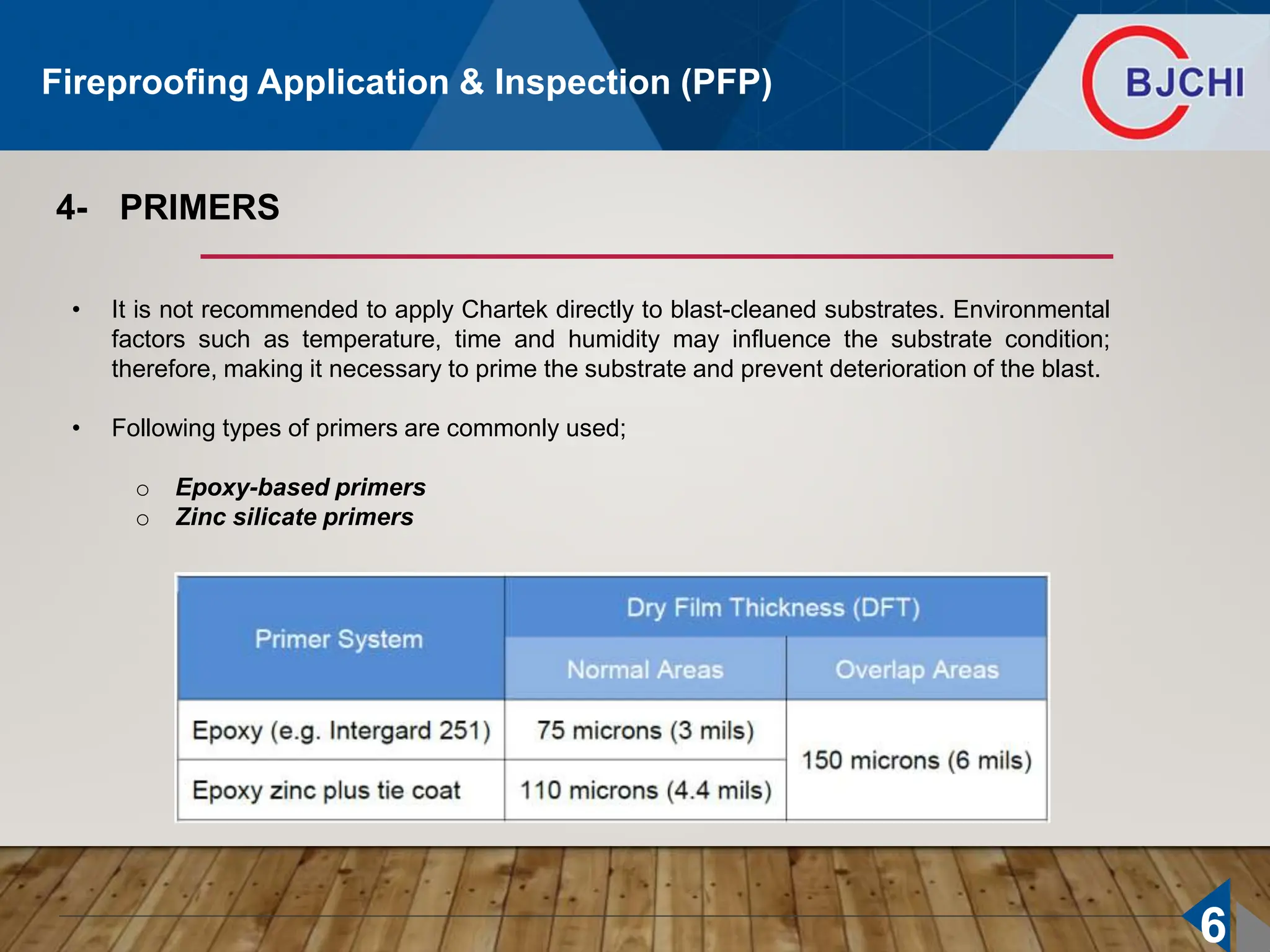

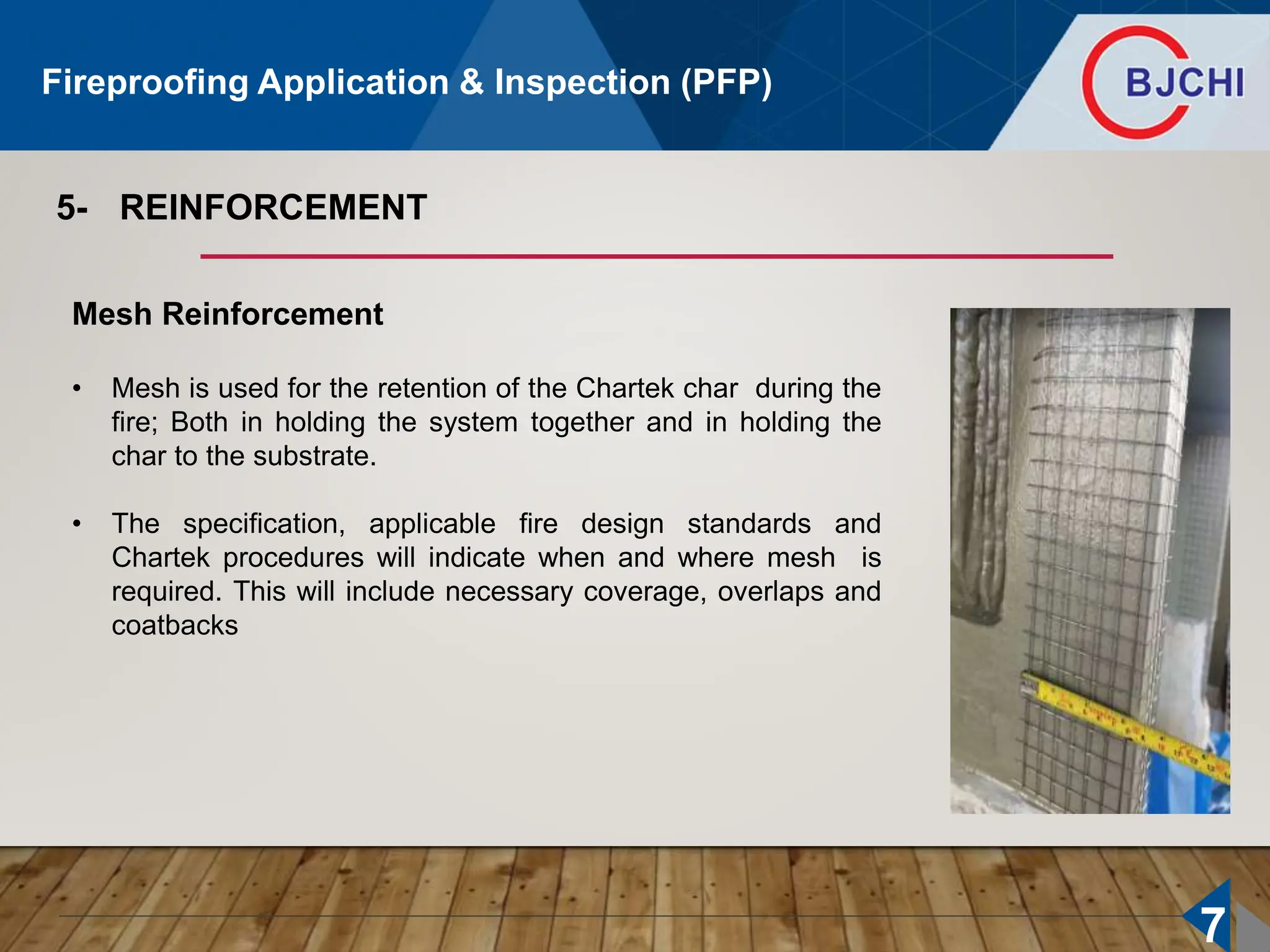

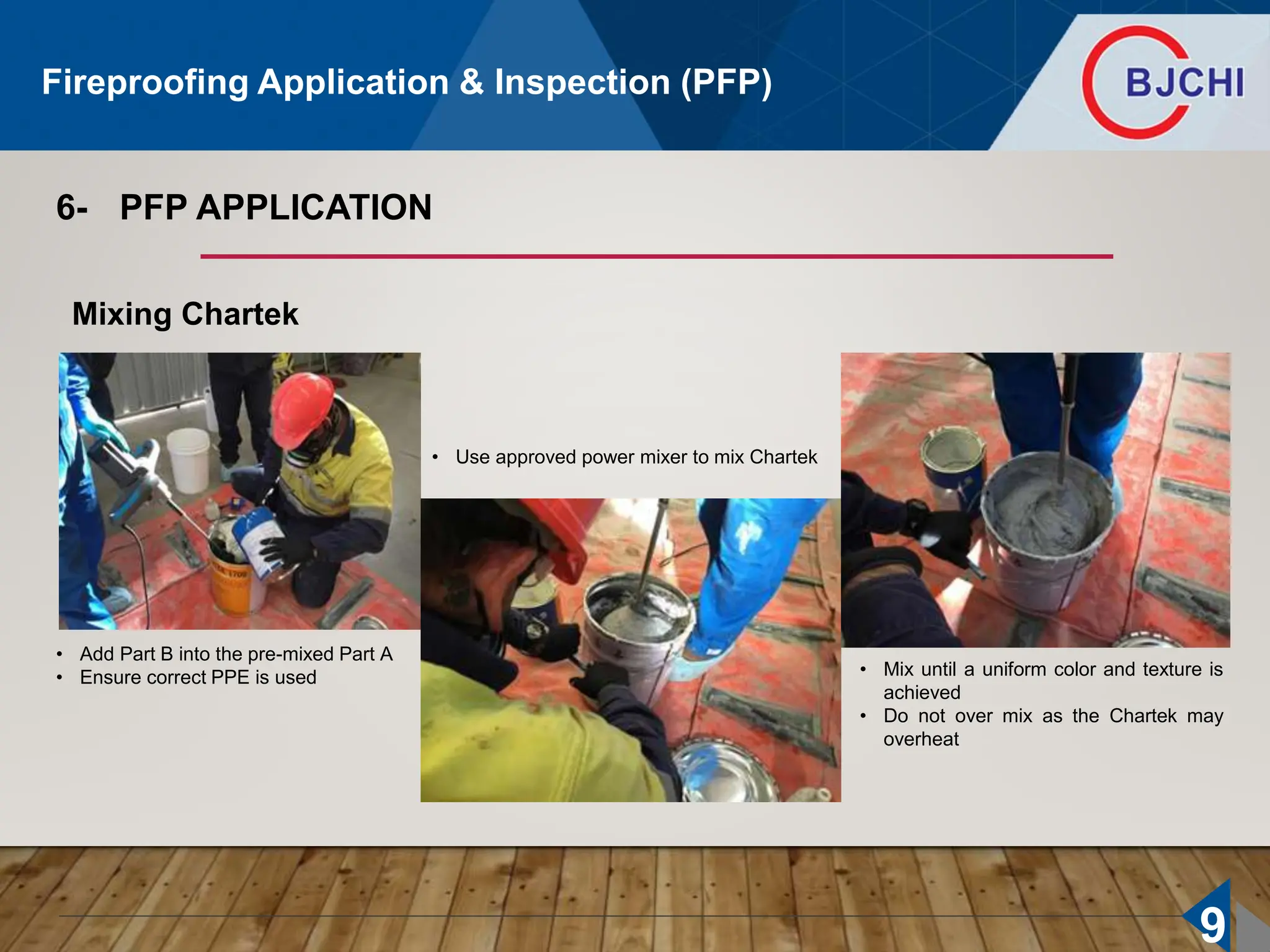

