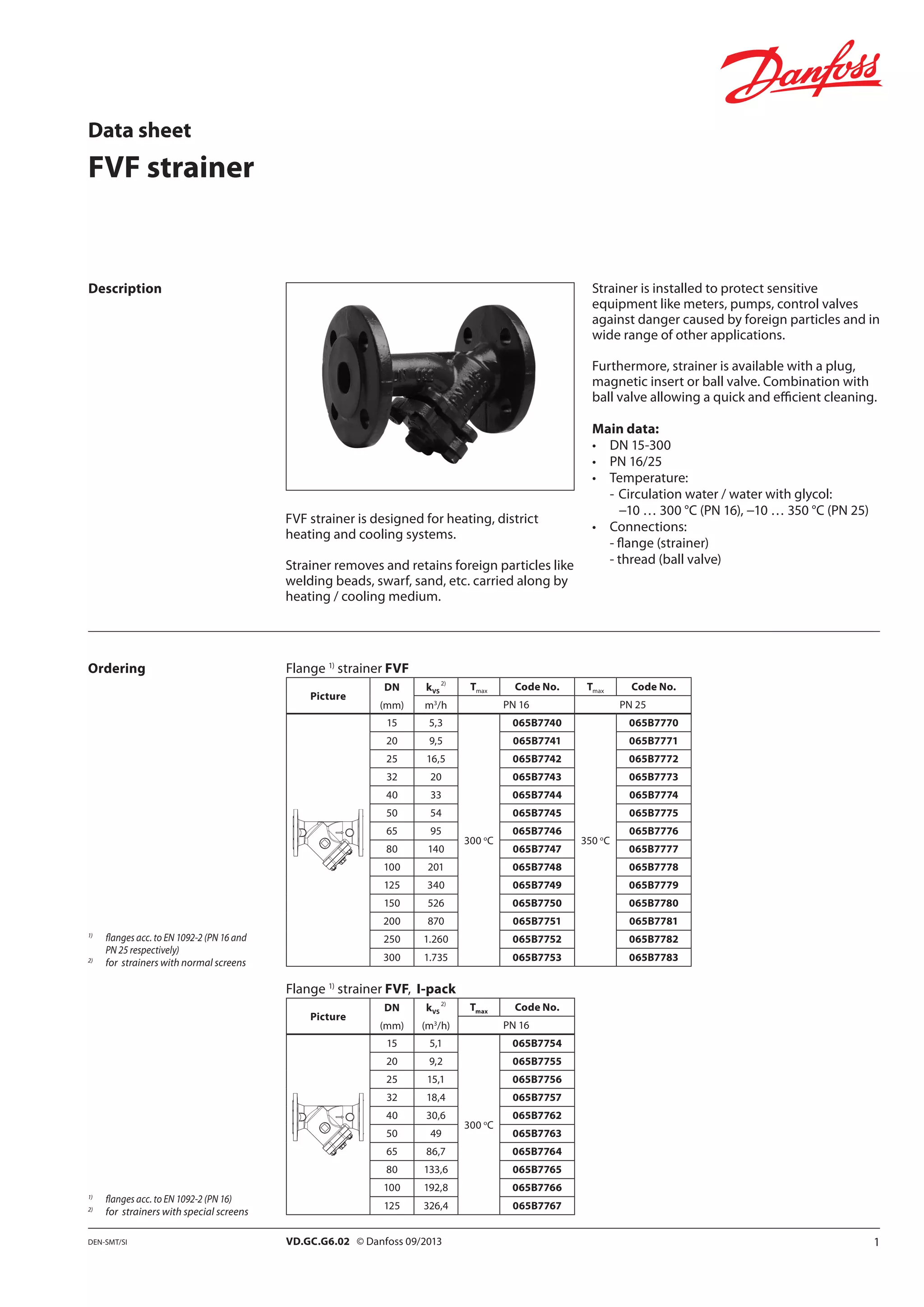

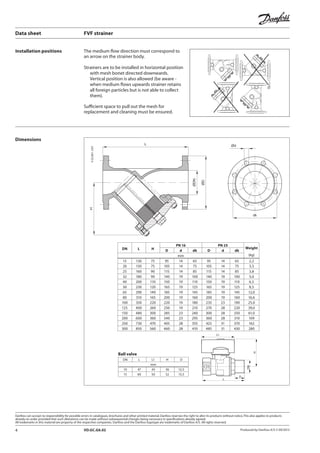

The FVF strainer is designed for heating, district heating and cooling systems to remove foreign particles from liquids. It comes in sizes from 15-300mm and can withstand temperatures from -10 to 300°C. The strainer body is made of cast iron or ductile iron depending on pressure rating and includes a removable screen to catch particles. It can also include accessories like a magnetic insert, ball valve, or different screen mesh sizes.