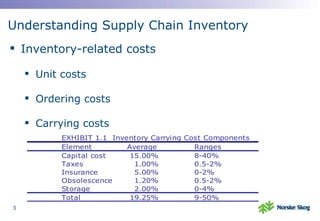

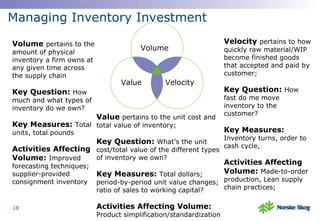

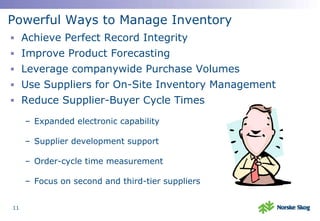

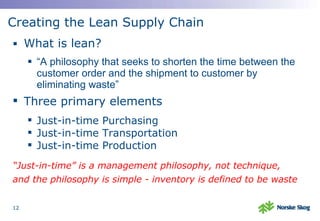

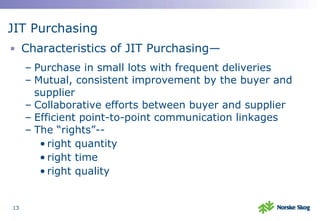

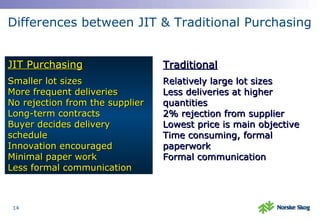

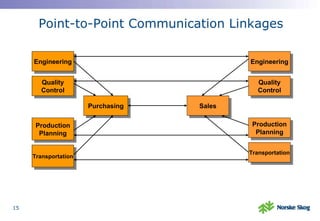

The document discusses inventory management and just-in-time (JIT) practices. It describes different types of inventory including raw materials, work-in-process, and finished goods. It also discusses inventory-related costs and reasons for inventory investment. The document then covers managing inventory through volume, value, and velocity. It provides examples of powerful ways to manage inventory and creating a lean supply chain using JIT purchasing, transportation, and production principles.