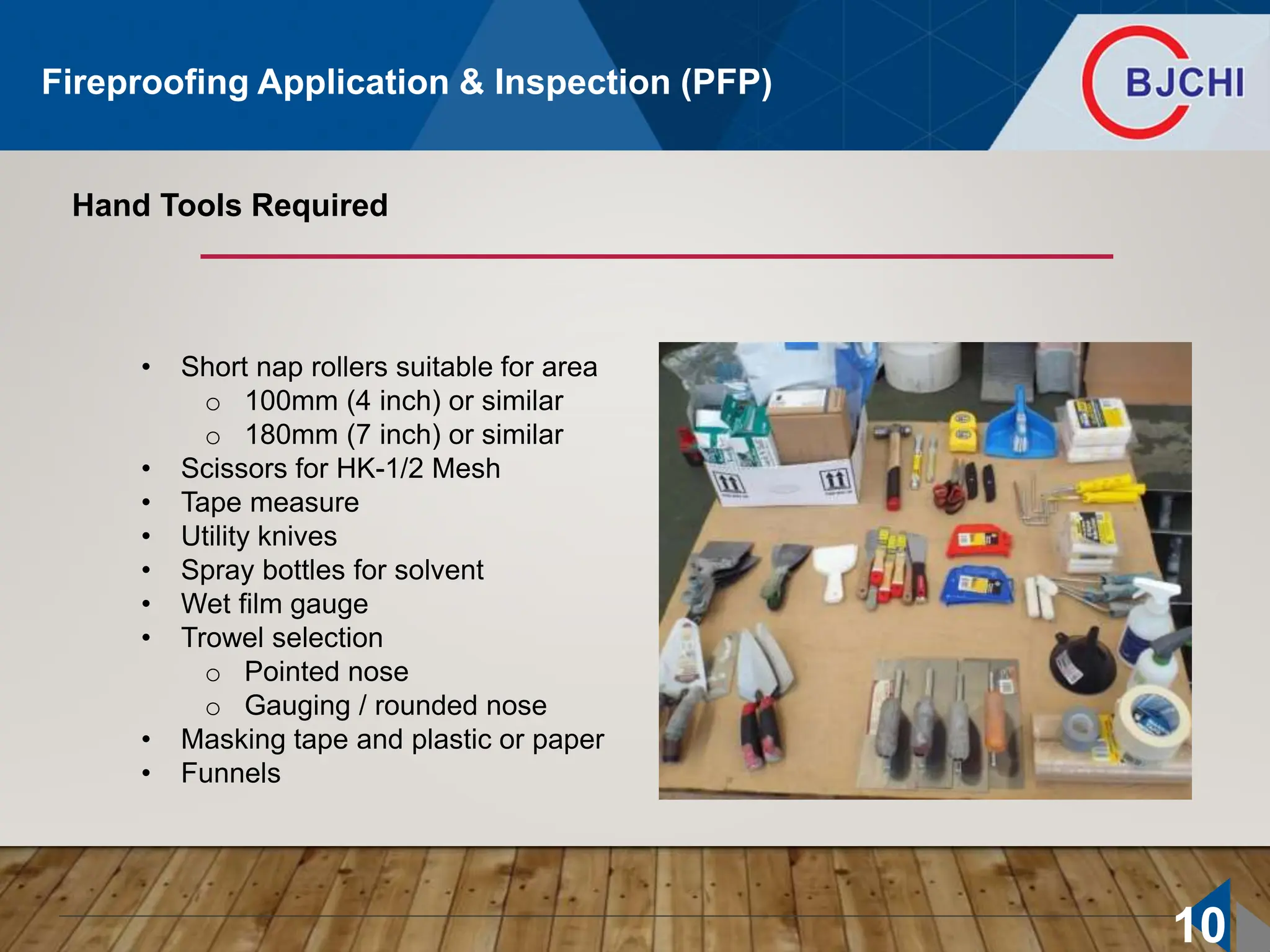

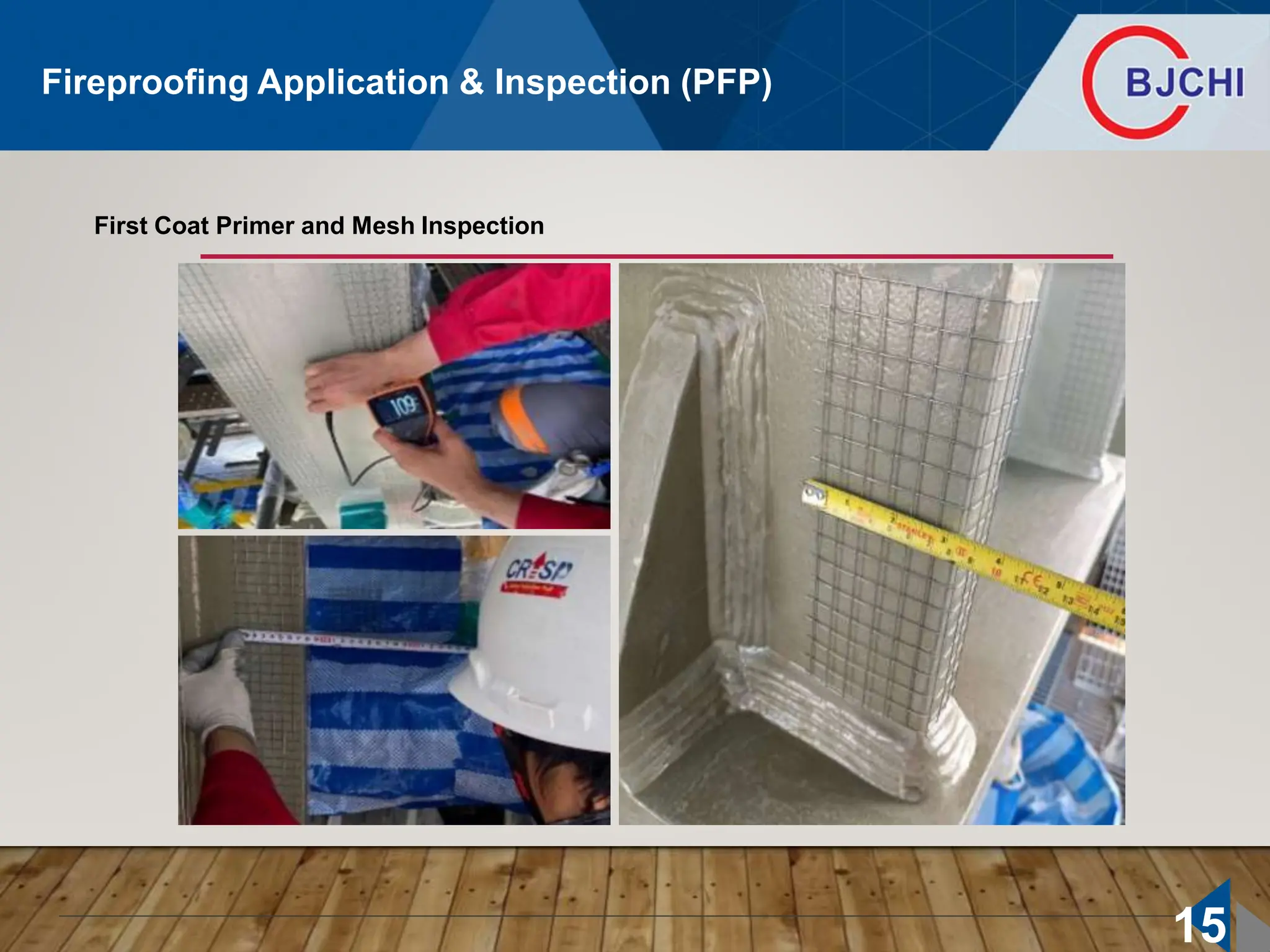

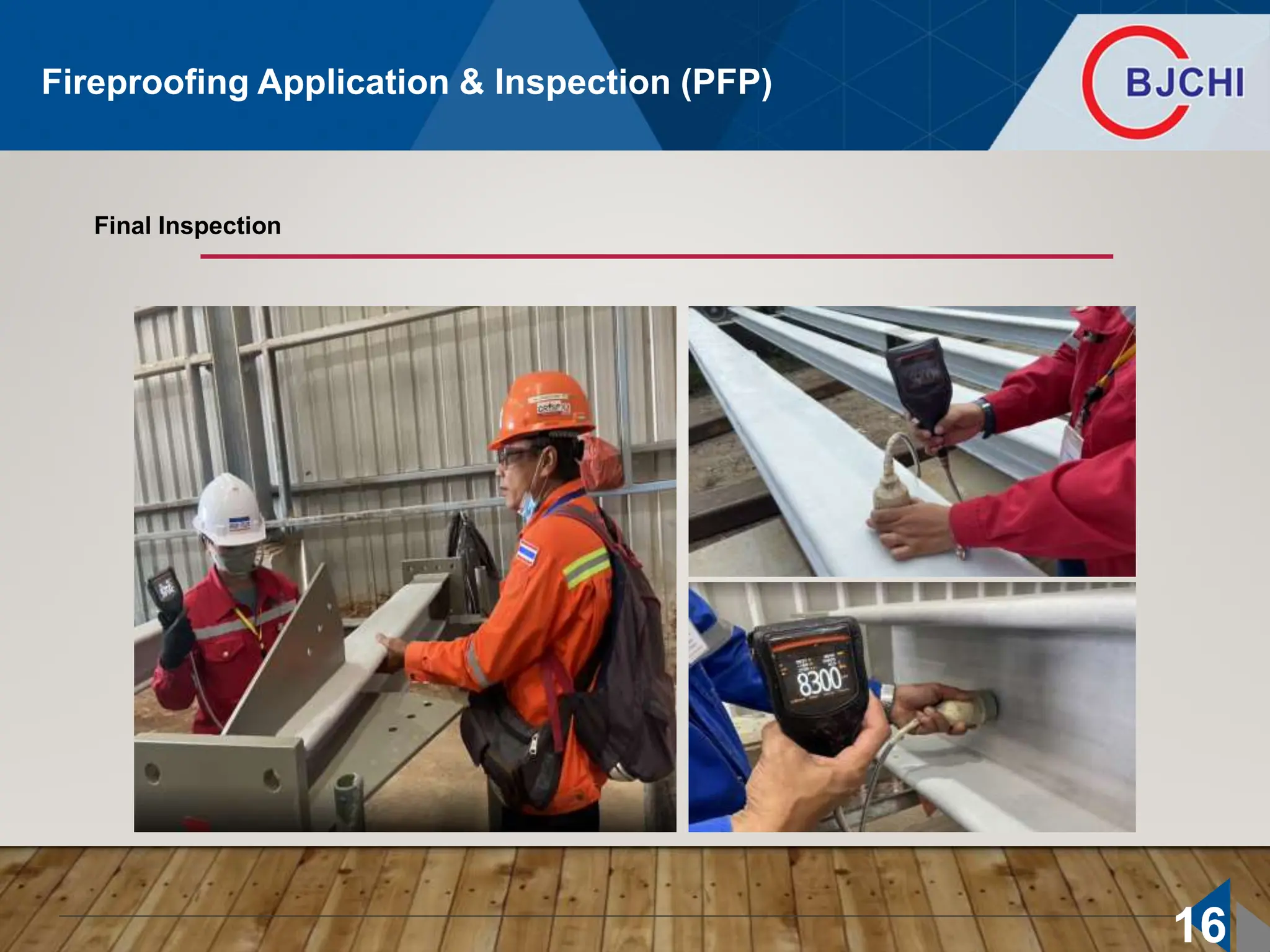

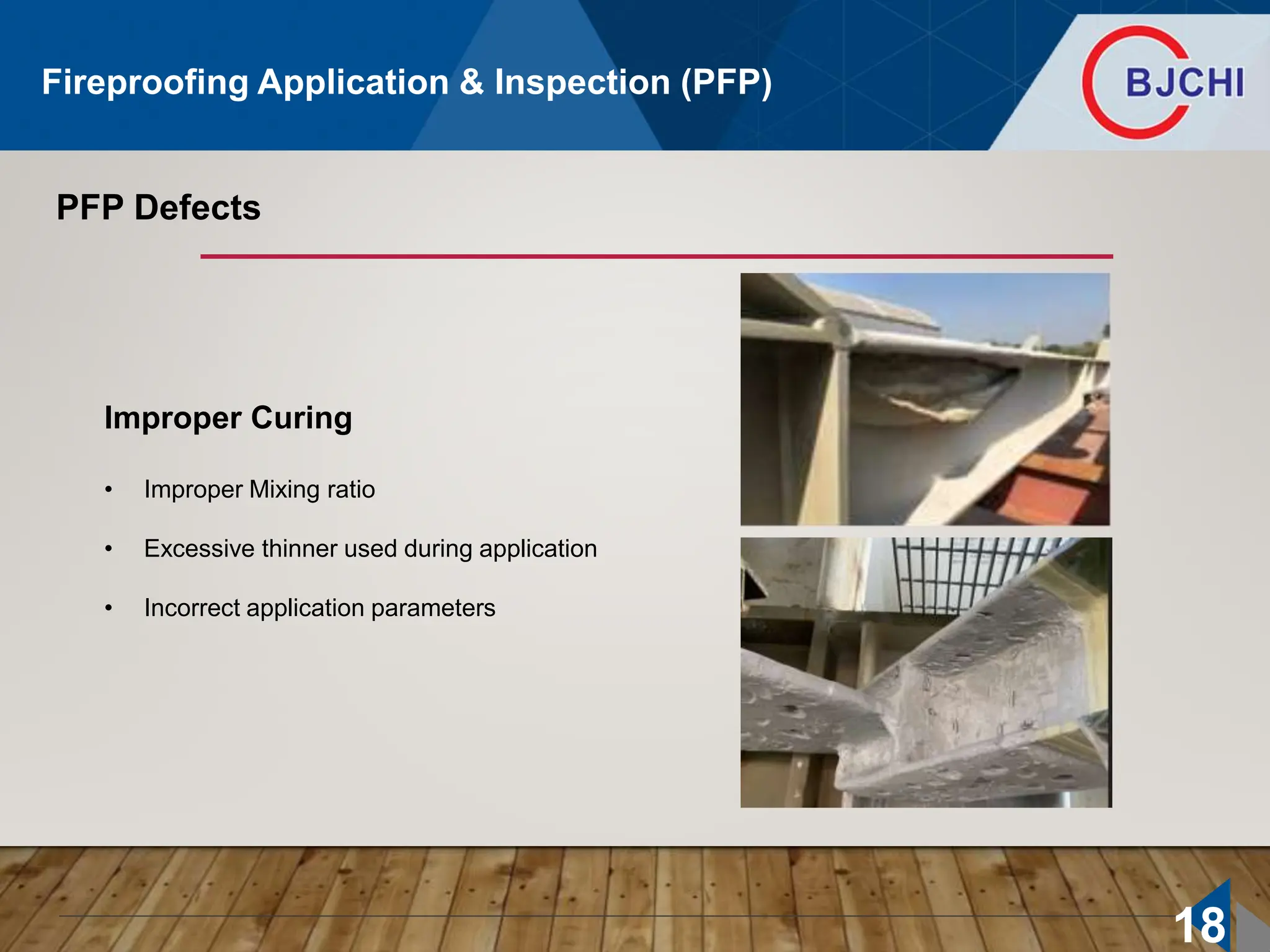

