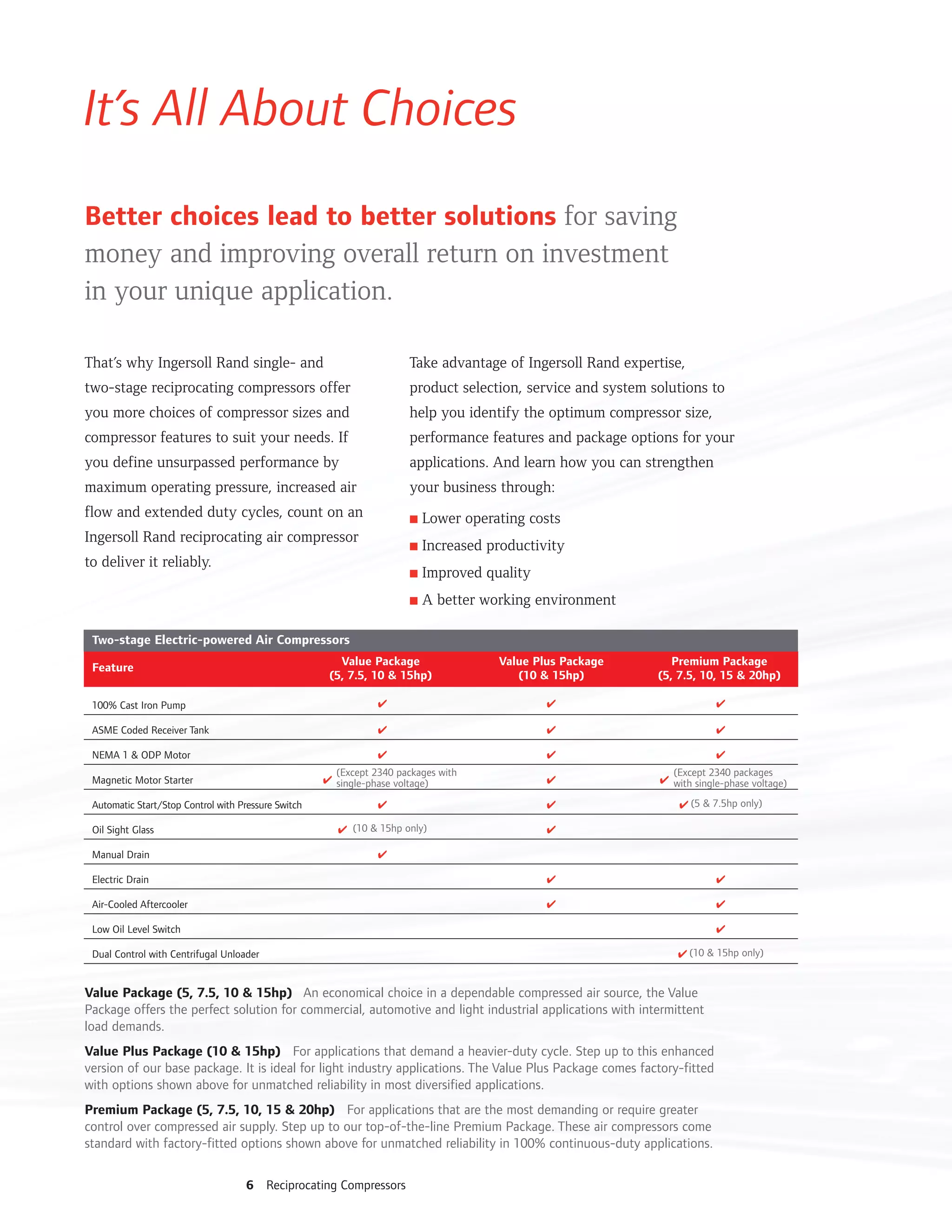

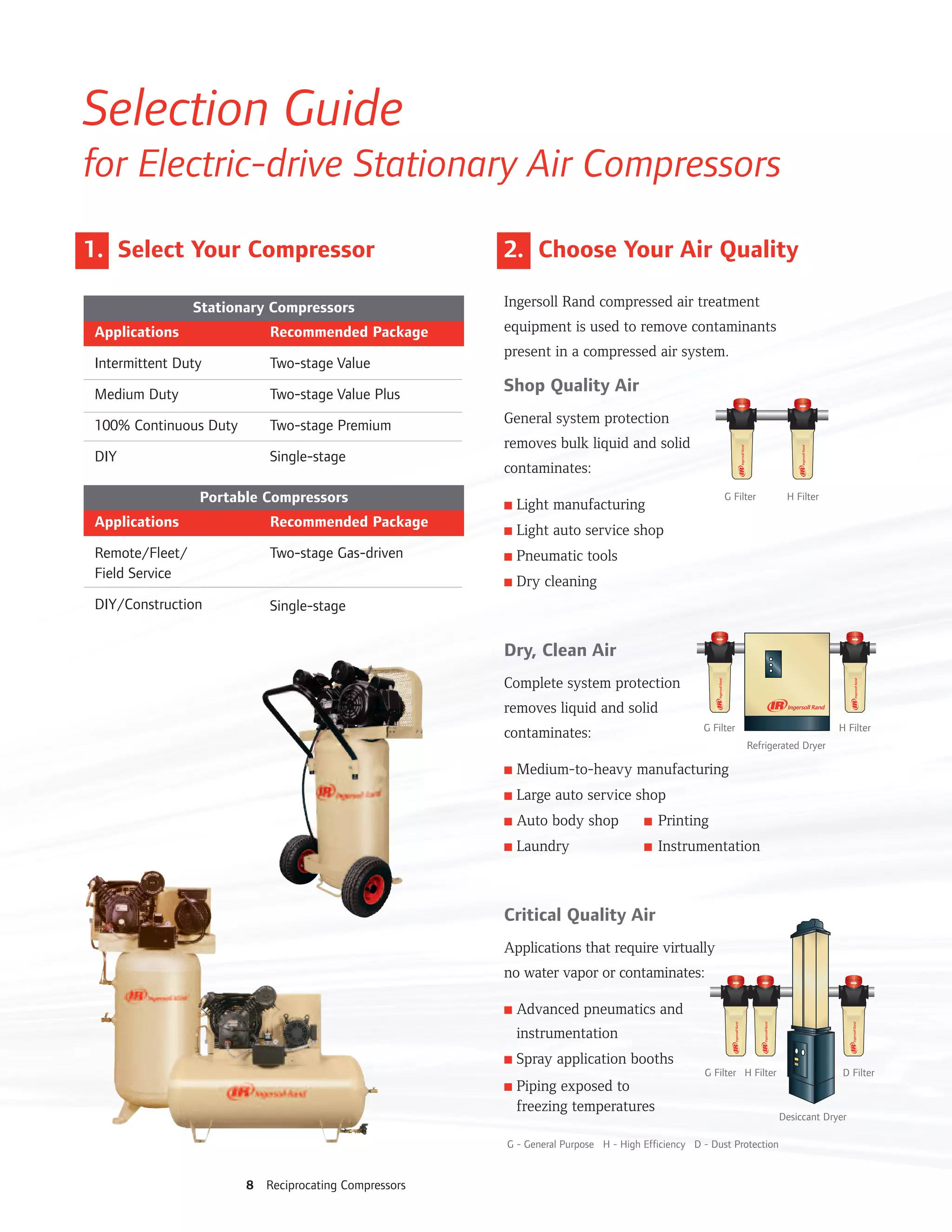

This document provides information on Ingersoll Rand reciprocating air compressors. It summarizes the company's history of innovation in compressor technology since 1872. It then provides details on their single-stage and two-stage compressor models for various applications, including packaged options, available voltages, dimensions and other specifications. The document emphasizes Ingersoll Rand compressors' efficiency, reliability and longevity through proven design and enhancements over many decades.