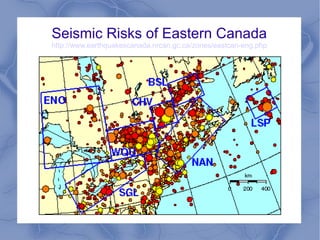

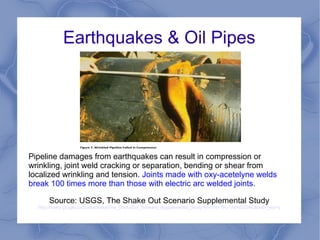

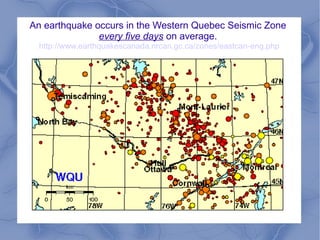

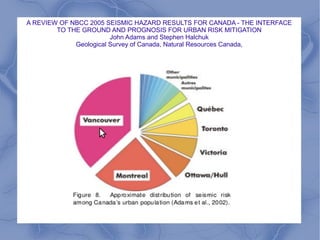

1) Pipelines face risks from earthquakes, including damage to welds from ground movement. Proper design criteria are needed to mitigate seismic risks, especially regarding welds.

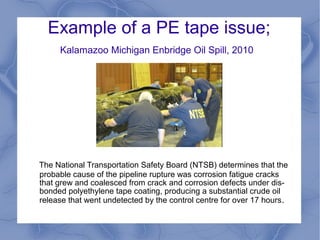

2) Certain bacteria that eat plastic, like Spingomonas and Pseudomonas, may contribute to corrosion under disbonded polyethylene tape coatings on pipelines. More data is needed to understand this risk and potential mitigation measures.

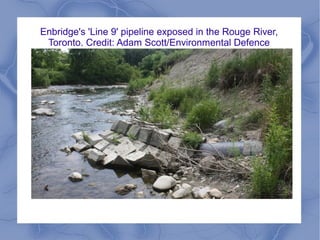

3) Climate change is expected to increase risks to pipelines from more frequent and intense heat waves and rainfall. Proper consideration of these changes is important for safety.