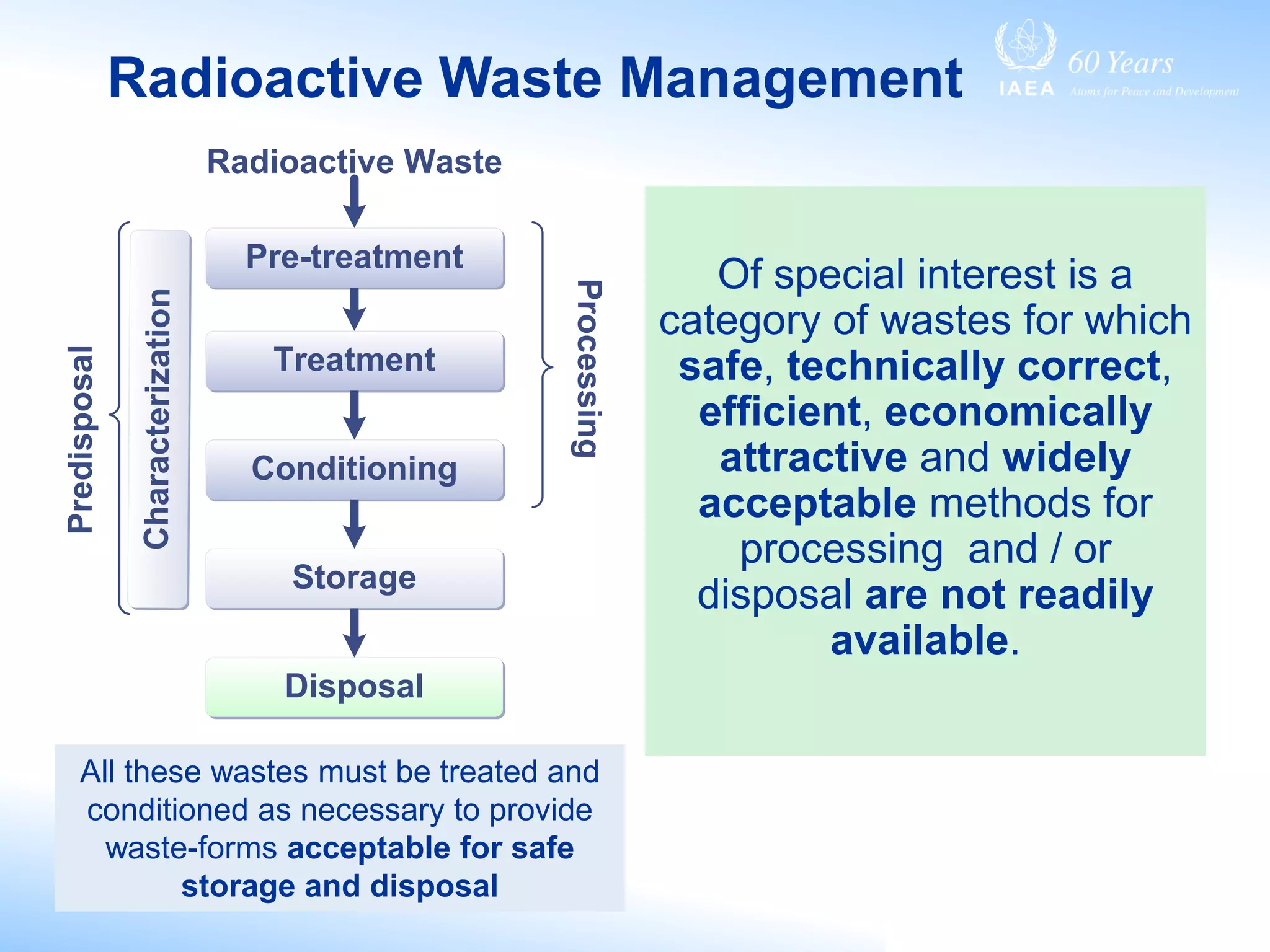

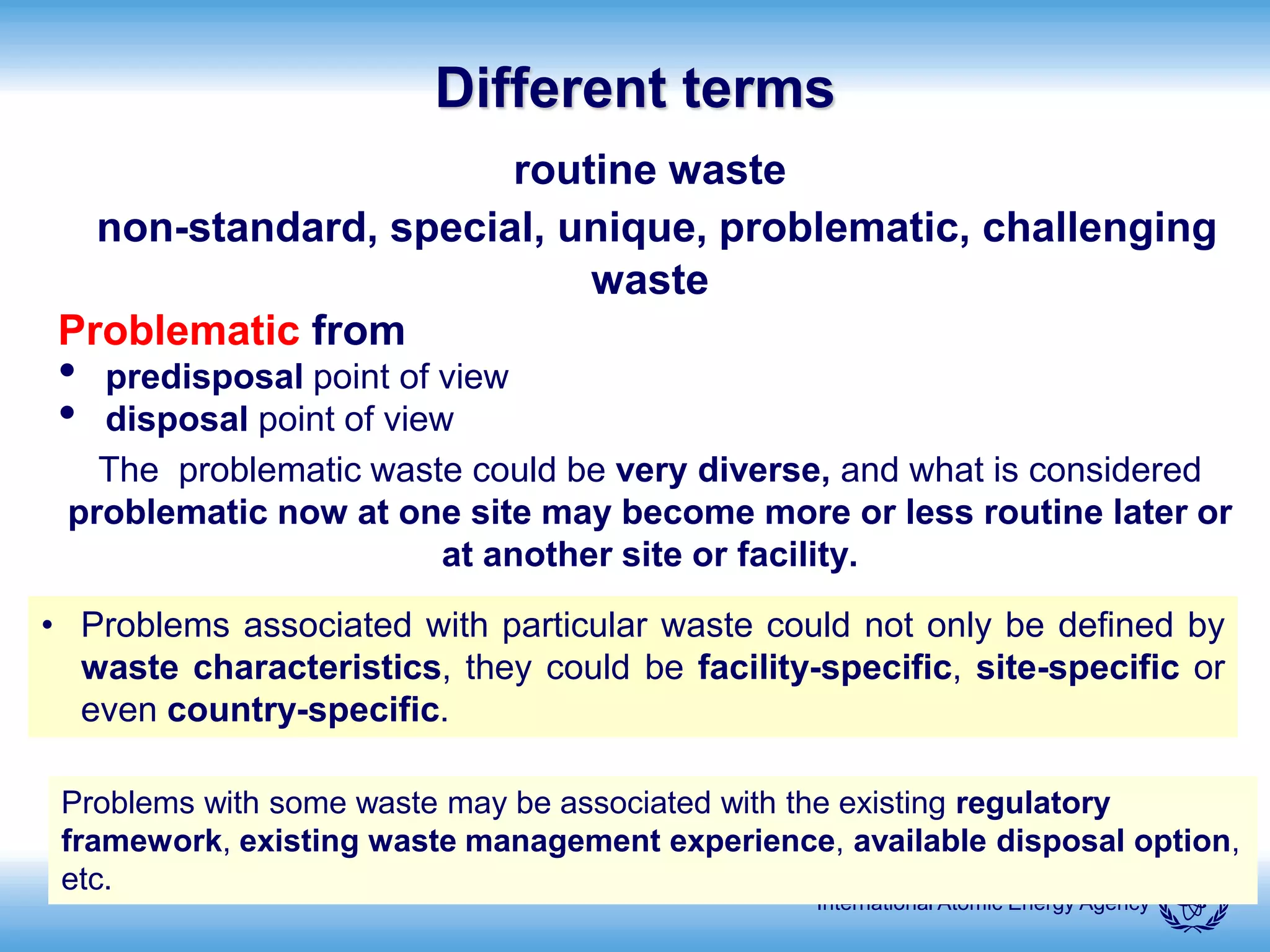

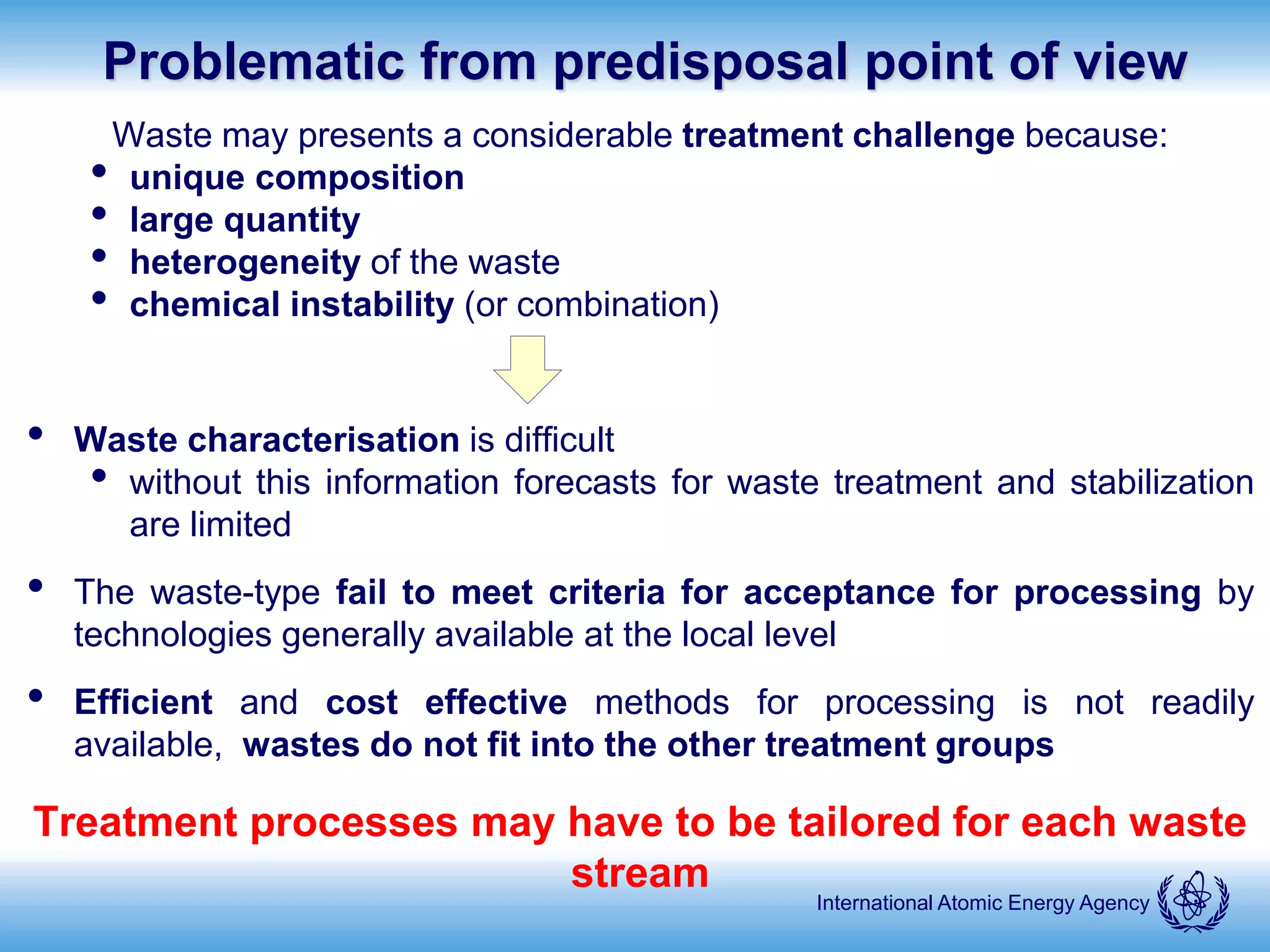

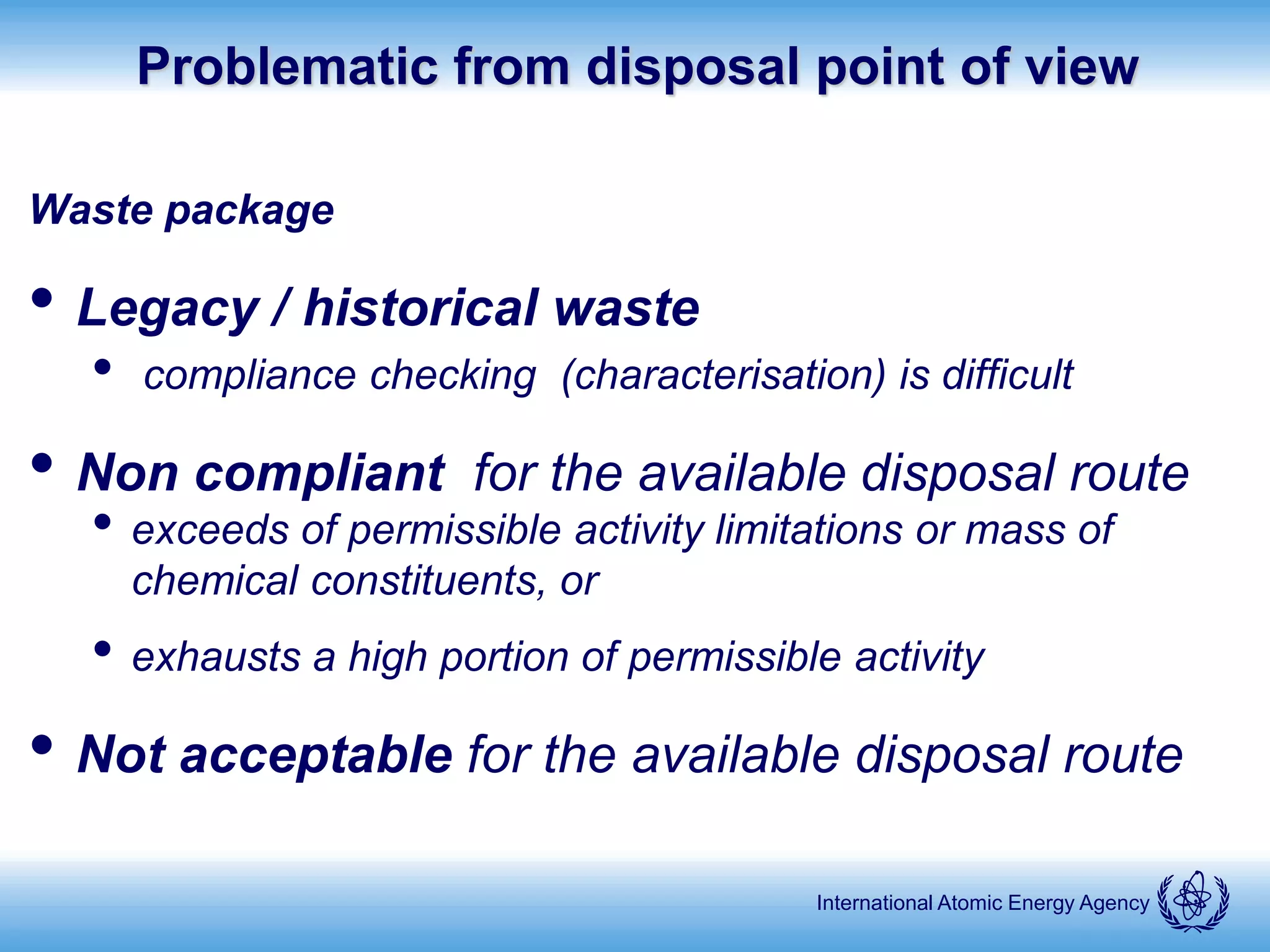

