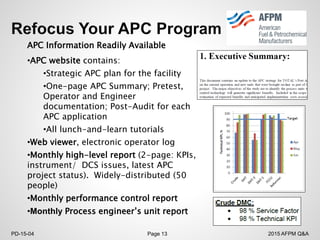

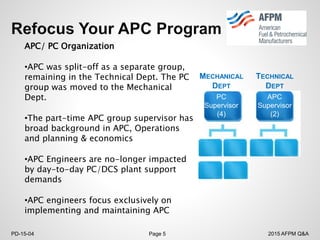

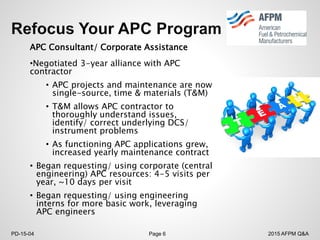

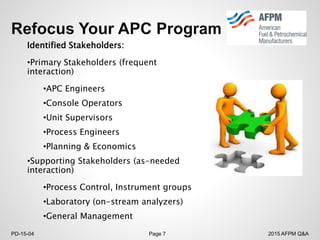

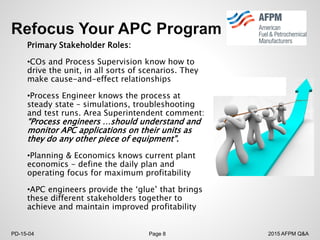

The document discusses how Total's Port Arthur Refinery improved its Advanced Process Control (APC) program by separating the APC and process control organizations, identifying key APC stakeholders, and engaging stakeholders in the design, implementation, and maintenance of APC applications. Key steps included dedicating APC engineers, providing stakeholder training, making APC information readily available, and establishing an APC program philosophy of high visibility and stakeholder accountability. These changes resulted in increased APC utilization rates and productivity improvements.

![2015 AFPM Q&APD-15-04 Page 12

Types of Stakeholder Training

•APC CBT (how MPC works) – different

modules for different stakeholders

•Lunch & learn – various stakeholders –

technical, conceptual information

•OJT (On-the-Job Training) – daily

interaction between CO, Operations

supervision and APC engineer

•Quarterly meetings

•With Operations supervision, process

engineer [for each major application]

•With Planning and Economics, Lab

•With Project Development, Process

Engineering supervisors

•CO formal training (part of requalification)](https://image.slidesharecdn.com/bceeca17-f947-4e8f-9acf-0bb96a6d8b10-151221204616/85/PD-15-4-Refocus_Your_APC_Program-Randy_Conley-Total-14-320.jpg)