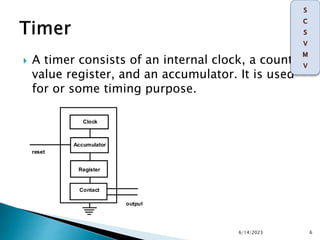

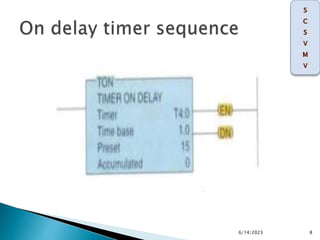

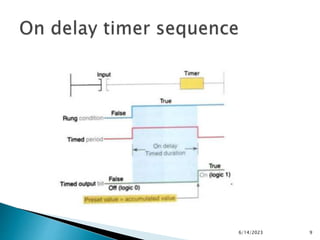

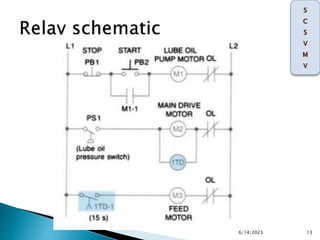

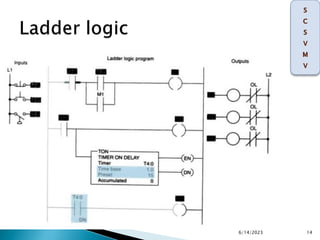

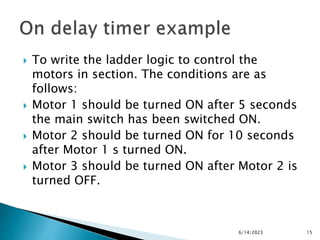

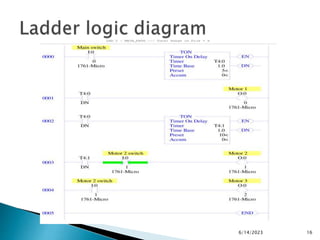

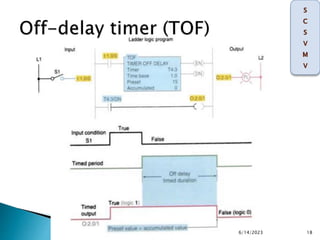

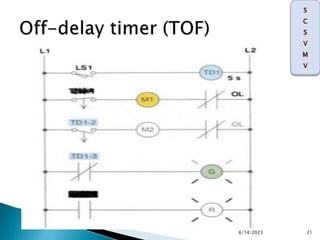

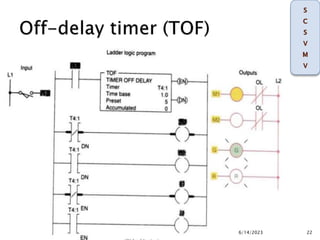

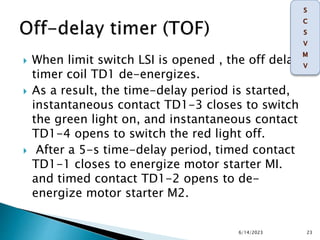

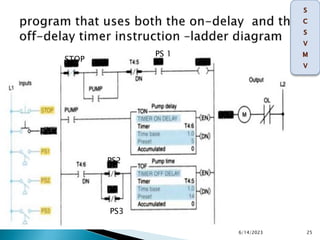

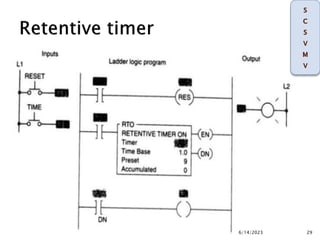

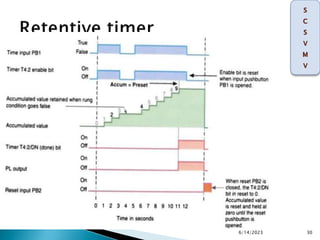

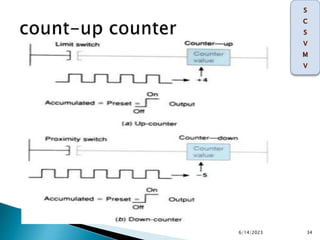

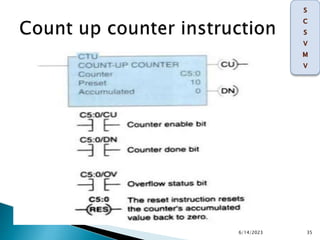

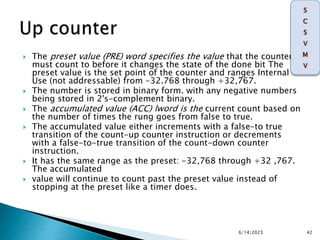

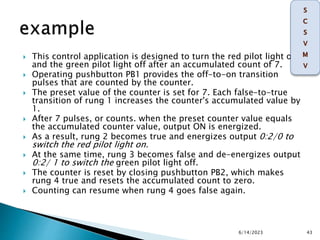

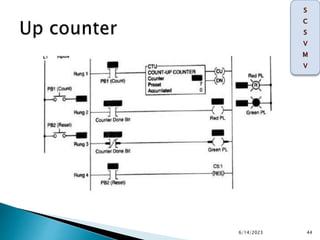

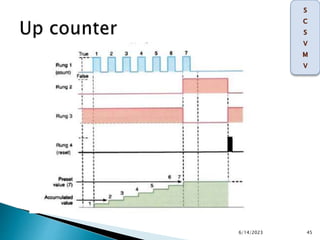

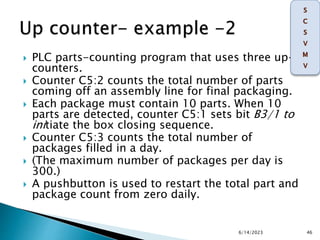

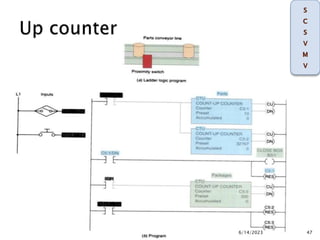