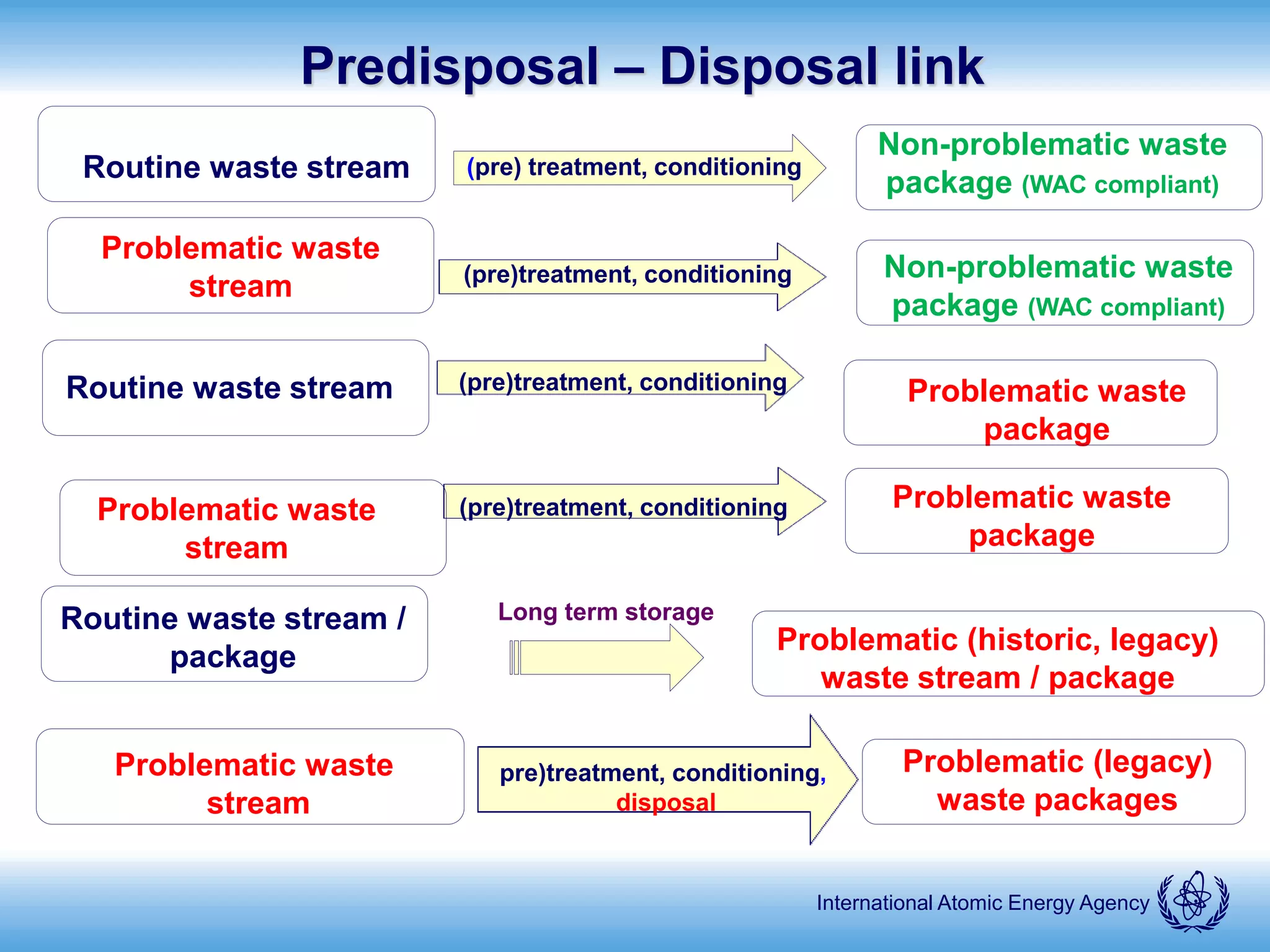

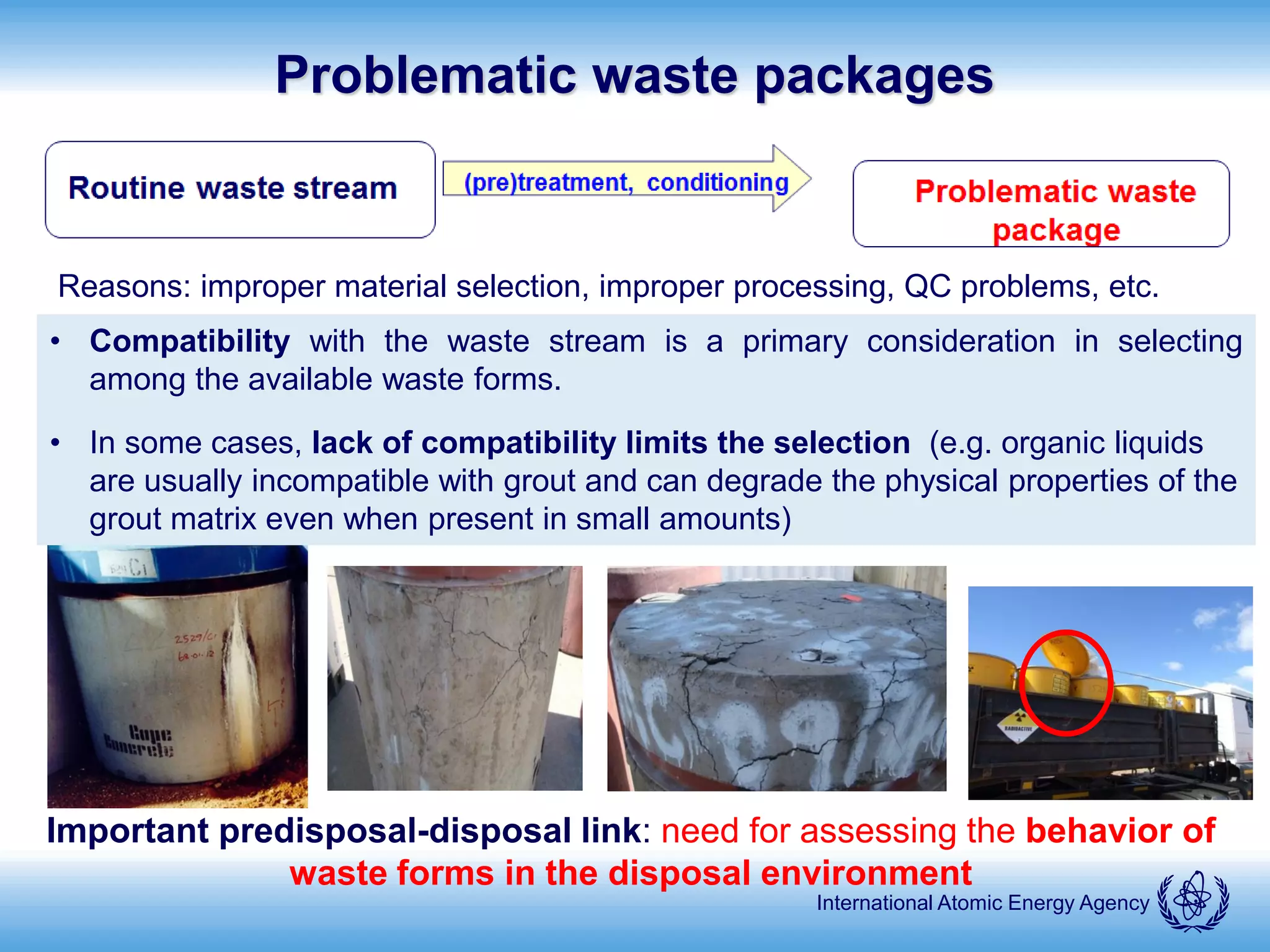

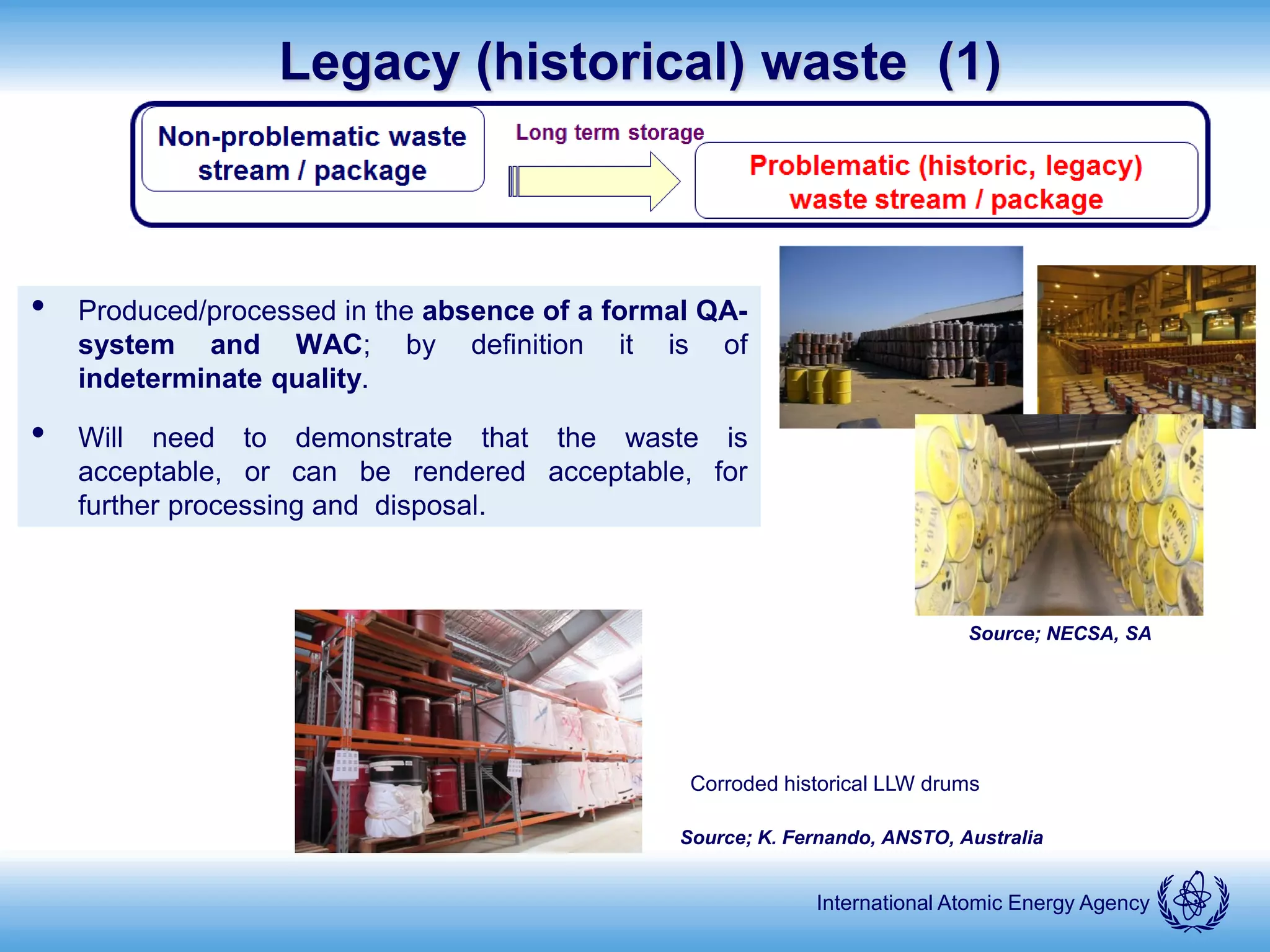

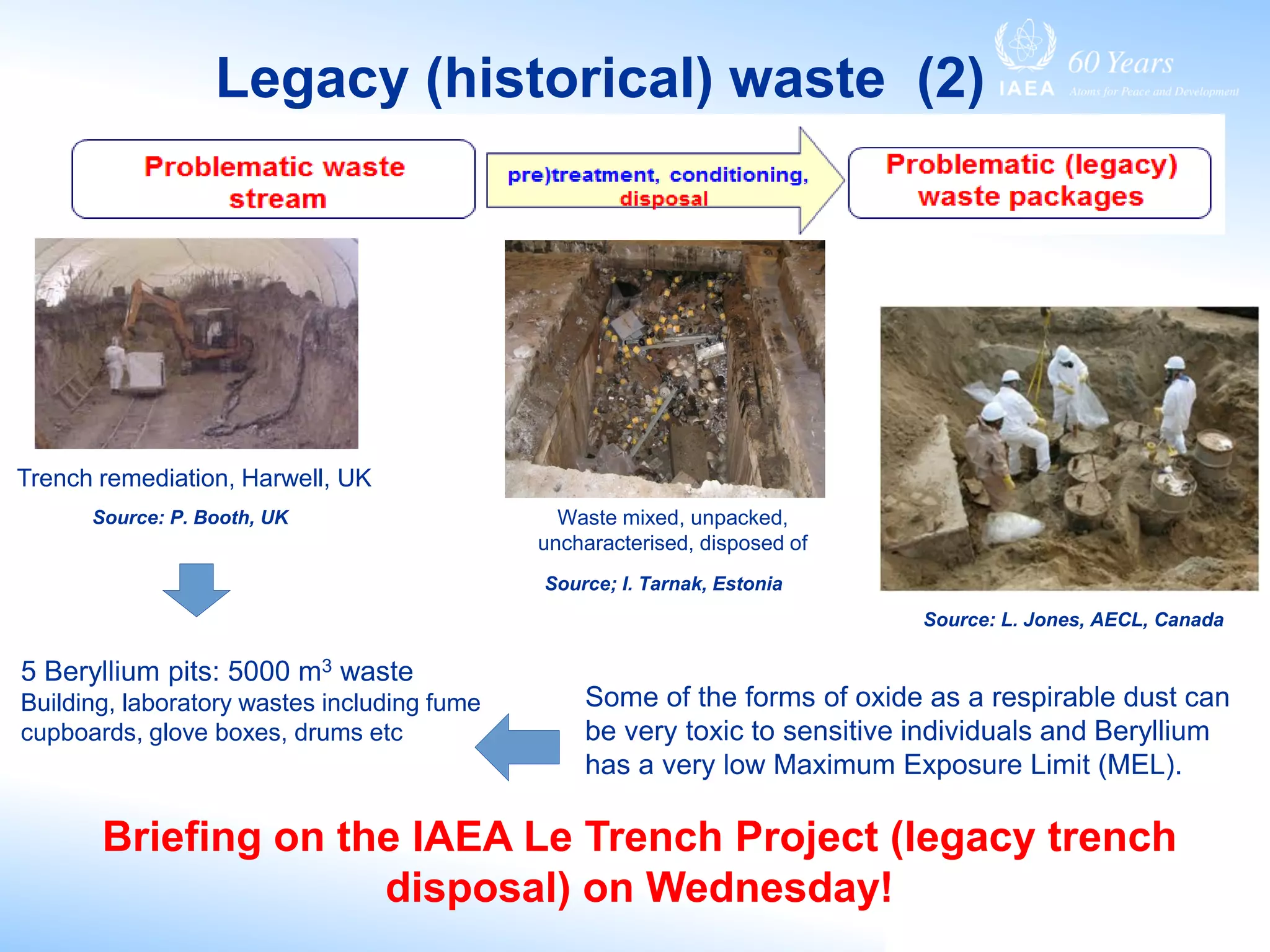

