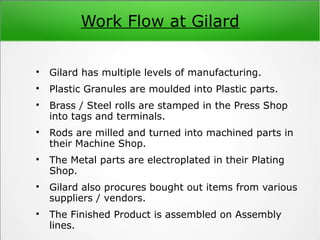

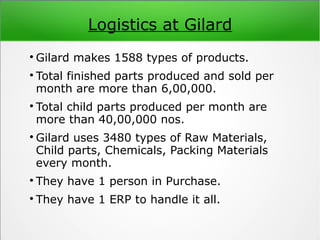

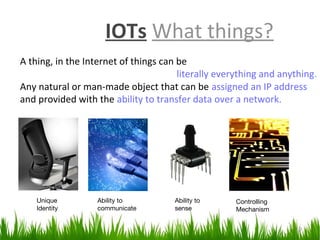

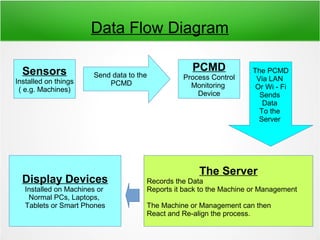

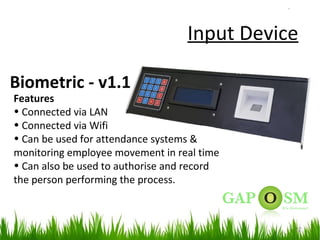

This document describes how Gilard Electronics Pvt. Ltd., an Indian electronics manufacturer, infused modern technology like digitization and IoT to improve competitiveness. It details how Gilard implemented an ERP system in 1987 to digitize operations like production planning and inventory control. In 2015, Gilard upgraded to newer ERP technologies and added IoT sensors to digitally monitor and control manufacturing processes. Now Gilard's entire operations from new product development to sales and finance are digitized and integrated on a central database for real-time access and decision making. The digitization helps Gilard improve quality, productivity, efficiency and reduce costs to better compete in a challenging market.