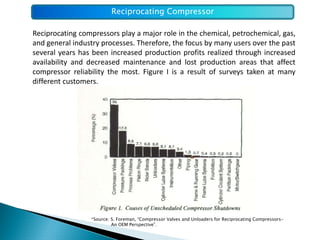

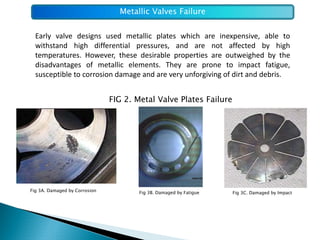

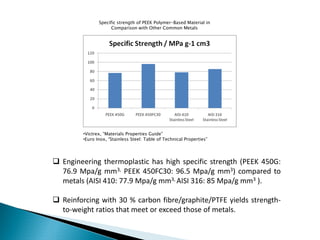

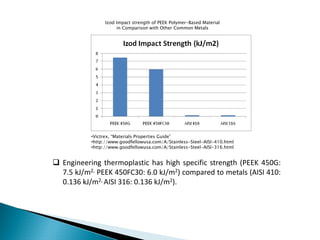

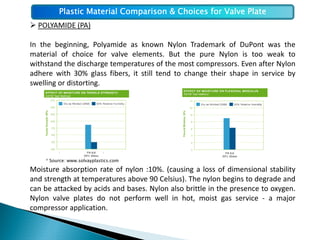

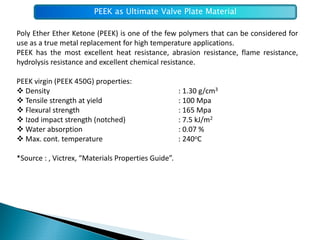

This document discusses materials for compressor valve plates, specifically for reciprocating compressors. It begins by identifying that compressor valves, pressure packing, piston rings and rider bands are the top causes of unscheduled shutdowns for reciprocating compressors. Metallic valve plates were initially used but suffered from issues like impact fatigue, corrosion damage, and inability to handle debris. Plastic materials like polyamide and polyetheretherketone (PEEK) emerged as replacements, with PEEK becoming the most commonly used material due to its high strength, temperature and chemical resistance, and ability to withstand impacts better than metals. PEEK provides more reliable performance for compressor valves.