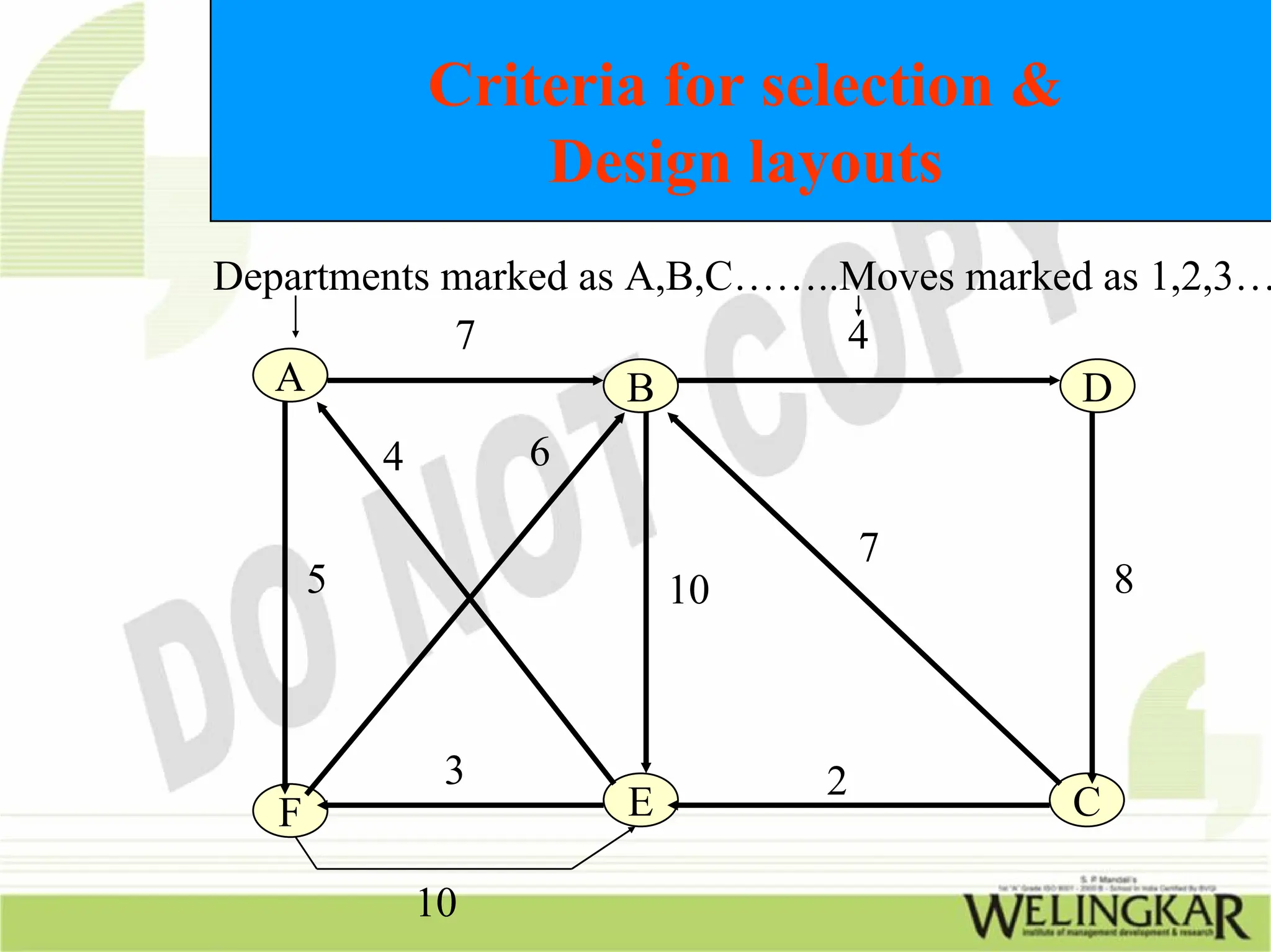

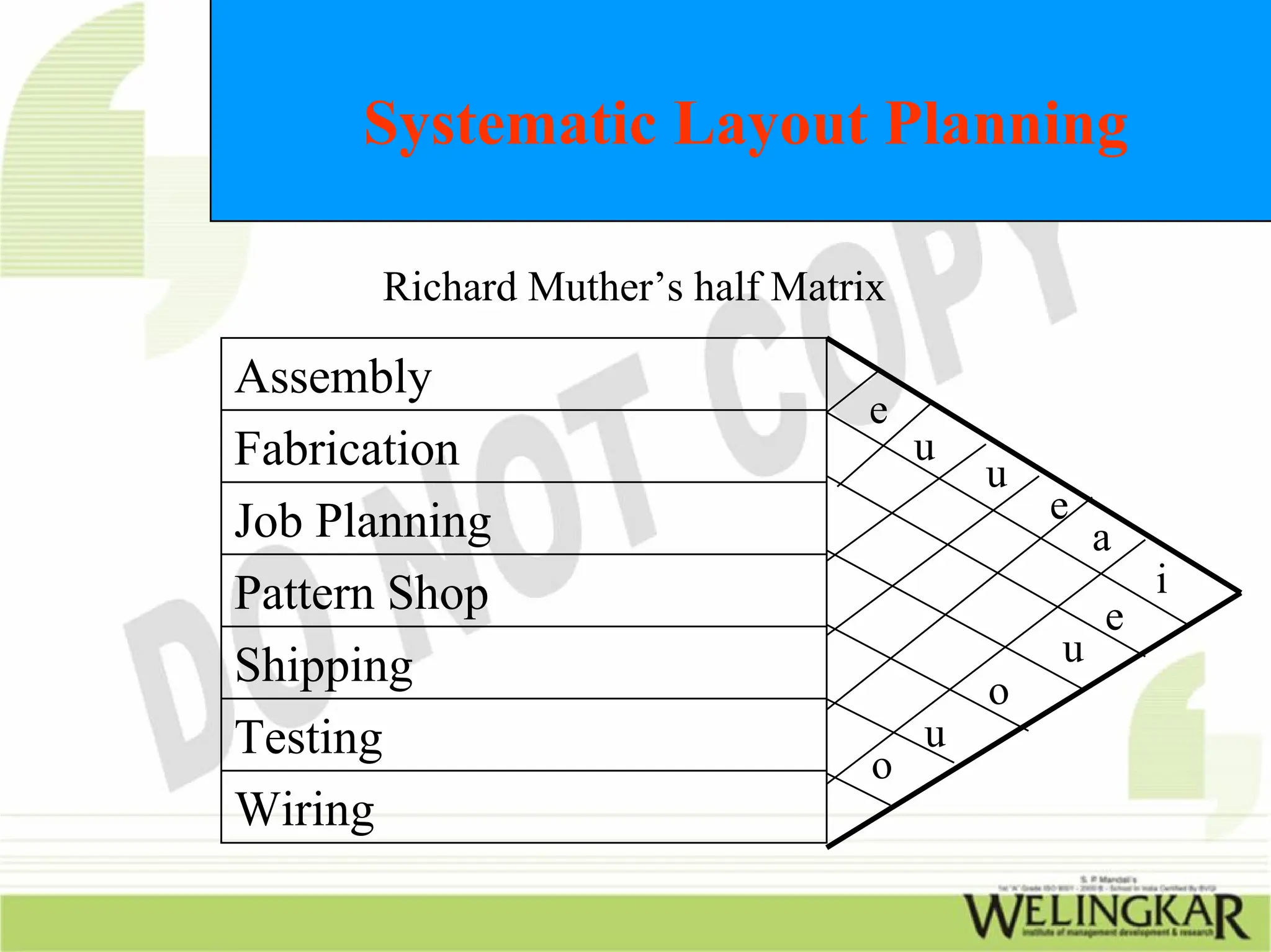

The document discusses plant layout in production operations management, emphasizing the importance of machinery arrangement for efficient production and safety. It outlines the objectives of effective layout design, factors influencing layout decisions, and different types of layouts including process, product, and fixed-position layouts. Additionally, it covers strategies for improving safety and efficiency, methods for planning and optimizing layouts, and the significance of minimizing material handling costs.