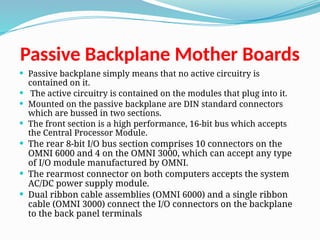

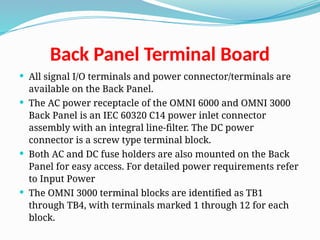

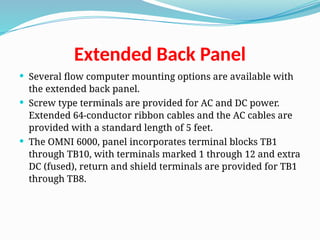

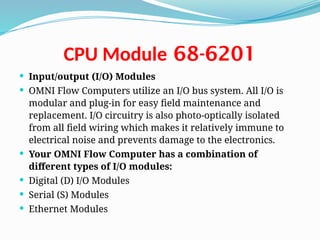

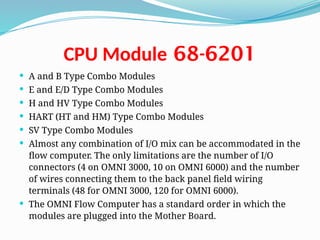

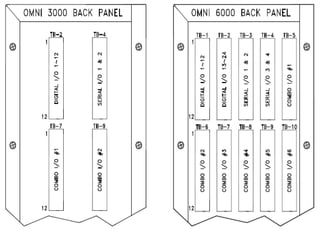

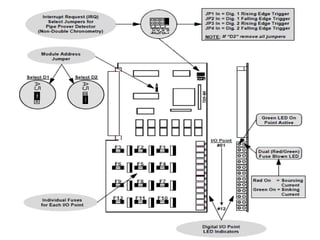

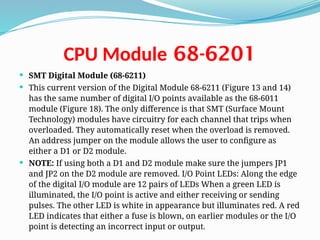

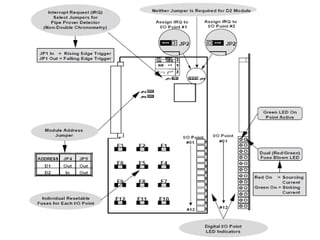

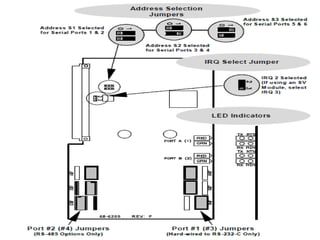

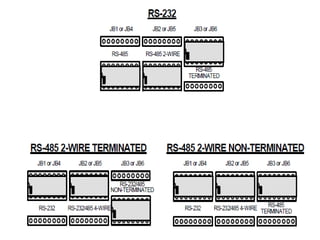

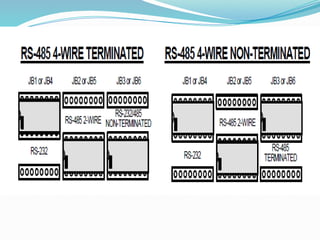

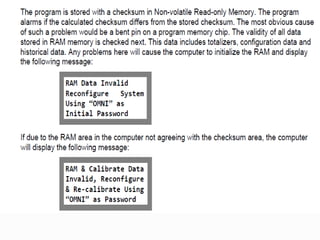

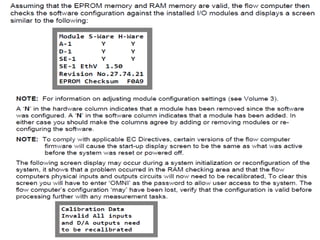

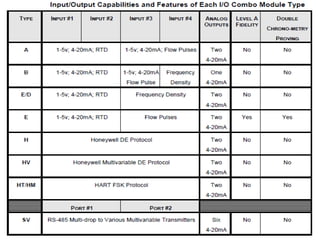

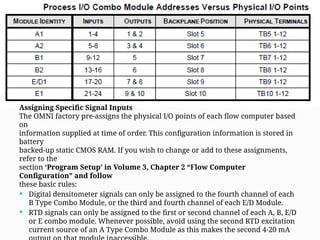

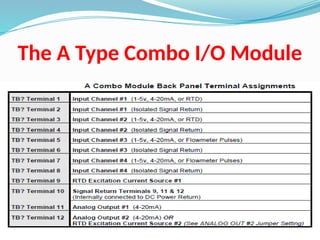

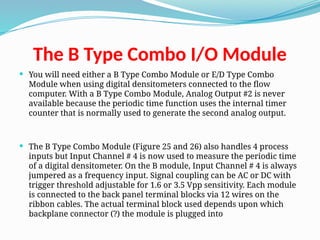

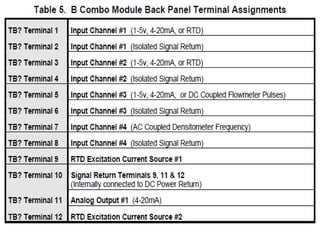

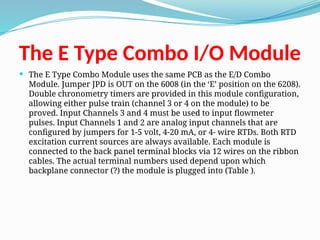

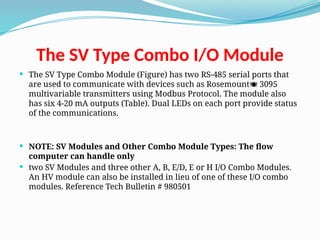

The Omni 3000/6000 flow computers are essential for liquid and gas flow measurement and control, featuring various firmware revisions for different metering systems. The user manual is divided into four volumes covering system architecture, basic operation, advanced configuration, and Modbus addresses, each tailored to specific applications. These flow computers offer modular I/O connectivity, advanced processing capabilities, and robust communication options to support a wide range of applications.