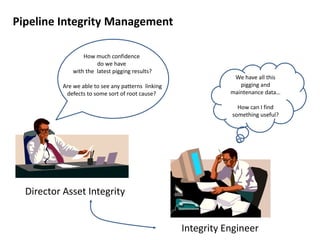

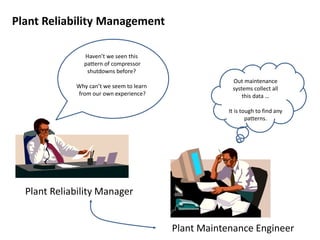

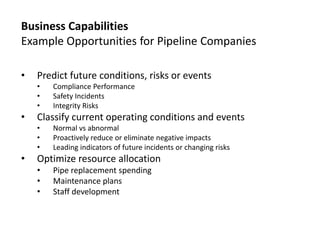

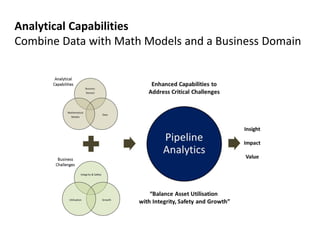

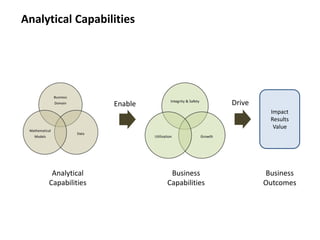

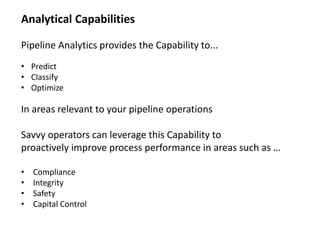

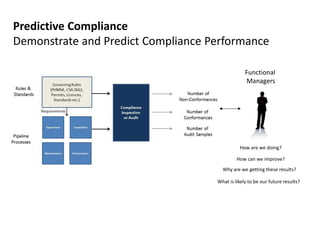

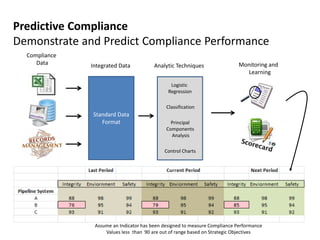

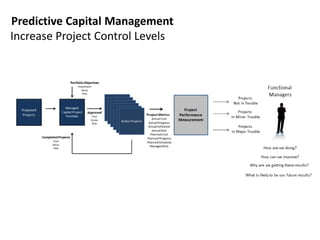

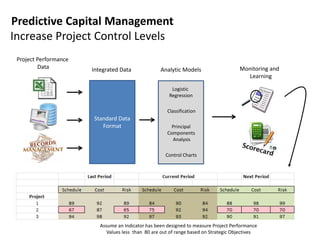

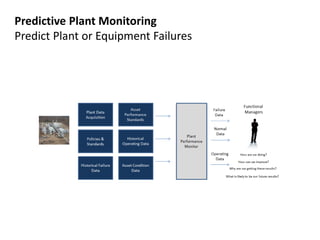

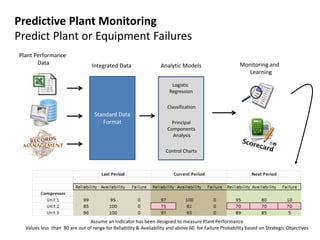

This document introduces pipeline analytics capabilities that can help improve operational performance for oil and gas pipeline companies. It discusses opportunities in regulatory compliance, safety management, pipeline integrity management, and plant reliability management. Required business capabilities include learning from operating experience to anticipate conditions, identify unusual situations, and drive improved results. Necessary analytical capabilities combine data with models in areas like prediction, classification, and optimization to impact compliance, integrity, safety, and capital control. Examples show how predictive analytics could demonstrate and predict compliance performance, increase project control, and predict plant or equipment failures. Feedback is requested from pipeline professionals to refine these ideas.