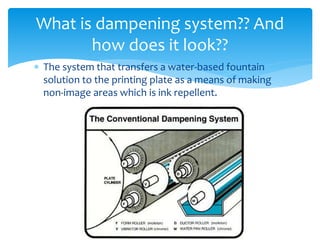

The document explains the operation of a dampening system used in printing, which transfers a water-based fountain solution to the printing plate to create ink-repellent non-image areas. It details the components of the dampening unit, including four main types of rollers: fountain, ductor, oscillator, and form rollers, along with the function of each roller in the process. The system ensures even distribution of the dampening solution to the plate cylinder through a controlled mechanism involving speed variations and oscillation.