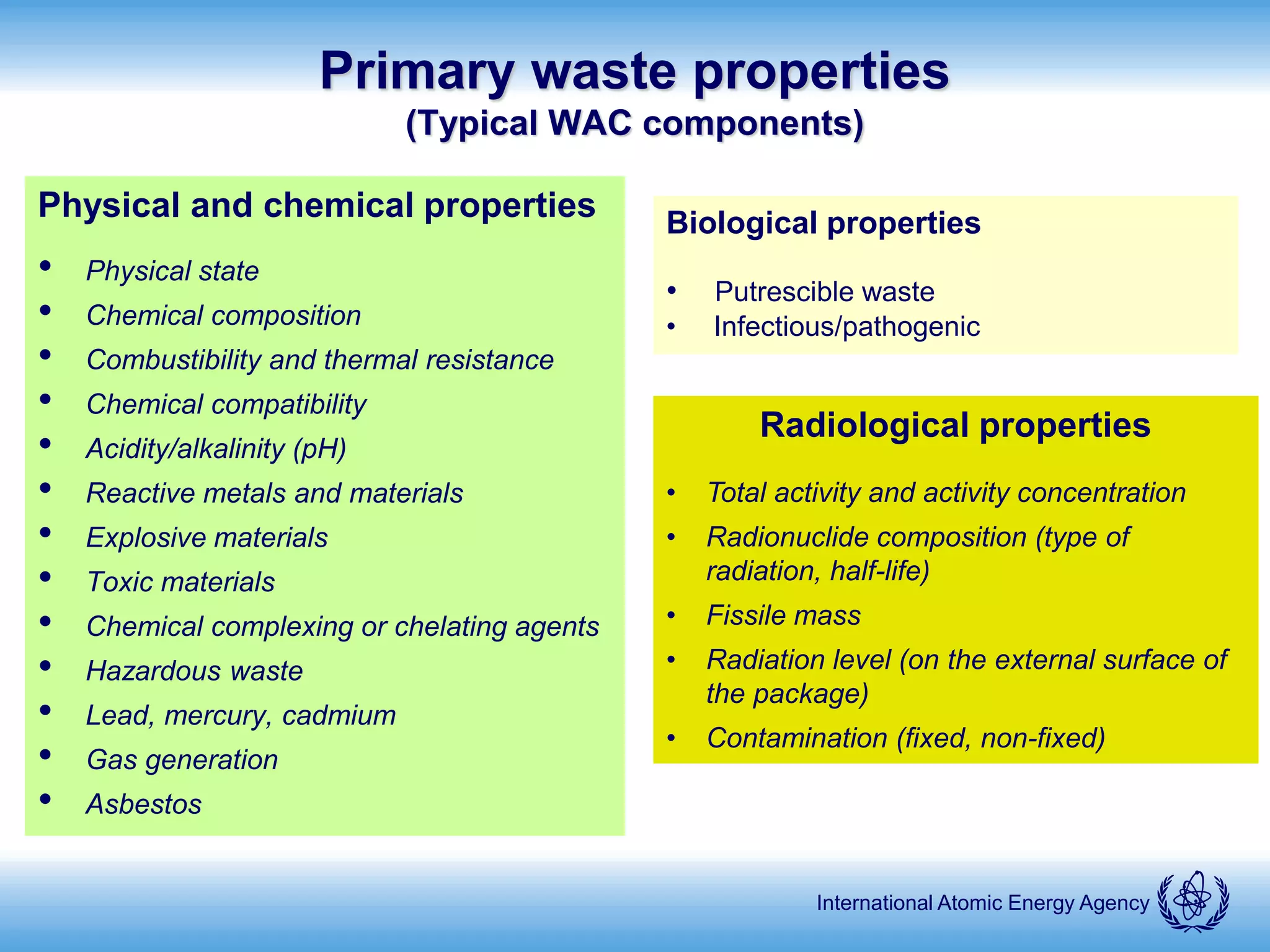

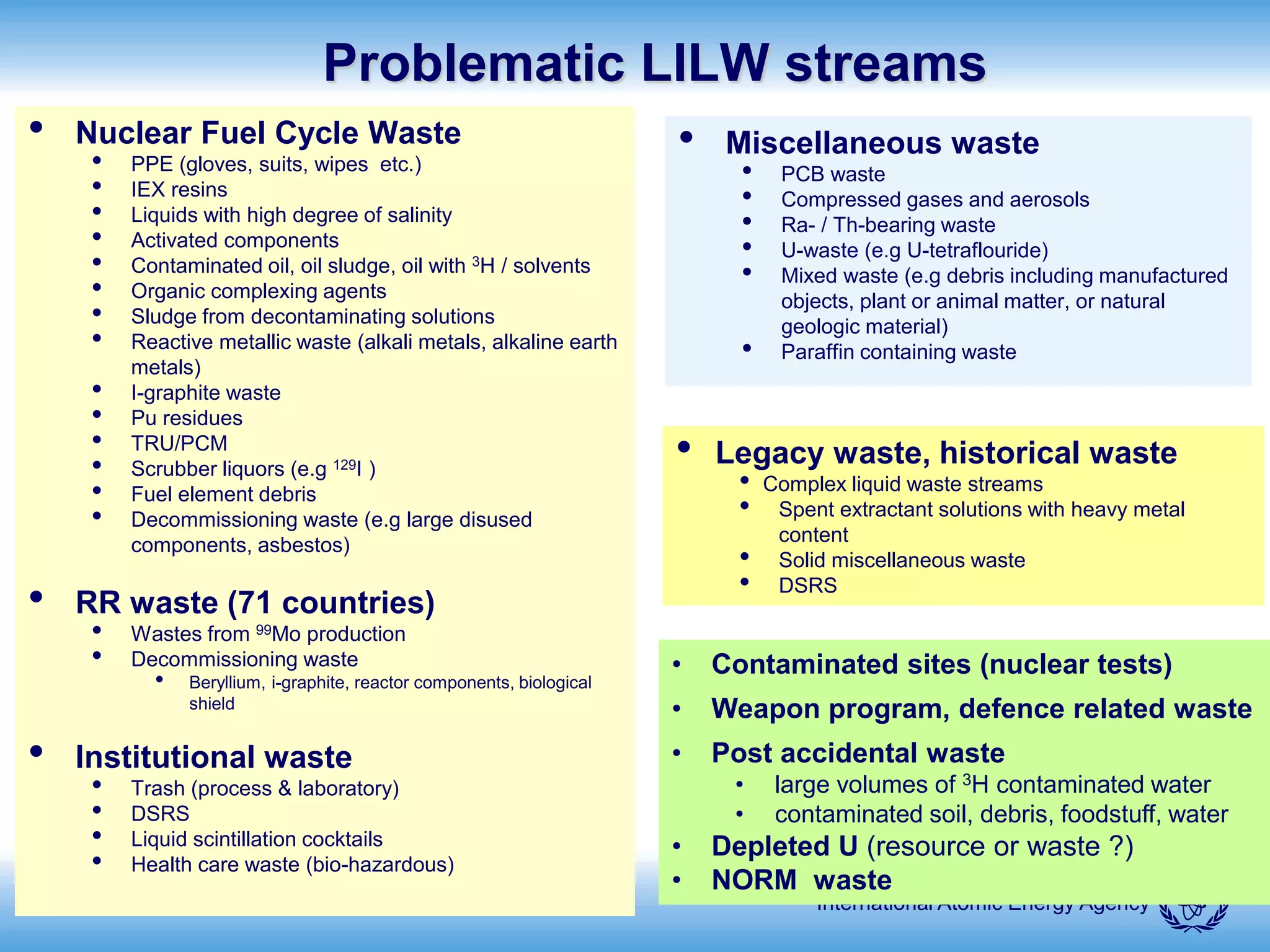

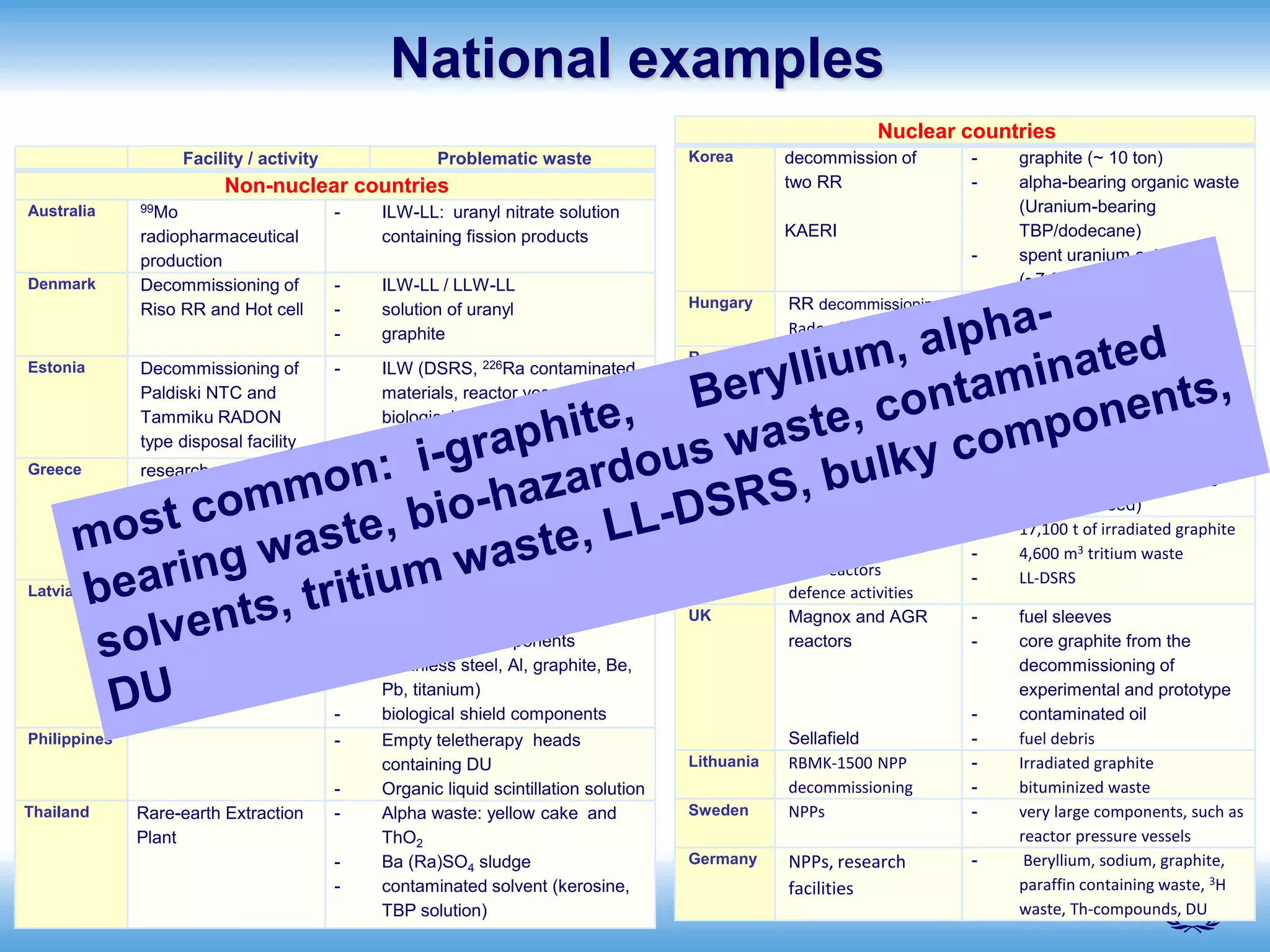

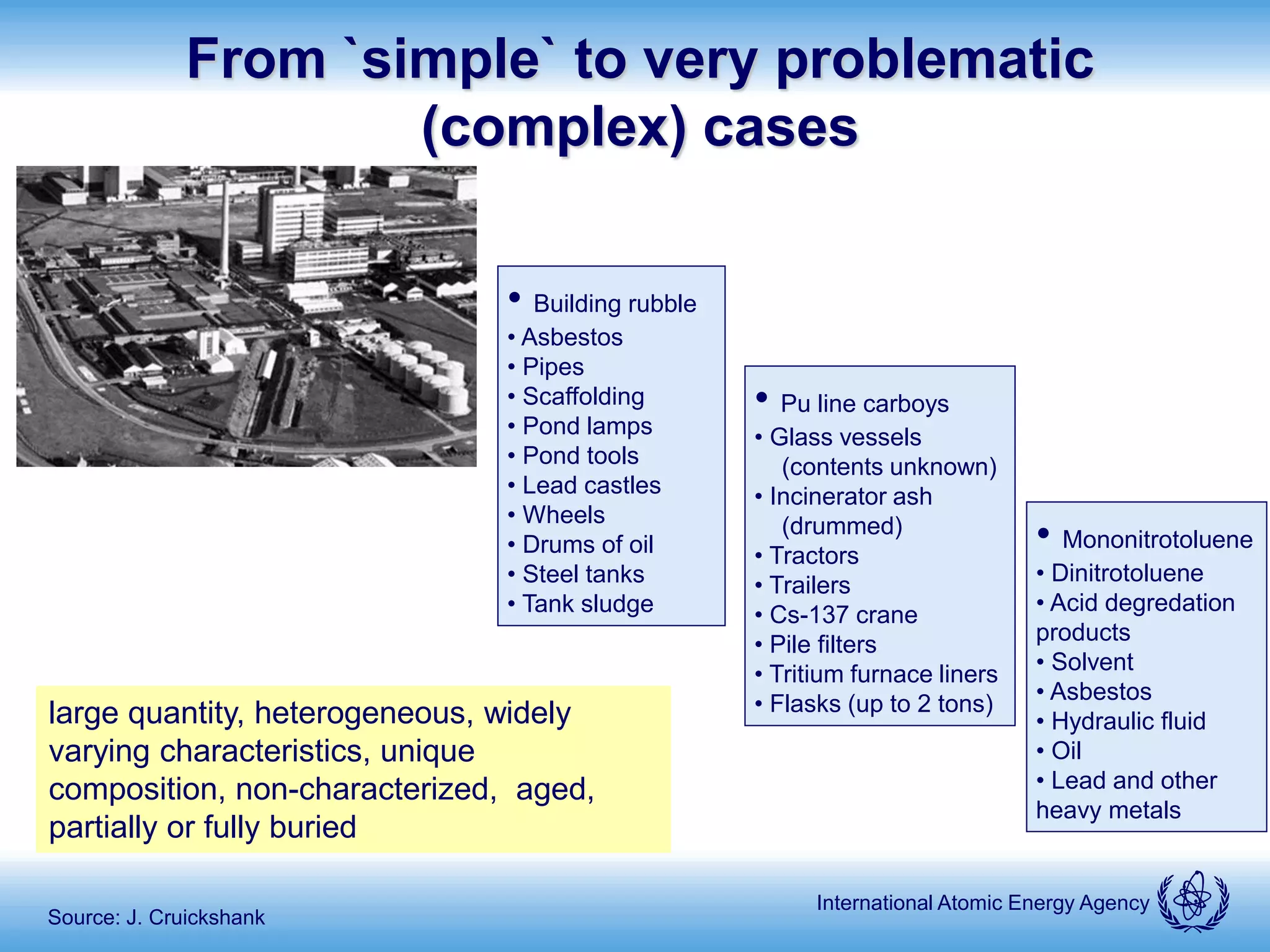

