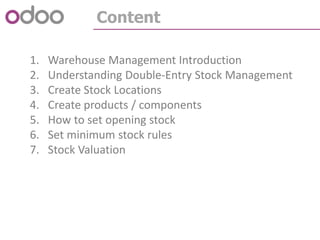

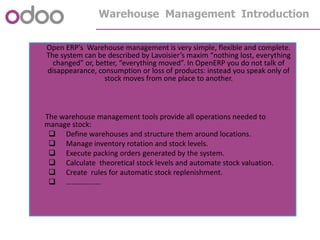

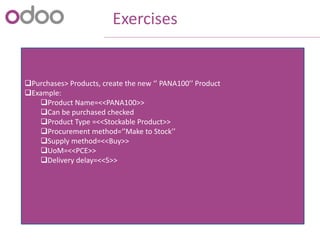

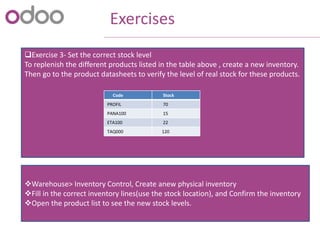

The document provides a comprehensive guide to Odoo's warehouse management system, detailing processes like creating stock locations, managing inventory, and setting minimum stock rules. It includes exercises for practical implementation, such as defining products, stock levels, and chained locations, while emphasizing concepts like double-entry stock management and traceability. Additionally, it covers stock valuation and various modules for enhanced functionalities in warehouse management.