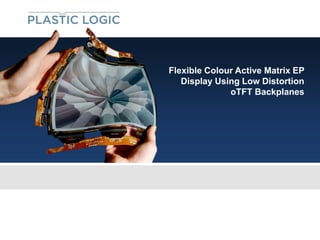

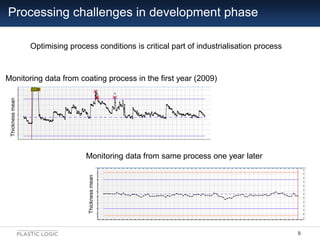

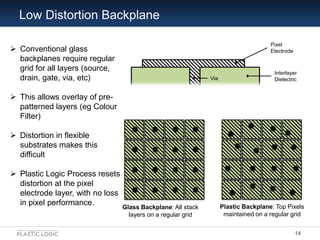

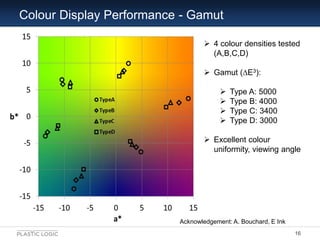

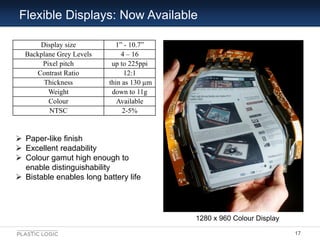

The document discusses the development and manufacturing of flexible color active matrix electronic paper displays using organic thin-film transistors (OTFT) and plastic electronics technology. It highlights the advantages of plastic over traditional materials, such as being lighter, shatterproof, and enabling rapid prototyping and high-volume production. Additionally, it details the unique manufacturing processes and the company's technological advancements that provide a competitive edge in the display market.