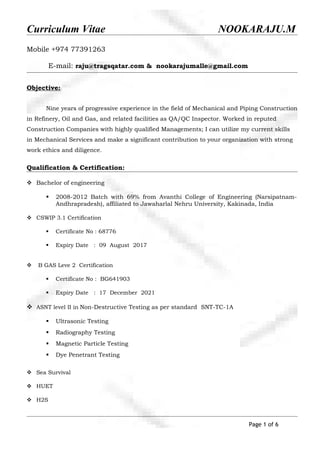

Nookaraju M has over 9 years of experience in mechanical and piping construction in oil, gas, and related facilities as a QA/QC inspector. He holds a Bachelor's degree in engineering and various certifications including CSWIP 3.1, B GAS Level 2, and ASNT level II in non-destructive testing. His work experience includes projects in Qatar and Malaysia for companies such as Qatar Petrochemical Company, Ras Laffan Olefins Company, Hyundai, and Qatar Vinyl Company, where he served as a welding inspector responsible for tasks like welding procedure qualification, inspection, and non-destructive testing.