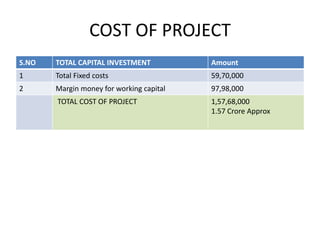

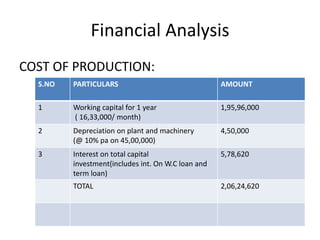

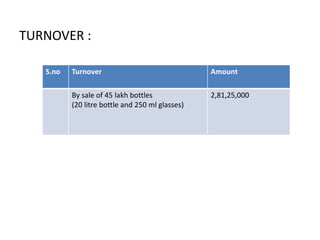

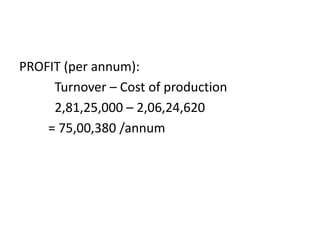

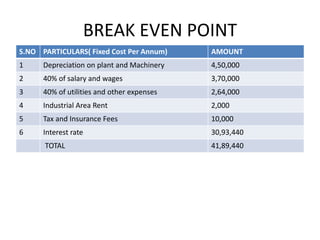

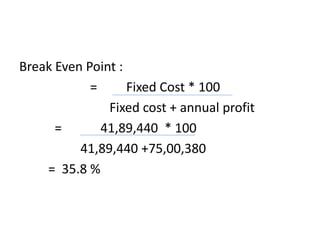

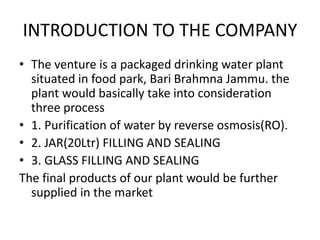

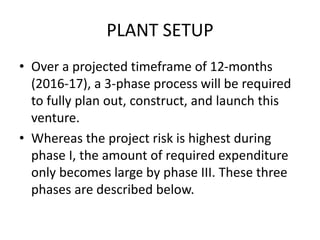

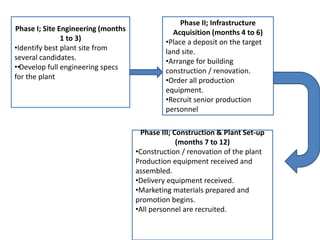

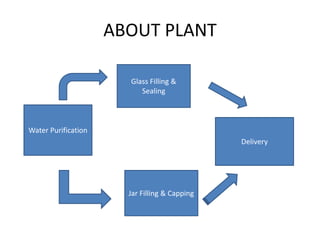

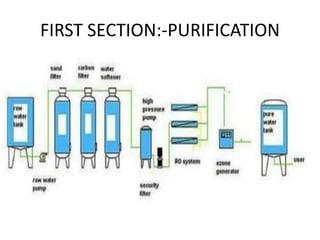

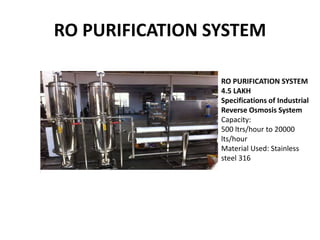

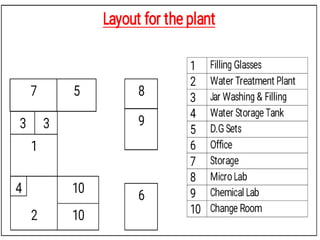

The document provides details about setting up a packaged drinking water plant called Puro Water Plant. It discusses the three phases of setting up the plant over 12 months, including site engineering, infrastructure acquisition, and construction. It also outlines the plant's purification process, key management positions, marketing plan, target markets, promotional strategies, pricing strategy, and financial appraisal with projected costs and profits. The overall goal is to establish a trusted brand of packaged drinking water in Jammu, India.

![Legal Documents Requirements

1. SSI REGISTRATION

The most basic Document needed for any small scale

industry in India. Once you have an SSI registration ,

you can avail many government facilities. Usually this is

available at the District Industries Centre , just check. It

is not very difficult to get this.

2. BIS Registration [ISI Mark Certificate]

This is mandatory for Packaged Drinking Water. The

Standard is – IS 14543](https://image.slidesharecdn.com/purowaterplant-160421083656/85/Puro-water-plant-15-320.jpg)