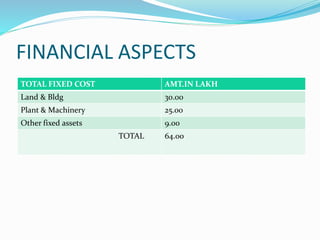

This document proposes establishing a mineral water bottling business. It discusses processing the water with minerals and flavoring, bottling 500 bottles per day in sterile conditions, and having production capacity of 1500 liters per day across 3 shifts. The market potential is described as high demand for bottled drinking water given unavailability of potable water. Financial analysis shows total capital investment of 82.43 lakh with projected annual profit of 37.10 lakh by selling 45 lakh bottles per year. Technical aspects cover the water treatment and bottling process, and meeting quality and production standards.