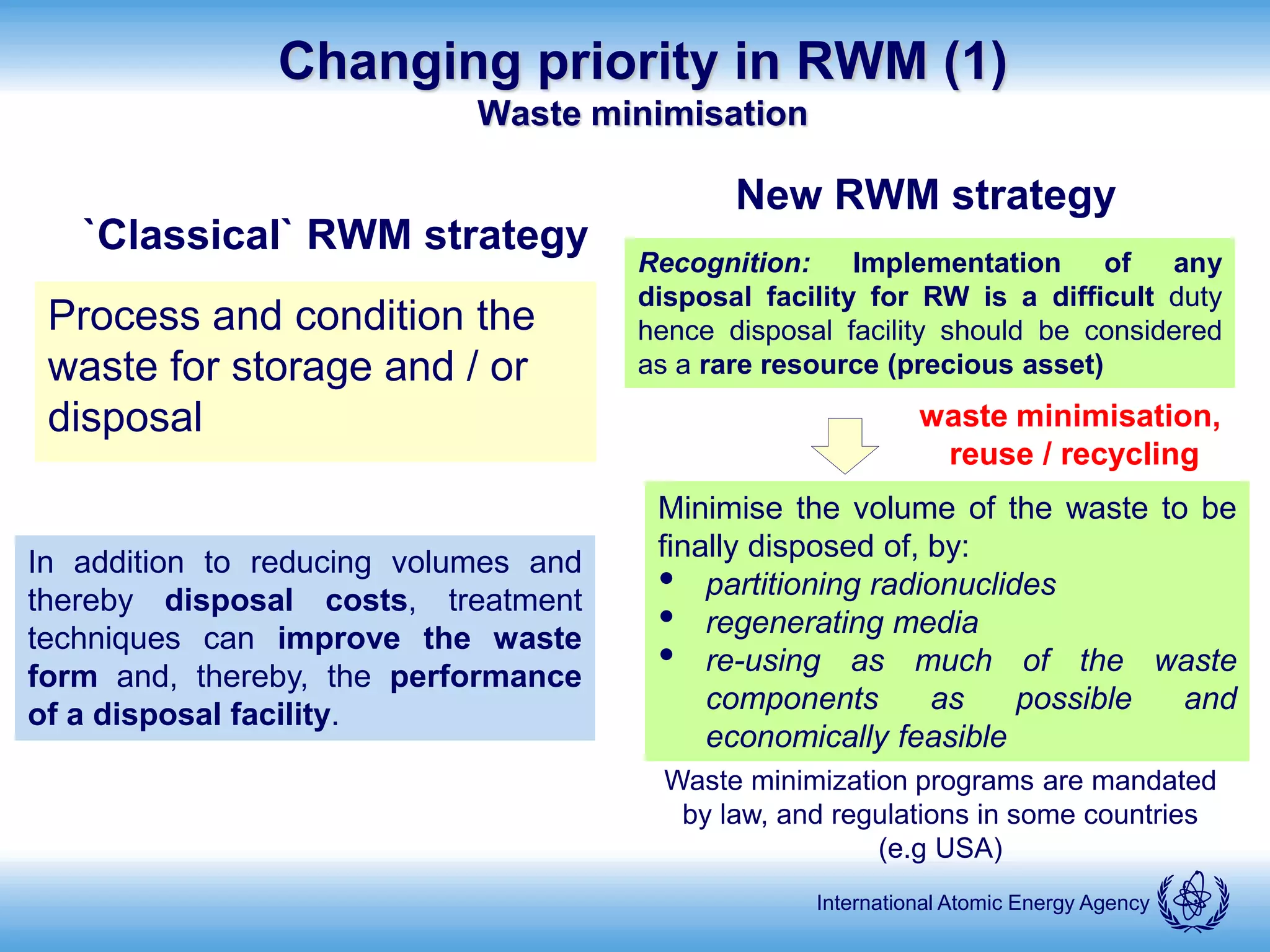

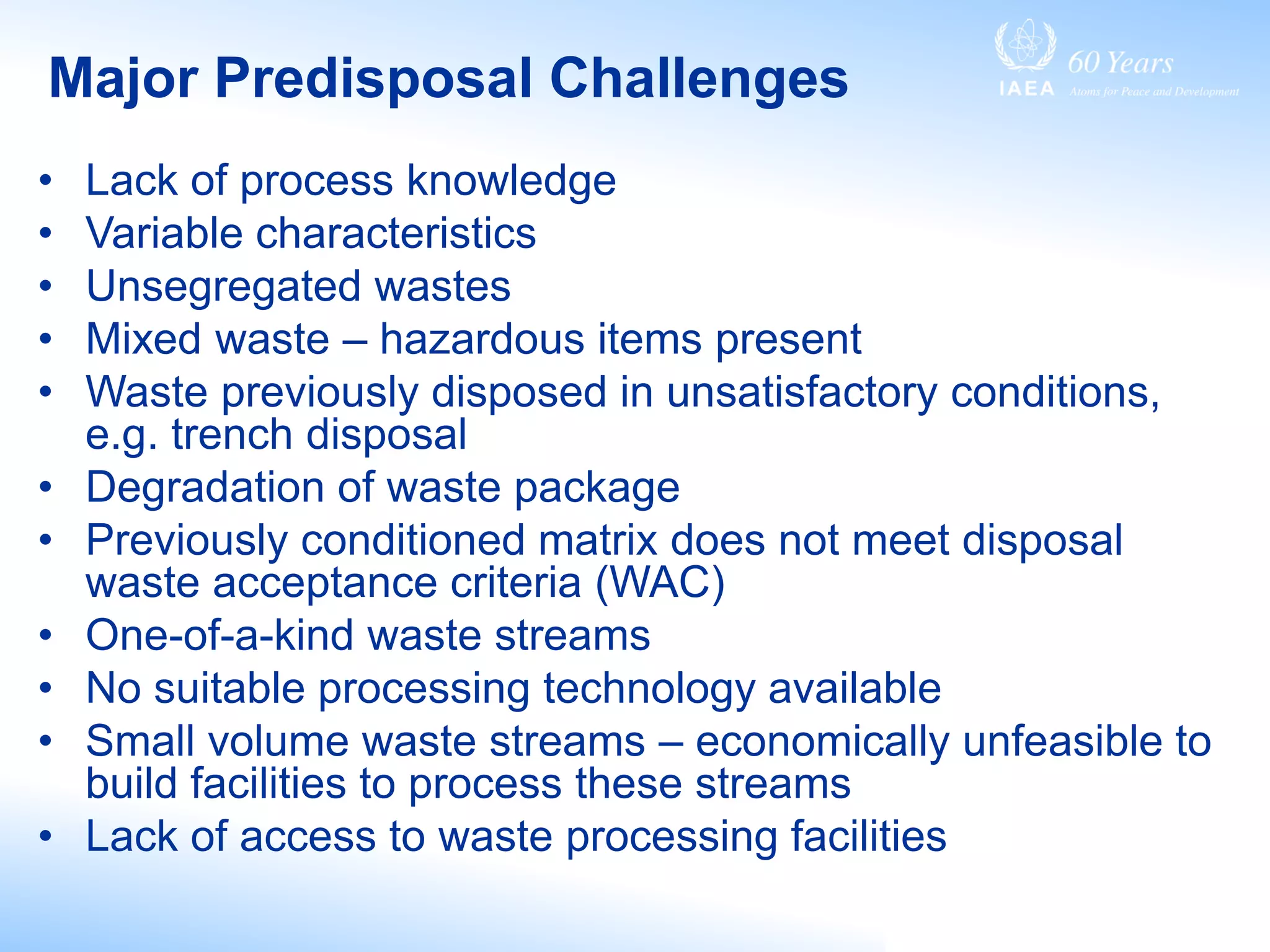

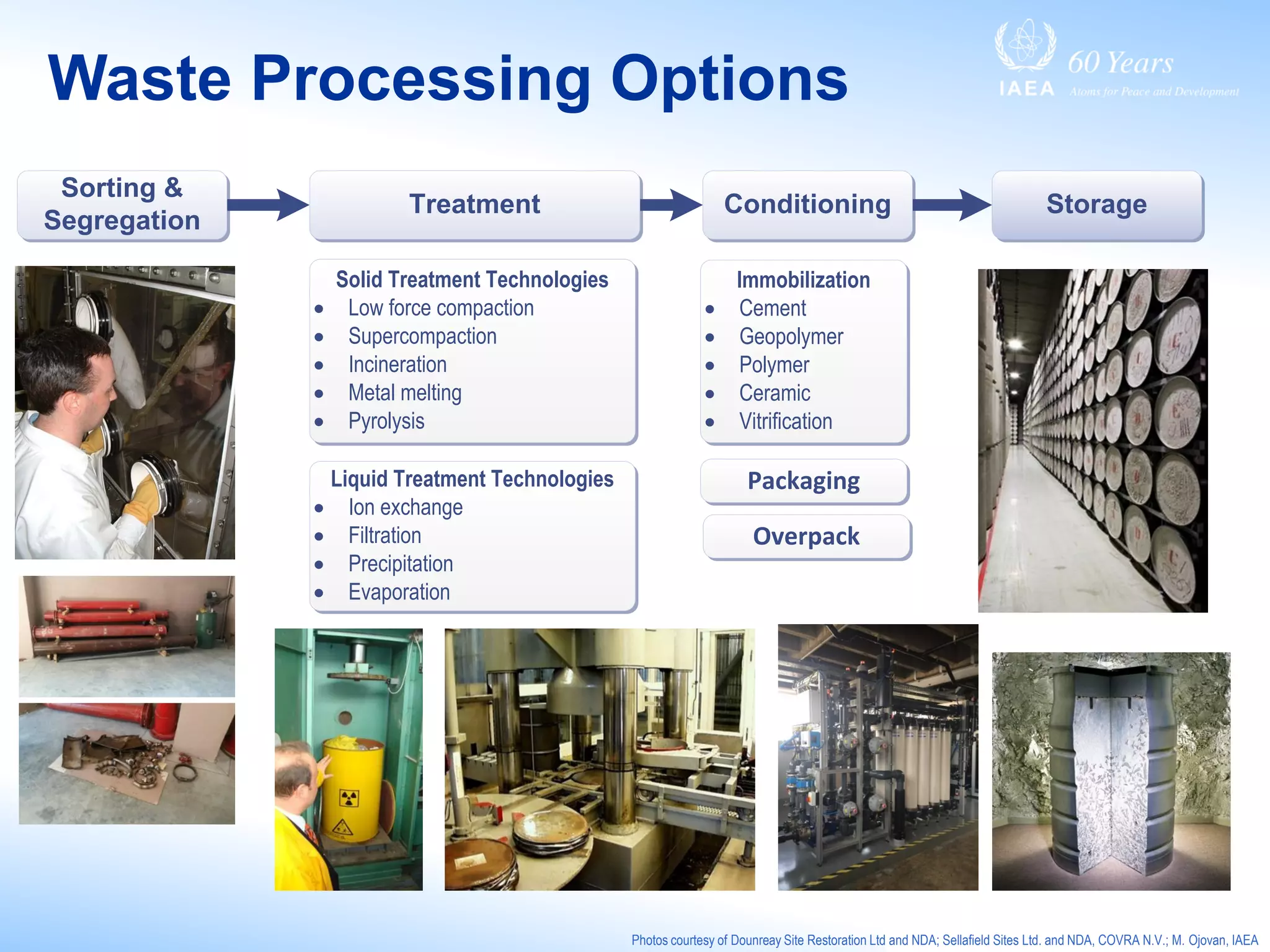

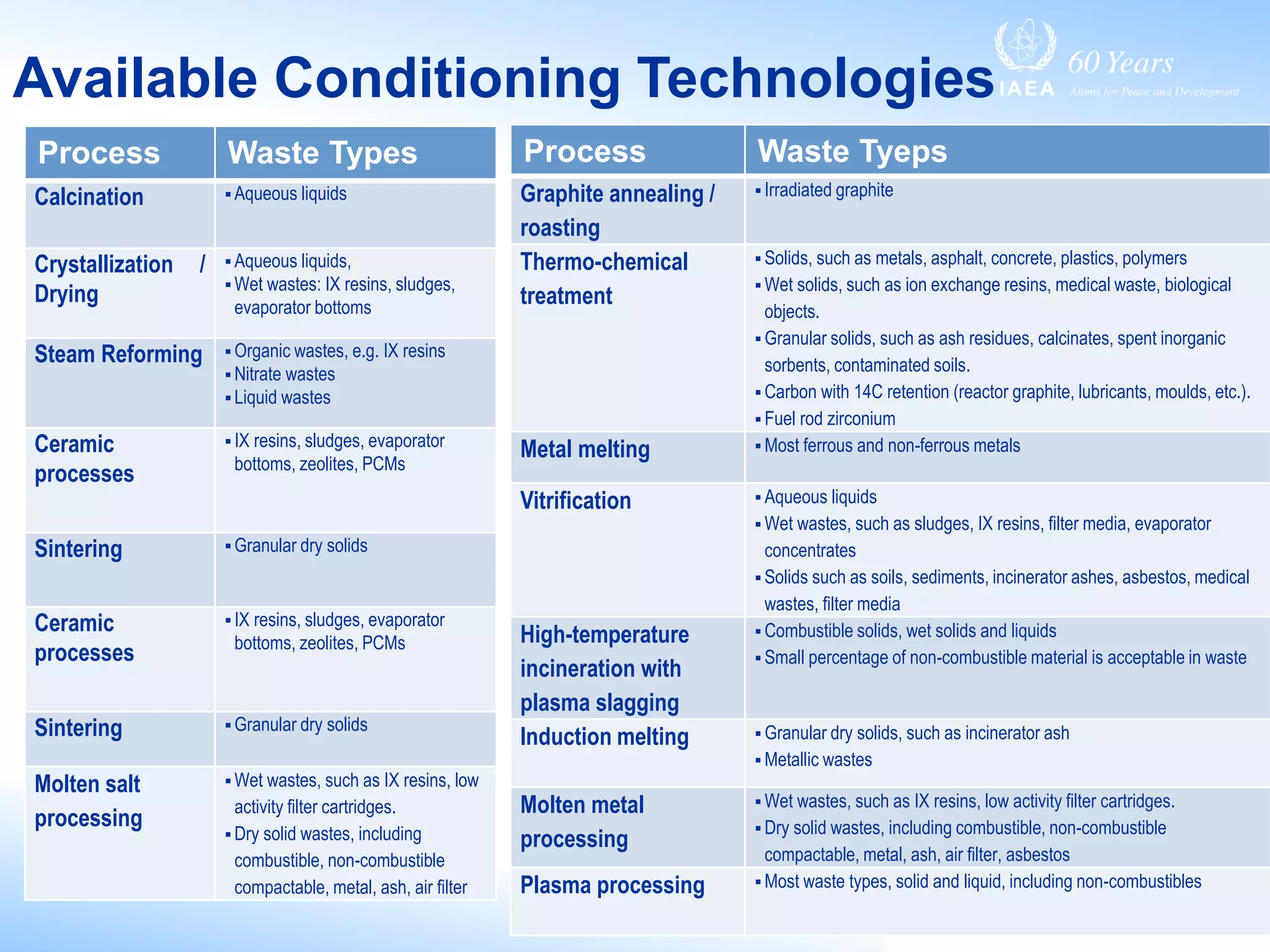