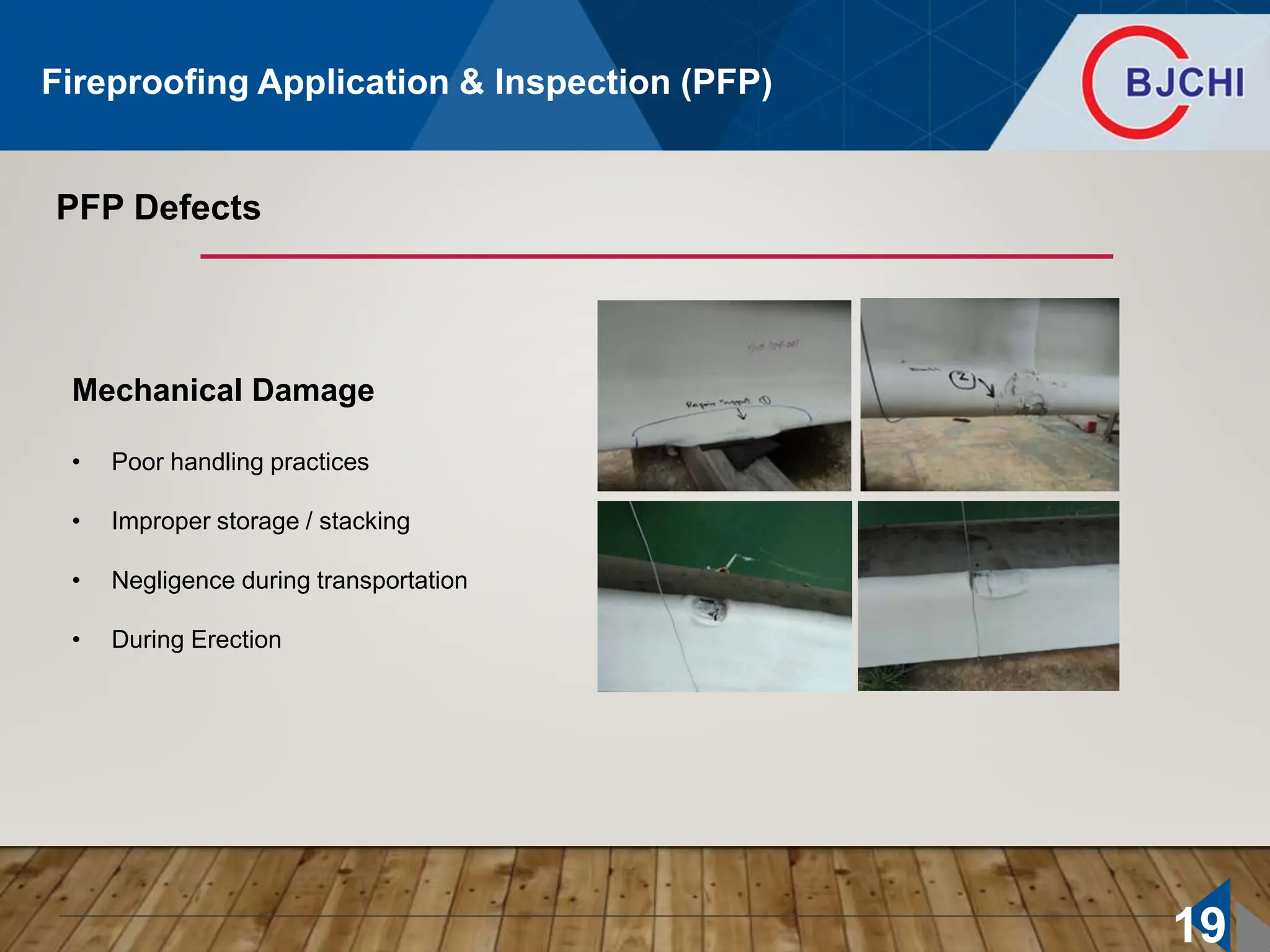

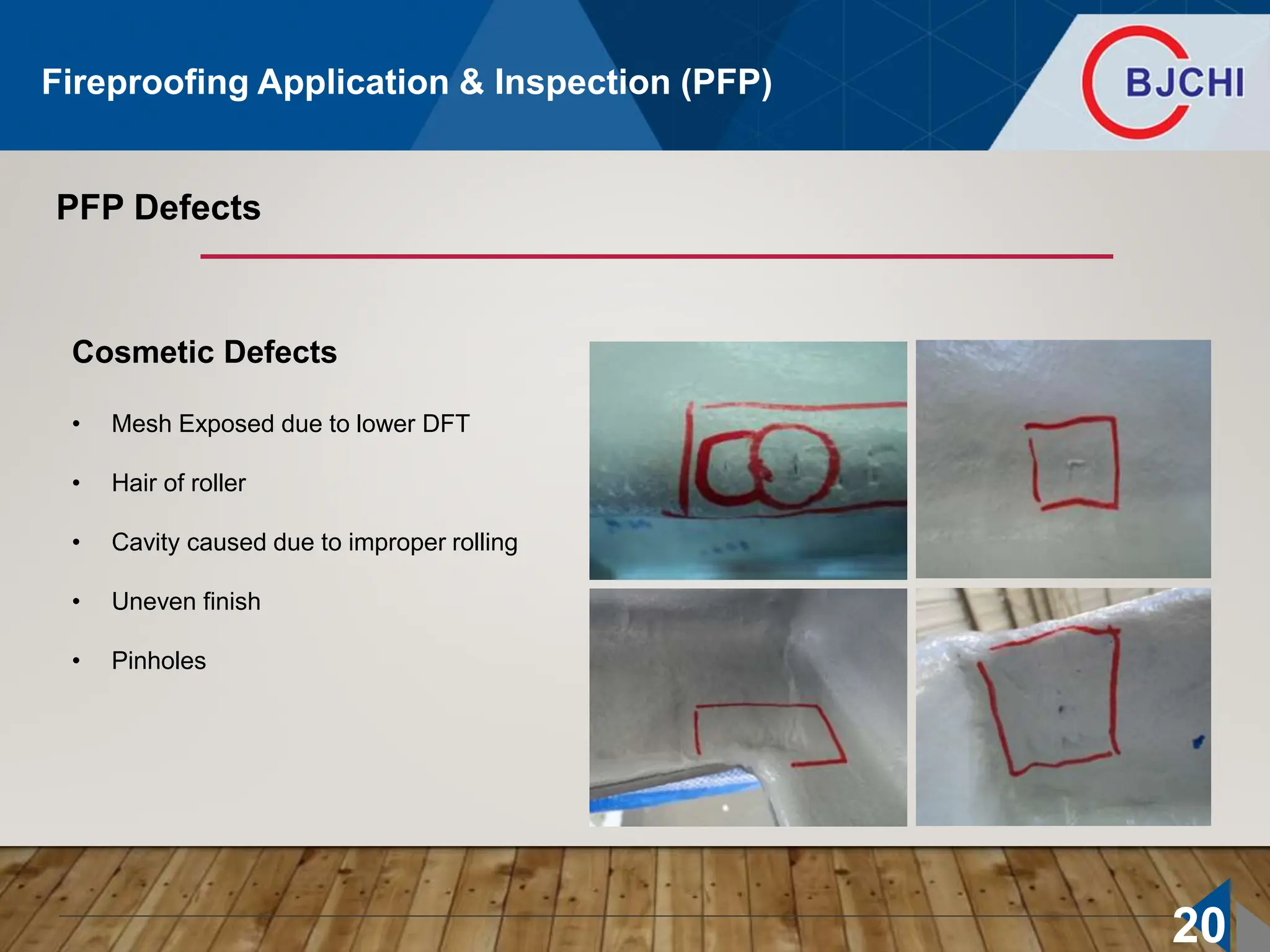

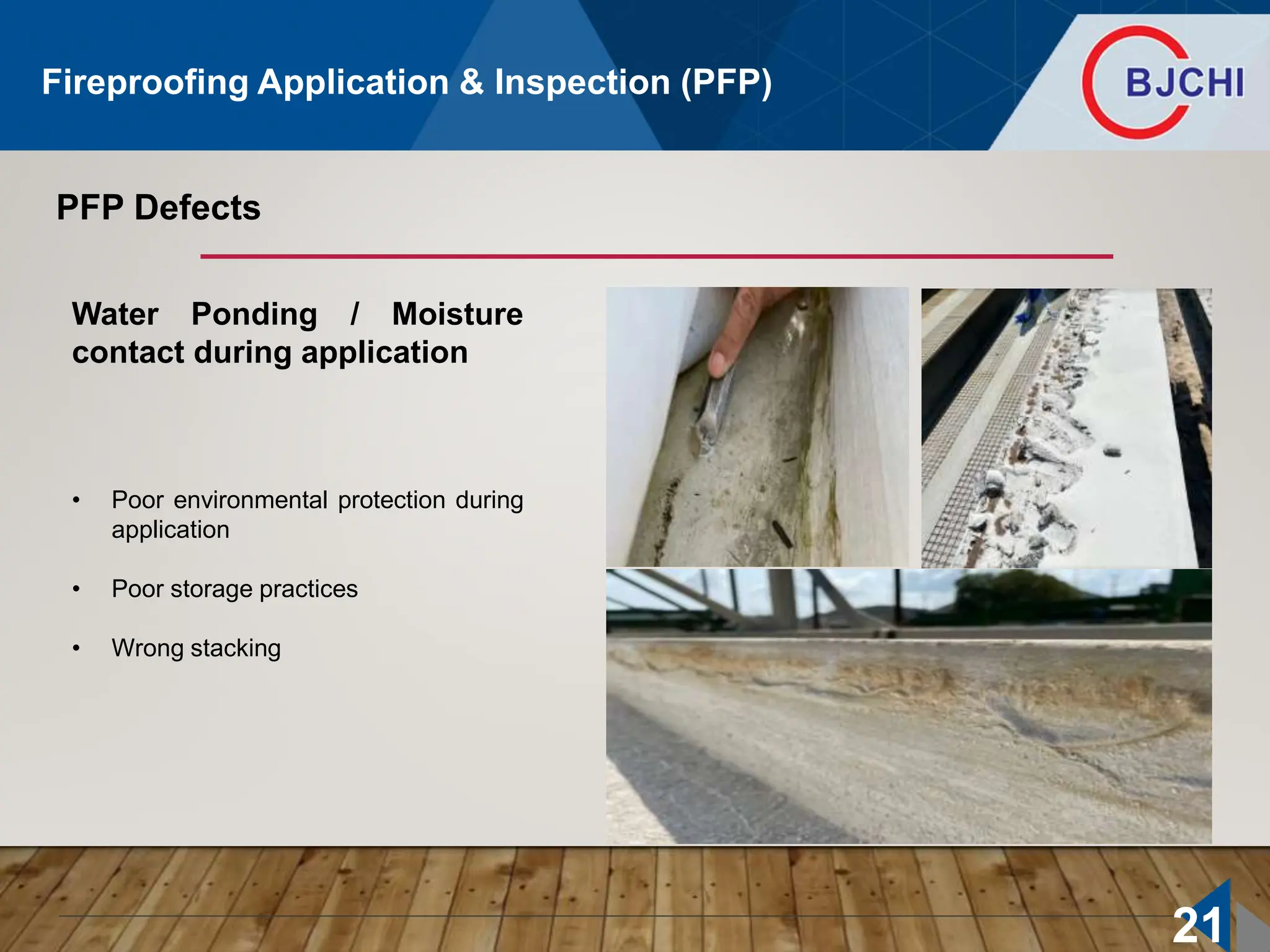

