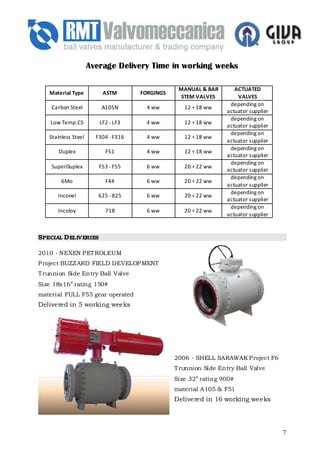

RMT Valvomeccanica is an Italian valve manufacturer located in Solbiate Olona, North of Milan. It was founded in 1998 and merged with another company in 2008. It is part of the GIVA Group, an Italian conglomerate with steel mills and forging capabilities. RMT designs and manufactures ball valves in carbon steel, stainless steel, duplex, super duplex, Inconel, and Incoloy for industries like oil & gas, chemical, and naval. Standard valve components are stocked for quick delivery while customized orders take 6-10 weeks. Production is 150 pieces per month for sizes 12"-20" and 120 pieces for 24"-52".

![TESTING EQUIPMENT

Material Tests (carried out on site):

• MP I - Magnetic P article T est

(MAGISCOP E 3000 silver yoke)

• DYP - Dye P enetrant Examination

• UT - Ultrasonic Test (KRAUT KRAMER)

• P MI - P ositive Material Identification

(Spectrometer NIT ON Analyzer XL2 800)

• Hardness Test

INSTRUMENTS: RMT VM - Test Bench

• Roughness tester MIT UTOYO

• Measuring 3D machine CAM2

• Altimeter TESA

• Comparator MIT UT OYO

• Alesameter MAHR

• Micrometer MIT UTOYO

• X-RAY view box 50000 Cd/mq SEMAT

• T emperature Recorder YOKOGAWA

• Dualscope for painting max 2000 m

FISCHER

RMT VM – Test Bench

Valve Tests

• 2 x Pneumatic & Hydraulic Test

Benches

( ½” to 10”) [one w ith threaded ends]

• 1 x Pneumatic & Hydraulic T est Bench

( 6” to 24” )

• 1 x Pneumatic & Hydraulic T est Bench

( 6” to 36” )

• 1 x Pneumatic & Hydraulic T est Bench

(16” - 48” )

bigger sizes are tested using blind RMT VM – Test Bench

counter flanges

• P ressure gauges max 2000 bar

• Plug T est gauges up to 48”

• T orque verification equipment

ALKITRONIC & Dynamometric

Wrenches max 2000 Nm

• Flow meter ASA for Pneumatic T est

(for metal to metal valves)

• Cryogenic test equipment (bath up to

12” valves)

• Fugitive emission test equipment

(Helium Mass Spectrometer &

Vacuum tester ESA)

• Bunker for valve gas testing up to 36”

600lbs (28” AP I 15000)

RMT VM – Bun ker for Gas Testing

11](https://image.slidesharecdn.com/companyprofile-1283947371431-phpapp01/85/RMT-VMCompany-Profile-11-320.jpg)

![RAW MATERIALS

CARBON STEELS

ASTM A105N

ASTM A350 LF2

ASTM A350 LF3 [-101° IMPACT TESTED]

AISI 4140

F60

STAINLESS STEELS

ASTM A 182 F304

ASTM A 182 F6

ASTM A 182 F316

ASTM A 182 F317

ASTM A 182 F316L

ASTM A 182 F316TI

ASTM A 182 F316LN

ASTM A 182 F321

ASTM A 182 F347

A564 GR. 630

(UNS S17400), 17-4-PH

A479 XM19 (NITRONIC 50)

DUPLEX STAINLESS STEELS

ASTM A 182 F51 (UNS S31803)

SUPER DUPLEX STAINLESS STEELS

ASTM A 182 F53 (UNS S32750)

ASTM A 182 F55 (UNS S39276)

6 MO

ASTM A 182 F44

(UNS S31254)

NICKEL ALLOYS

INCOLOY 825 (UNS N8825)

INCOLOY 625 (UNS N6625)

INCONEL 718

(UNS N07718 B637 GR718)

INCONEL X 750

(UNS S07750 B637 GR688)

14](https://image.slidesharecdn.com/companyprofile-1283947371431-phpapp01/85/RMT-VMCompany-Profile-14-320.jpg)