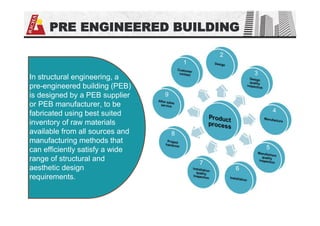

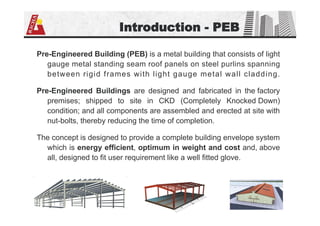

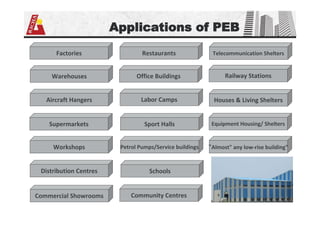

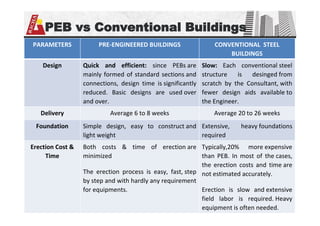

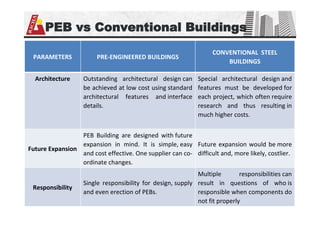

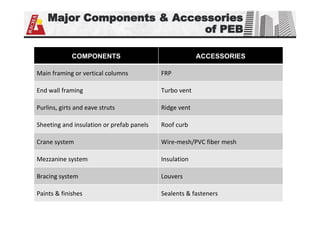

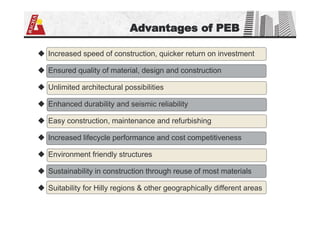

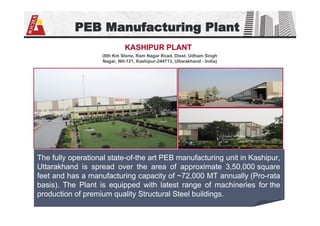

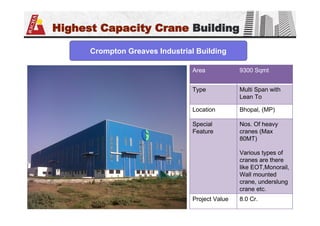

This document provides information about pre-engineered buildings (PEBs) produced by Richa Industries Limited. It defines PEBs and outlines their applications, advantages over conventional construction methods, and major components. These include their quick design and construction, cost-effectiveness, architectural flexibility, and durability. The document then describes Richa Industries' PEB manufacturing process, resources, and landmark projects delivering PEBs for various industrial and commercial clients across India.