKoat coatings are environmentally friendly as they contain no VOCs or BPA. They can be formed into complex shapes without cracking or peeling like painted metals. Extensive testing has shown PolyKoat withstands chemicals, impacts, and long-term outdoor exposure better than traditional coatings.