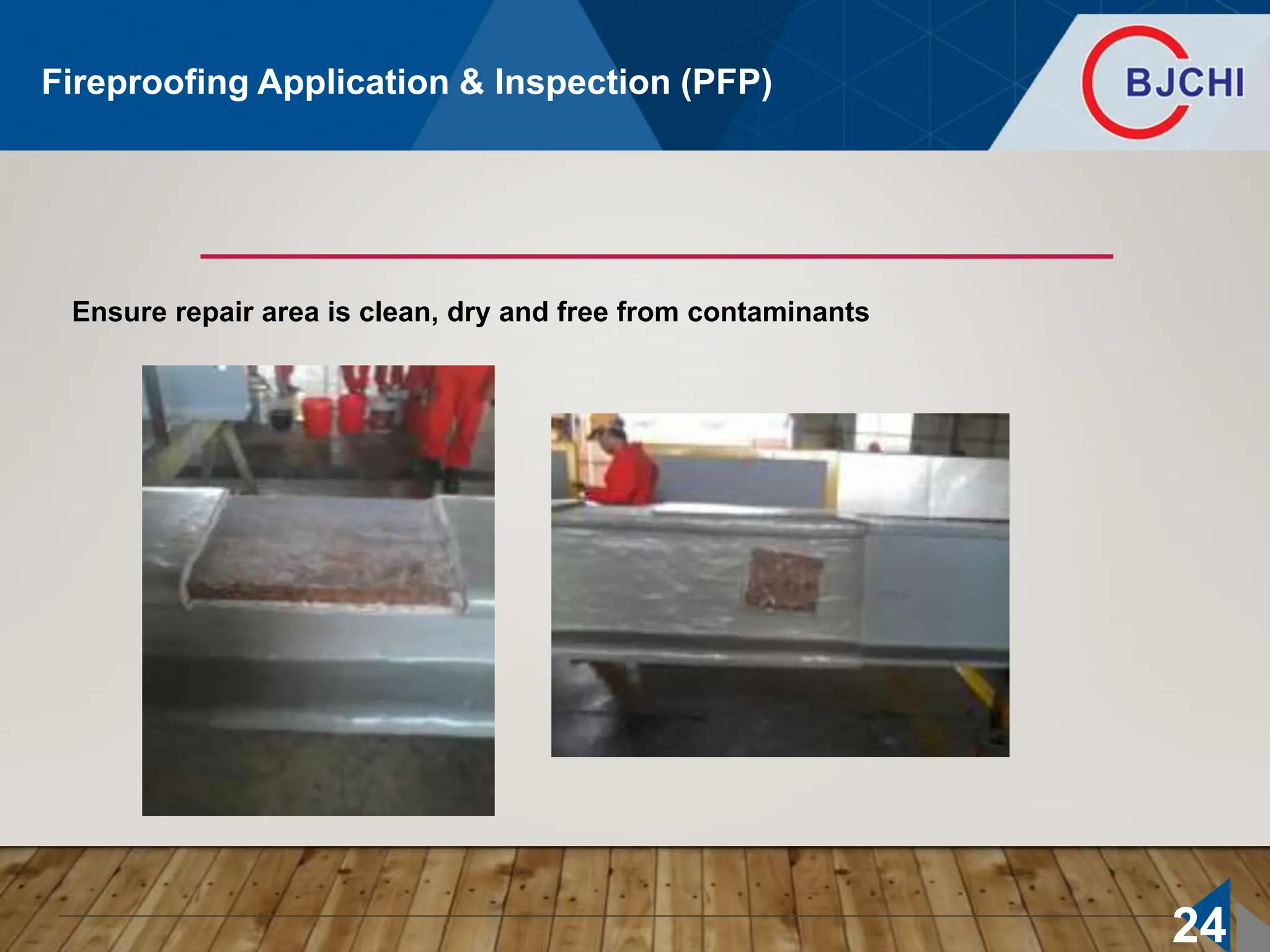

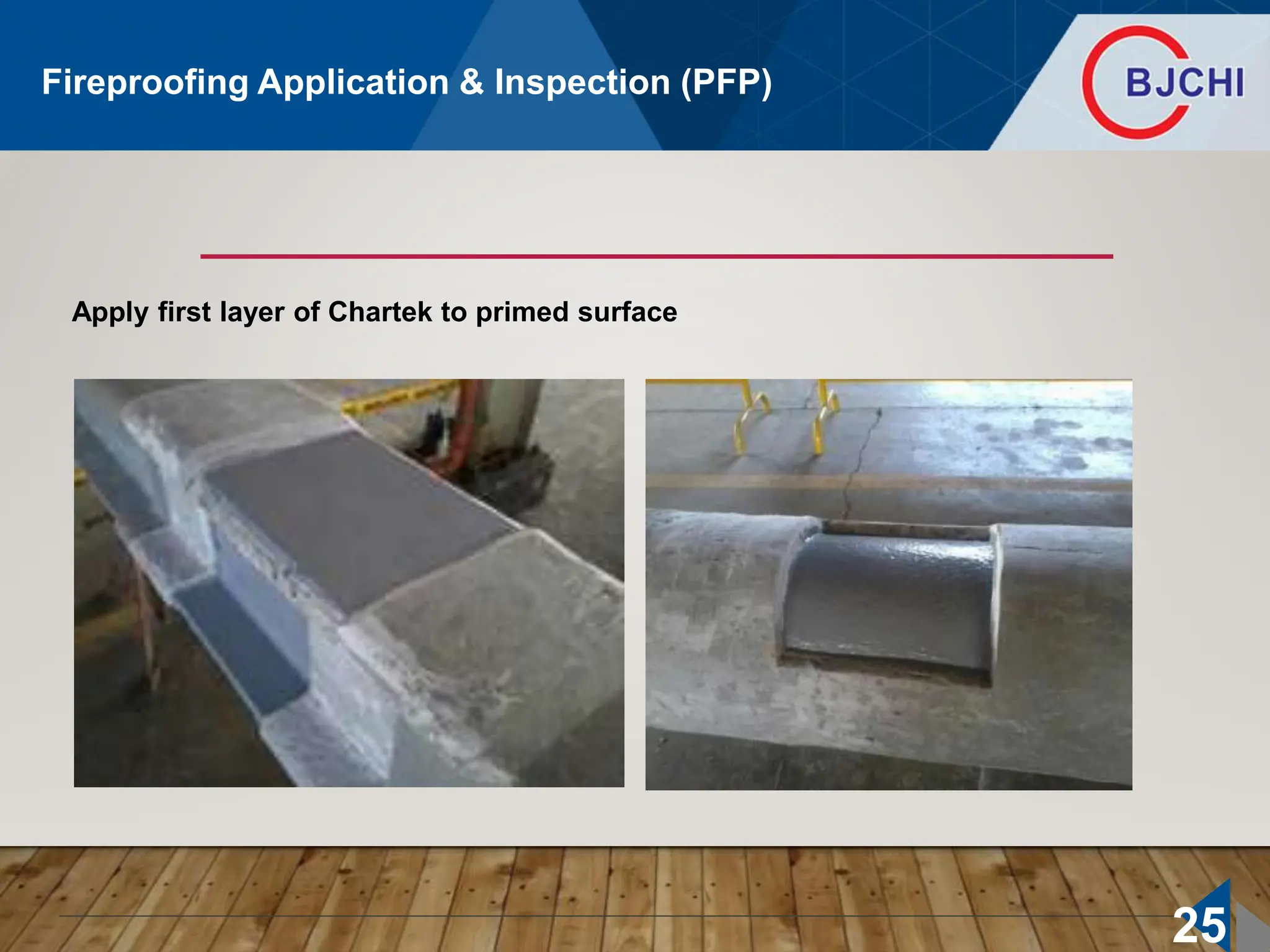

This document provides guidelines for applying and inspecting passive fire protection (PFP) using Chartek, an intumescent fireproofing material. It discusses surface preparation, the use of primers and mesh reinforcement, application methods including spraying, and inspection requirements at each stage. Repairs to Chartek involve removing damaged areas and reapplying the material in multiple coats over primer and mesh to meet thickness specifications. Regular quality control inspections are emphasized throughout the application and curing process to ensure the fireproofing is applied correctly.