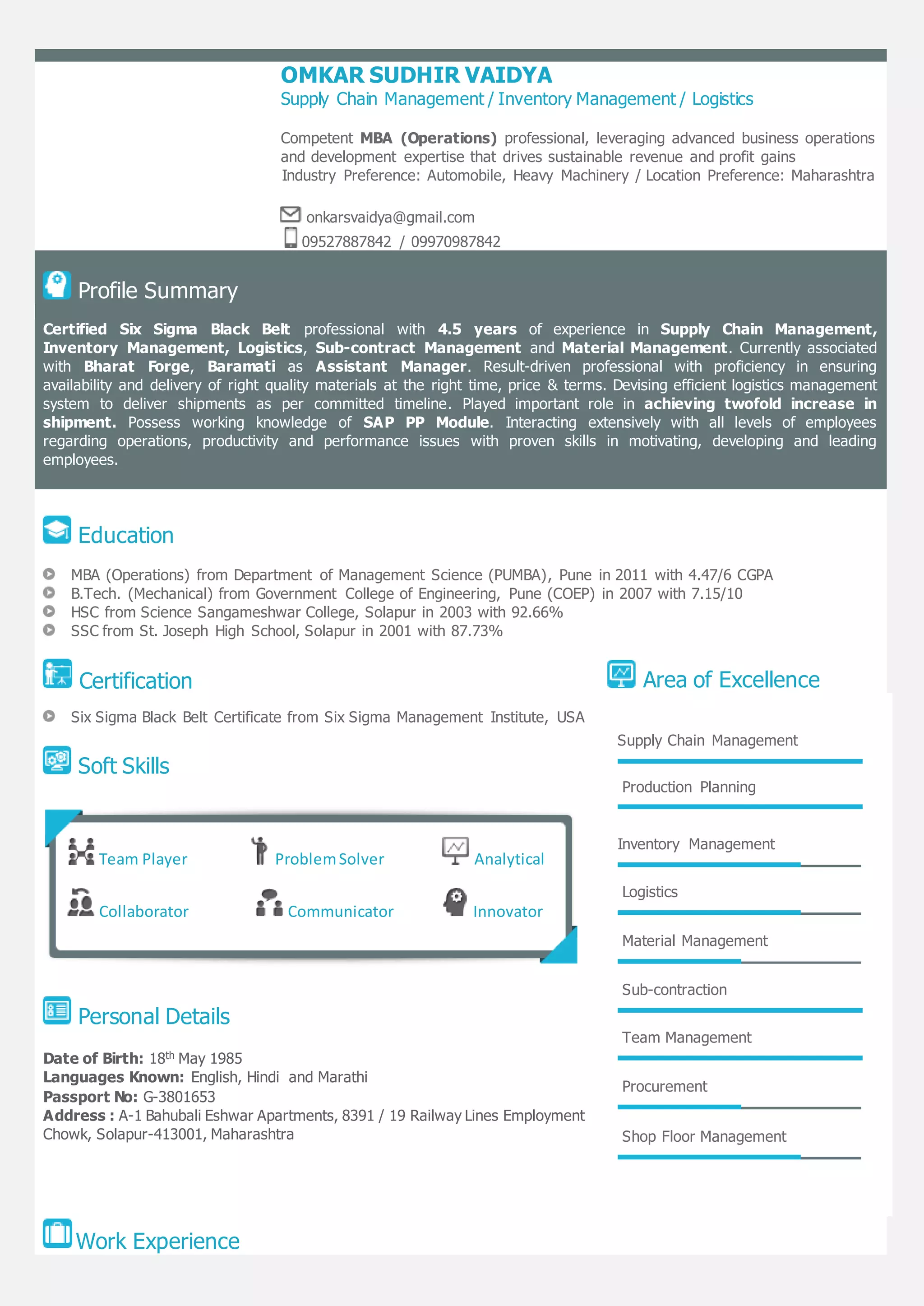

Omkar Sudhir Vaidya has over 4.5 years of experience in supply chain management, inventory management, logistics, and material management. He is currently an Assistant Manager at Bharat Forge in Baramati, Maharashtra. He has a MBA in Operations and a B.Tech in Mechanical Engineering. He is a Six Sigma Black Belt and is proficient in ensuring the availability and delivery of materials on time. He has played an important role in achieving a twofold increase in shipments.