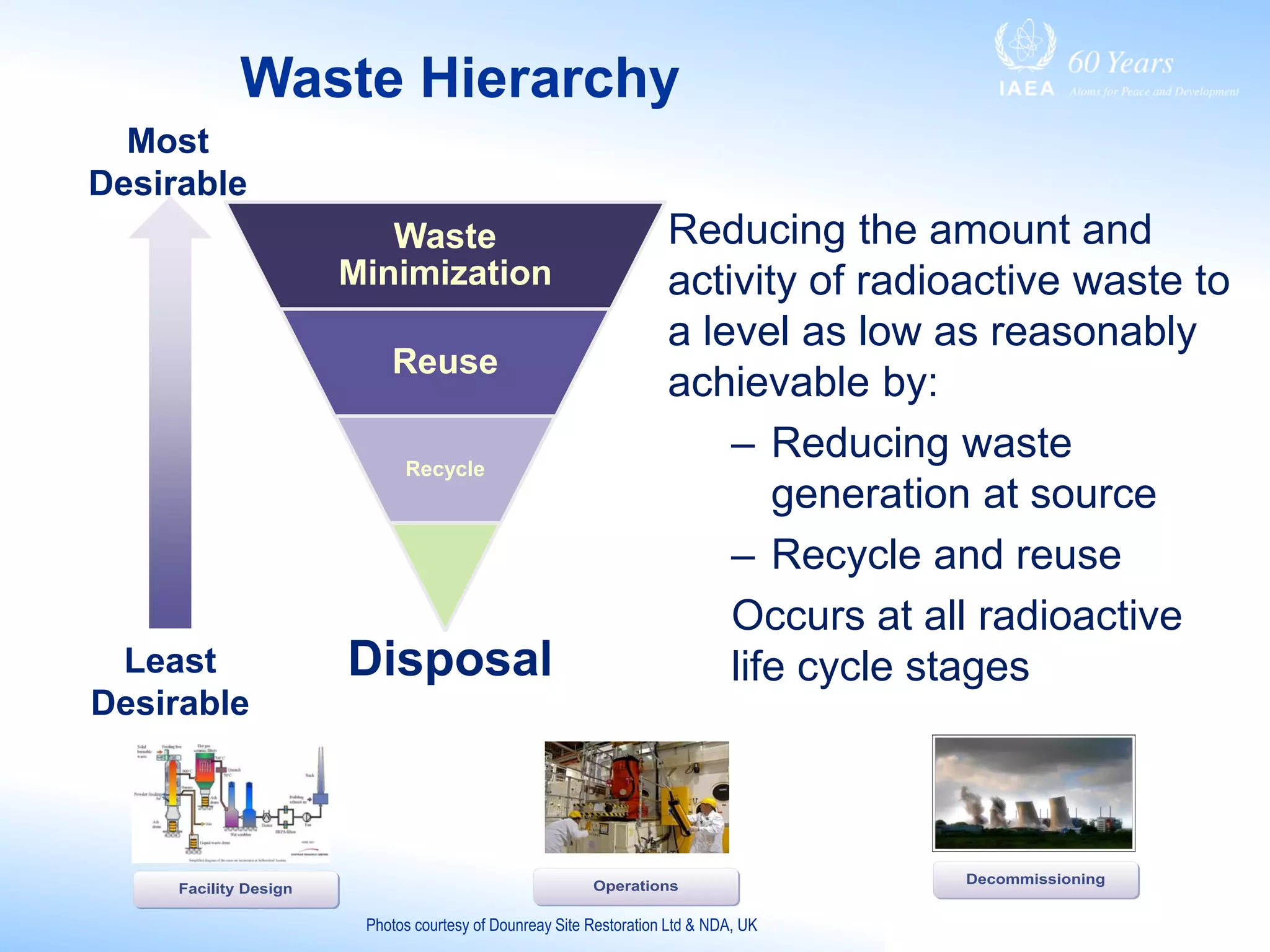

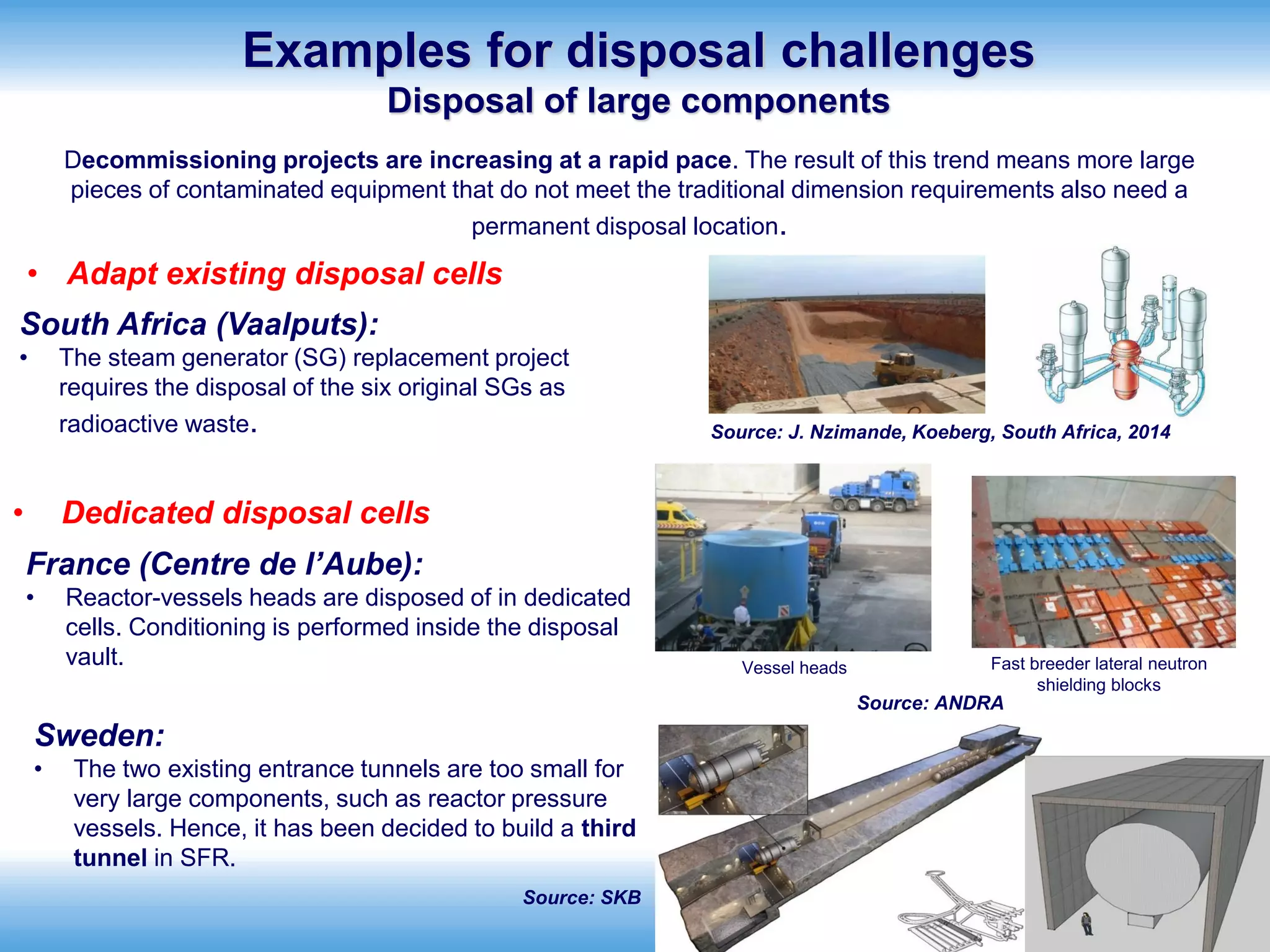

This document discusses problematic low and intermediate level radioactive wastes. It defines problematic waste as waste that does not have readily available methods for safe and economical processing or disposal. Examples of problematic waste streams include spent ion exchange resins, sludges, evaporator concentrates, and aqueous wastes containing organics. The document outlines challenges with predisposal and disposal of problematic waste and discusses available treatment and conditioning technologies. The waste hierarchy of minimizing, reusing, and recycling waste is presented as the most desirable approach.