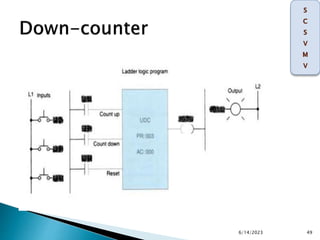

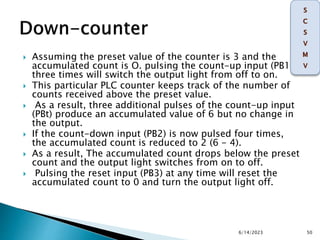

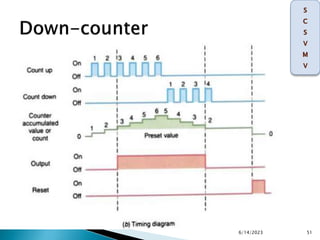

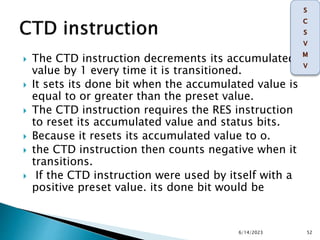

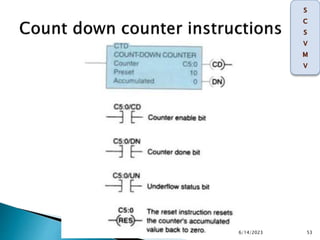

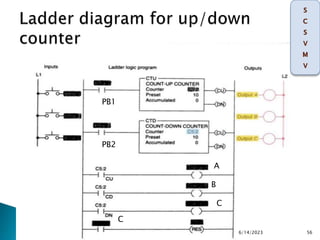

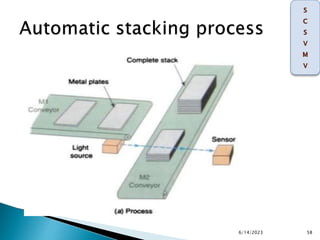

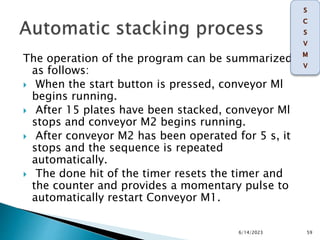

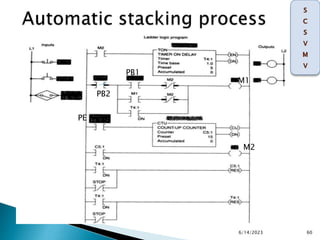

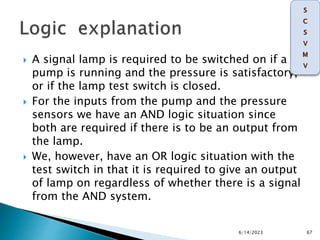

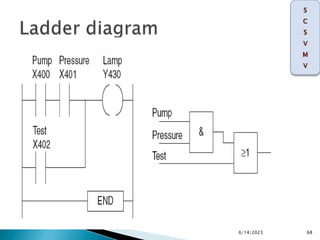

The document discusses various types of timers and counters used in programmable logic controllers (PLCs), including on-delay timers, off-delay timers, retentive timers, up counters, down counters, and accumulator registers. It provides examples of ladder logic diagrams using timers and counters to control sequences of motors and lights. Combining timers and counters allows automation of processes by timing delays between events and counting inputs.