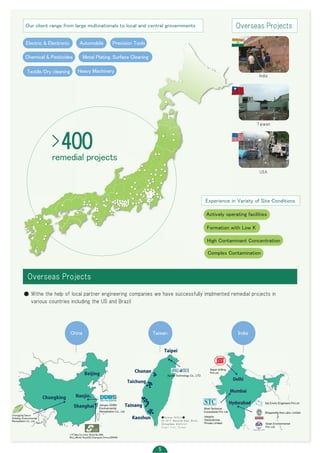

This document summarizes the services of a Japanese environmental remediation company. It specializes in remediating soil and groundwater contamination from volatile organic compounds, petroleum hydrocarbons, cyanide, heavy metals, and other pollutants. It has expertise in various disciplines relevant to remediation and an analytical laboratory. The company provides state-of-the-art site investigation and remedial technologies, both developed in-house and imported. It has experience with over 400 remedial projects in various countries.