Ammonia Refrigeration System Set up and Parameters

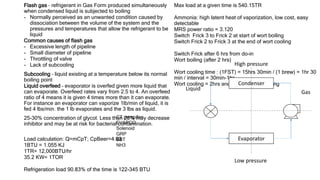

- 1. Flash gas – refrigerant in Gas Form produced simultaneously when condensed liquid is subjected to boiling - Normally perceived as an unwanted condition caused by dissociation between the volume of the system and the pressures and temperatures that allow the refrigerant to be liquid Common causes of flash gas - Excessive length of pipeline - Small diameter of pipeline - Throttling of valve - Lack of subcooling Subcooling – liquid existing at a temperature below its normal boiling point Liquid overfeed – evaporator is overfed given more liquid that can evaporate. Overfeed rates vary from 2.5 to 4. An overfeed ratio of 4 means it is given 4 times more than it can evaporate. For instance an evaporator can vaporize 1lb/min of liquid, it is fed 4 lbs/min. the 1 lb evaporates and the 3 lbs as liquid. 25-30% concentration of glycol. Less than 25% may decrease inhibitor and may be at risk for bacterial contamination. Load calculation: Q=mCpT; CpBeer=4.03 1BTU = 1.055 KJ 1TR= 12,000BTU/hr 35.2 KW= 1TOR Refrigeration load 90.83% of the time is 122-345 BTU Max load at a given time is 540.15TR Ammonia: high latent heat of vaporization, low cost, easy detectable MRS power ratio = 3.120 Switch Frick 3 to Frick 2 at start of wort boiling Switch Frick 2 to Frick 3 at the end of wort cooling Switch Frick after 6 hrs from do-in Wort boiling (after 2 hrs) Wort cooling time : (1FST) = 15hrs 30min / (1 brew) = 1hr 30 min / interval = 30min-1hr Wort cooling = 2hrs and 15 mins after boiling Condenser Evaporator High pressure Low pressure Liquid Gas CT pump/fan EVAPCO Solenoid GRP BBT NH3

- 2. Condensate – a liquid state of water at saturated temperature that is formed when steam gives off its enthalpy, usually after heating process LSFo decreased SO2 by half (0.9%) 67% diesel 3 Pesos pricy than BFO 273 holes. 96 in length, 204.5 dia Minimun header temperature: 170F Fire tube boiler: Cheaper, limit pressure up to 25bars (350psi) 8,200-8,500 L/day Condensate recovery – 80% Condensate blowdown – TDS Blowdown – deposits and sludge, suspended solids <40ppb DO at deaeration 1:100 rise to length 30-50m, fall not less than 1.27cm in 3meters Every 15 meters condensate drip legs 3-5 meters pipe support COC=Boilerwater TDS/Boiler feedwater TDS Pilot flame – 25 seconds Thermostatic – variation in temperature Mechanical – difference in specific gravity/density Thermodynamic – volumetric and pressure difference Pchem 100x – prevents sludging of strainers and filters, prevents formation of sticky resin, improves combustion efficiency Pchem500fs – increase tolerance of blending heavy fuels, inhibits storage tank sludge, reduce Nox and Sox emissions Steam supply: 6 hrs before – packaging 2 hrs before – brewing 34.5 lbs steam/hr = 1Bo. HP = 9.81 KW Level switches: microswitch and kasuga 13.009 kg steam/li fuel 2L pchem500fs/16,00 LSFO Condensate recovery = (feedwater-make up)/feedwater CA150 - phosphate indicator CA900+ - sulfate indicator 450 – 500 liters to create steam

- 3. Ammonia: Boils at -28F Freezes at -107F CO2 compressor - Every 6 month servicing of intercooler and aftercoooler - Suction and discharge valves, valve plates - Piston ring inspection - Oil analysis and change oil Iodine number of deodorizer not less than 1000 Liquid ammonia receiver: 0.75cu.m. Glycol chiller: 12TOR Ammonia compressor: 12TOR Ammonia condenser: 12TOR CO2=8pesos/kg °P x 0.412 x hL Ferm Scrubber – 11ft. 4 in. 2ft dia Deodorizer – 6ft. 8 in. 2ft dia Drier – 8ft. 4 in. 1ft dia Vaporizer – 10ft. Length Expansion tank – 11ft. 3 in. scrubber – 2.5-4L/1kg CO2 210 psi – Mycom trip off Co2 liquefies at -10F (-23.33C) 22 tons remaining after sold 2.0665 gms Glucose~1gm alcohol and 0.9565 CO2 Activated carbon: 4x12 coconut shell mesh. Replace if iodine number <1000 Activated alumina – replace if 50% reduction in size or off white color Booster – Necessary to overcome pipe friction and pressure drop across CO2 gas purifiers Quarterly sterilization of supply lines CO2 rec = ending – beginning + sold + consumed 25 tons – maximum storage tank level 90 tons – maximum nurse tank level CO2 rousing – 10 hrs

