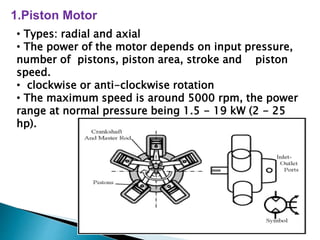

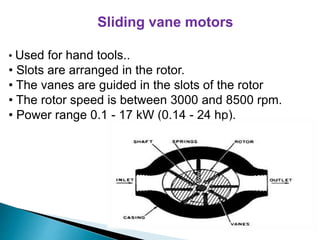

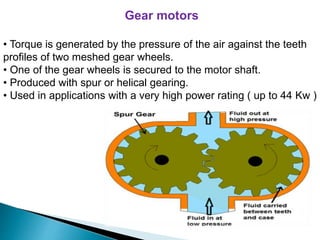

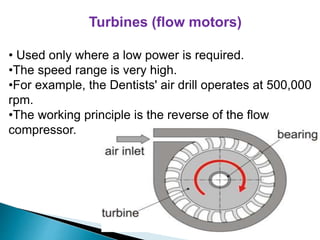

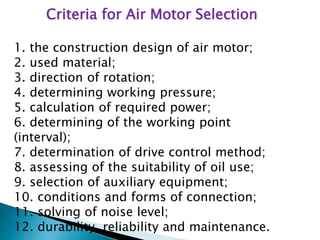

Pneumatic motors have several advantages over electric motors including being more compact, lighter weight, and able to withstand overloads without damage. There are several types of pneumatic motors including piston motors, sliding vane motors, gear motors, and turbines. Piston motors are the most common and can provide power from 1.5-25hp depending on design factors like pressure and piston area. Selection of a pneumatic motor depends on factors such as required power, direction of rotation, pressure, and application.