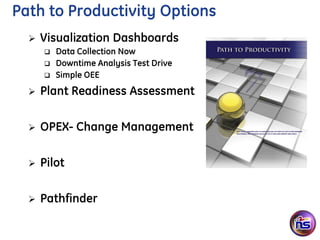

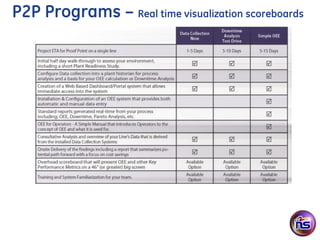

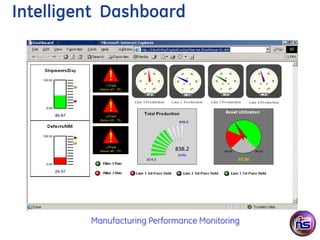

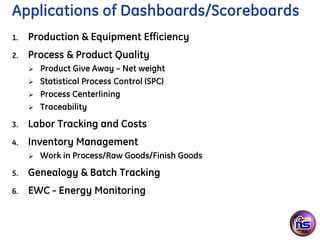

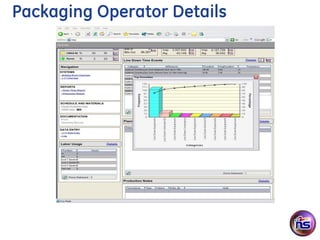

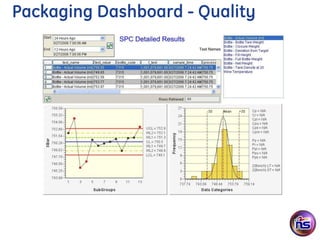

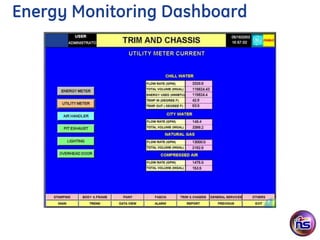

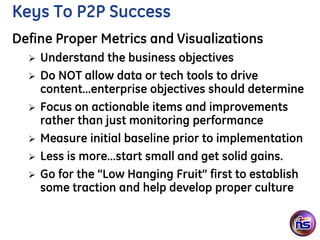

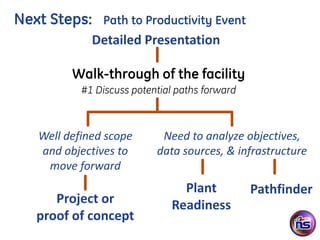

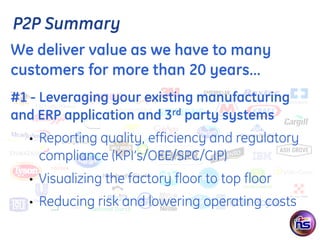

James Cox presented on a Path to Productivity (P2P) program for improving plant operations through data analytics and visualization. The presentation discussed developing a clear path forward by understanding the current state, desired future state, and reasons for change. The P2P program offers options like dashboards, assessments, pilots and guidance. Dashboards can visualize key metrics to monitor objectives like production efficiency, quality and costs. Examples showed real dashboards for packaging lines, energy use and overall performance. Keys to success include defining the right metrics and visualizations aligned to business goals, focusing on actionable insights, and starting with quick wins. The next steps discussed analyzing objectives, data sources and infrastructure to determine the best path forward for the client.