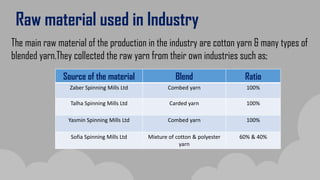

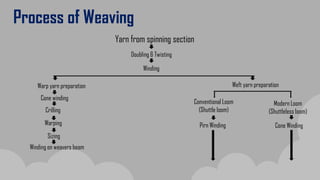

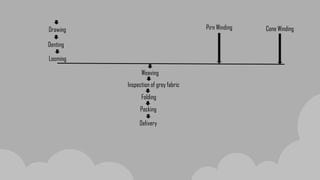

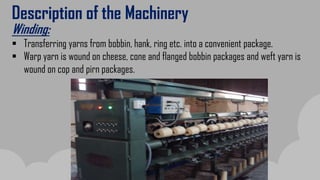

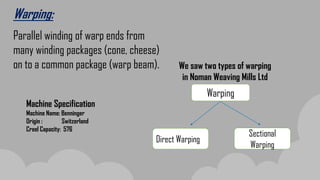

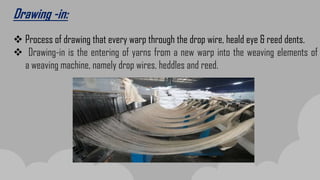

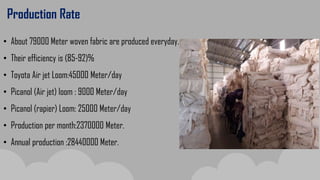

The document summarizes a student group's presentation on their industrial visit to Noman Weaving Mills Ltd. It provides details on the company's background, production processes, machinery used, quality control procedures, production rates, and utilities. The visit aimed to help students bridge theory with practice and gain exposure to the textiles industry. The group thanked attendees for listening to the presentation summarizing their site visit.