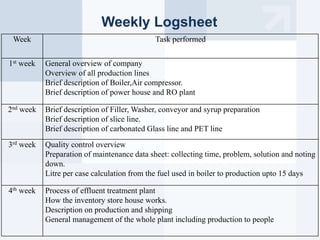

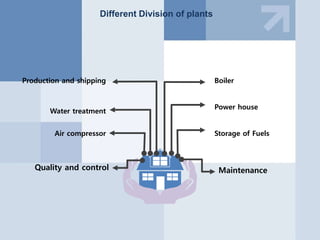

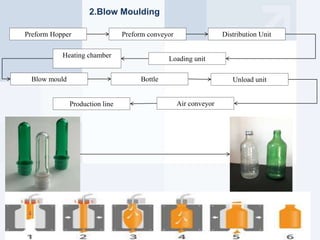

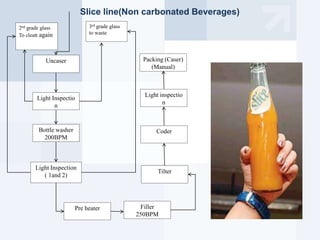

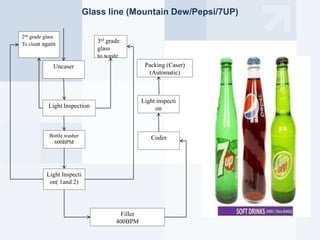

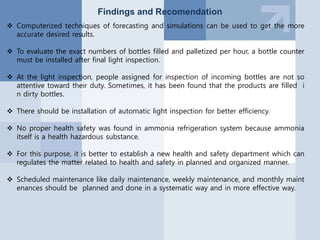

Varun Beverages Pvt. Ltd. is a franchisee of PepsiCo beverages in Nepal. It has a manufacturing plant in Kathmandu with 500 employees. The plant produces carbonated drinks like Pepsi, 7Up, and Mountain Dew as well as non-carbonated drinks like Tropicana and Mirinda. The internship summary describes the company's production processes including syrup preparation, blowing, filling, and packaging lines. It also discusses the plant's utilities like water treatment, power generation, air compression, and quality control procedures. The intern makes recommendations to improve production tracking, health and safety, and maintenance management.