- 4. Positive displacement – compression accomplished through reduction of volume at the space Dynamic – compression accomplished through acceleration of the air by changing its momentum FAD/CFM – volume of air delivered to some specific point and converted back to ambient conditions at that location Refrigerated dryer – cannot go below 3°C/37.5°F, ISO air quality class 4 only Desiccant Drier: Pressure release Desorption Cooling Pressurizing Stand by Adsorption Using of lube air for spent grain conveying: - for lubrication - cost implication - more dense than dry air, better for conveying

- 5. Chlorinated Demi Brewing Softened R.Cl 0.7-0.8 0.3-0.5 0.4-0.6 Total Hardness 1 20-40 Silica 30 60 60 Calcium Hardness 7.0-10 Alkalinity 0.7-1.0 pH 7-10 6.5-7.5 6.5-7.5 Softened water – no way to correct chlorine Inject air around 15% to precipitate iron to remove iron from water, pH=6.8 At least 50% free board for backwashing cation and anion FMA(yellow) – alkalinity(peal orange) – methyl orange indicator Total hardness(blue) – 2ml pH buffer 10 – EBT Calcium hardness(violet) – 2ml 1 normal NaOH – murexide BOD – degree of pollutant, amount of oxygen needed to treat organic pollutants of wastewater. Indicator of pollution Influent Lagoon2 Lagoon3 Lagoon4 Lagoon5 Lagoon6 Effluent pH x x x x x x x COD x Wed Wed x BOD x Wed Wed x TSS x Wed Wed Wed x MLSS Wed Wed MLVSS Wed Wed COD 100 ppm BOD 50 ppm TSS 100 ppm Color 150 TCU pH 6.0-9.5 OAG 4 ppm Phosphate 1 ppm Nitrate 14 ppm Ammonia 4 ppm Total coliform 10000 MPN/ml Fecal coliform 400 MPN/ml MLVSS = sludge in aeration MLSS = microorganisms in aeration tank MLVSS = MLSS - ash Deepwell = slotted type filter screens Gaf filter – 150 microns Deepwell disinfection – semi annual. Recirculation fo Internal spray to bottle of hard water is detrimental a rinse jets and spotted bottles

- 6. Dissolve oxygen – a good indicator of water quality and capacity to support life form Biochemical oxygen demand – measure of oxygen required by microorganisms to decompose and stabilize the organic (and biodegradable) mater in the water Average influent volume 1500 m3.day with BOD of 500- 2,250 ppm Bar screen – 40pcs. 60 mm thick by 25 wide. Inclined at 60 deg. (reduce BOD by 10%) Presettling tank = 124.7 m3 retention of 1.6hrs. BOD reduction of 20%, desludged annually 12 inches disk type membrane Lagoon 4 desludging yearly Rest of the lagoons – every 2 years Wastewater contains vast quantities of bacteria and other organisms that originate in discharged wastes. The feeding activities of these organisms assist in decomposing wastewater. Total retention time = 10.94 days Sources of sludge: Water, dead bacteria, live bacteria, organic blown, dead fishes, inorganics, complex organics Discharge: 2,500 m3/day

- 7. Activity Frequency 1 Oil burner nozzle cleaning Weekly 2 Heat scanning of boiler Weekly 3 Flue gas analysis 2 weeks 4 Fuel strainer cleaning 3 months 5 Steam trap servicing 3 months 6 BFO pump servicing 4 months 7 Desooting of boiler 6 months 8 Boiler servicing yearly 9 BFO regulator servicing yearly 10 PRV calibration yearly Activity Frequency 1 System leak testing Weekly 2 Pre scrubber cleaning Monthly 3 Sterilization of CO² recovery line Monthly 4 CO² booster check-up and alignment Monthly 5 CO² compressor check-up and servicing 3 months 6 Dust filter cleaning 3 months 7 Sterilization of supply lines 3 months 8 CO² comp intercooler inspection and cleaning 6 months 9 Analysis of iodine number of deodorizer Yearly 10 Cleaning of CO² tanks Yearly Activity Frequency 1 Equipment leak testing weekly 2 Physical testing of cooling tower water weekly 3 EVAPCO servicing 28 days, one EVAPCO per week 4 Cleaning of separator body Monthly 5 Oil pot draining 4 months 6 PRV calibration yearly 7 Compressor calibration yearly Activity Frequency 1 Test run of diesel fire pump Weekly 2 Checking of bearing of water pumps Monthly 3 Manhole inspection Monthly 4 Checking of bed depth of ion exchangers 4 months 5 Deepwell disinfection 6 months 6 Cleaning of blended water tank and brewing water tank 6 months 7 Cleaning of unchlorinated, chlorinated and demi water tank Yearly 8 BIRM inspection Yearly 9 Deepwell inspection 2 years