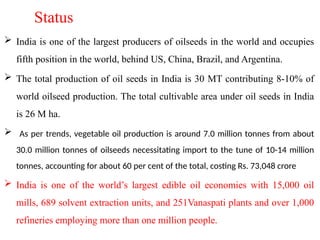

Oil seed milling, also known as oilseed crushing, is the process of extracting oil from seeds like soybeans, sunflower seeds, and rapeseed. This process involves several steps, including seed preparation, oil extraction (often using mechanical pressing or solvent extraction), and oil refining.