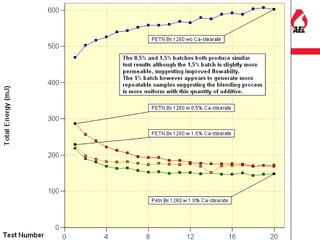

The document provides information on PETN (pentaerythritol tetranitrate) properties and its use in an automated detonator manufacturing plant. It discusses PETN's chemical formula, manufacturing processes, parameters for dosing and pressing trials at the plant. Results from particle size analysis using a Mastersizer and powder flow testing using an FT4 rheometer are also summarized. The FT4 tests evaluated PETN batch stability and permeability to determine how well the powder would flow and compress for detonator filling.

![CONTENTS

• INTRODUCTION

• PROPERTIES

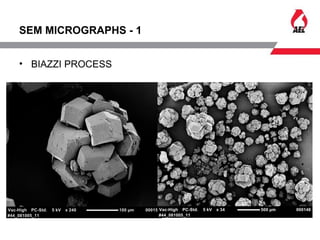

• MANUFACTURE

– Biazzi Process

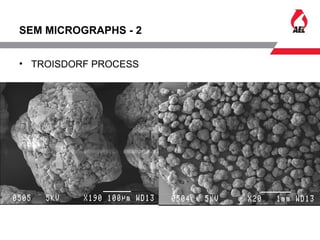

– Troisdorf Process

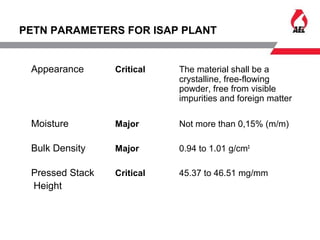

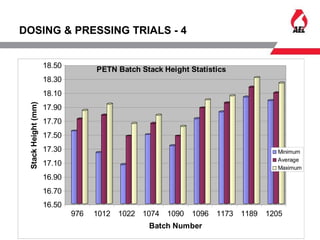

• PETN PARAMETERS for ISAP PLANT

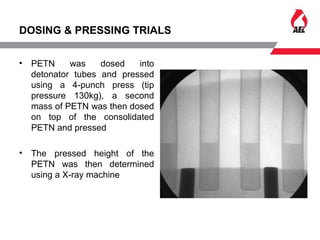

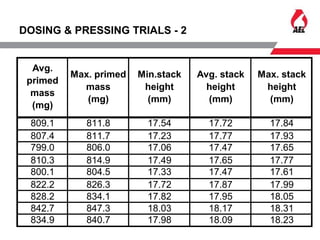

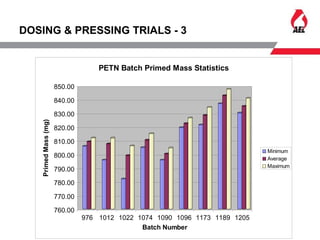

• DOSING & PRESSING TRIALS

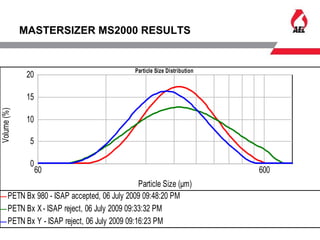

• MASTERSIZER MS2000 RESULTS

• FT4 – POWDER RHEOMETER

• FT4 RESULTS

- Stability [REP] Test

- Permeability Test](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-2-320.jpg)

![INTRODUCTION

• Pentaerythritol-tetranitrate [PETN] first mentioned in a

German patent issued in 1894

• Manufacture of PETN and Cordtex detonating fuse was

started at the Somerset West Factory early in 1953

• In 1959 packing of PETN for use in detonator manufacture at

Modderfontein was begun

• Construction of PETN plant at Modderfontein commenced in

April 1967 and completed in April 1968](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-3-320.jpg)

![PROPERTIES

• Chemical formula – C5H8N4O12

• Molecular mass – 316.15 a.m.u

• Forms colorless prismatic crystals that together appear white

and opaque

• Density TMD: 1.78 g/cm3

Nominal: 1.76 g/cm3

• Melting Point [pure]: 141 – 142 °C

• Critical Temperature: 192 °C

• Velocity of Detonation: 7.975 km/s @ ρ=1.67 g/cm3

Detonation Pressure ρ=1.77 ρ=1.67 ρ=0.99 g/cm3

Measured 33.5 30.0 8.7 GPa

Calculated 33.2 28.0 10.0 GPa](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-4-320.jpg)

![VIDEO

• Johannesburg to Cape Town – 1393 km @ 6.5 km/s

There and back: approx 7 minutes

• HMX – Velocity of Detonation: 9.11 km/s @ ρ=1.89g/cm3

- Detonation Pressure [GPa] ρ=1.900g/cm3

Measured 39.0 GPa

• Pdet = 0.25xρ0xVOD2

Shock tube](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-5-320.jpg)

![DOSING & PRESSING TRIALS - 5

PETN Batch Comparison

17

17.2

17.4

17.6

17.8

18

18.2

18.4

780 790 800 810 820 830 840 850

PETN mass (mg)

PressedStackHeight(mm)

PETN Bx 976 [det grade] PD = 1.001g/cc PETN Bx1012 [det grade] PD = 0.999g/cc PETN Bx1022 [det grade] PD = 0.989g/cc

PETN Bx 1074 [det grade] PD = 1.003g/cc PETN Bx 1090 [det grade] PD = 0.990g/cc PETN Bx 1205 [det grade] PD = 1.033g/cc

PETN Bx 1096 [det grade] PD = 1.017g/cc PETN Bx 1173 [det grade] PD = 1.025g/cc PETN Bx 1189 [det grade] PD = 1.043g/cc](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-14-320.jpg)

![FT4 – POWDER RHEOMETER [2]

• FT4 Principle of Operation

Blade rotates and moves down and up through powder at a

defined helix angle and speed

• Measured Parameters are: -

Torque

Force

Height](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-17-320.jpg)

![FT4 – POWDER RHEOMETER [3]](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-18-320.jpg)

![FT4 – POWDER RHEOMETER [4]

CONDITIONING

Variation in the packing state of the powder will significantly change the flow

properties.

It is essential to prepare the sample before the test by Conditioning.

The Conditioning process involves gentle displacement of the whole powder

sample in order to loosen and slightly aerate the powder into an homogenised

state.

Powder that is consolidated during filling will flow differently to one that was

filled gently, possibly trapping air.](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-19-320.jpg)

![FT4 – POWDER RHEOMETER [5]](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-20-320.jpg)

![FT4 – POWDER RHEOMETER [6]](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-21-320.jpg)

![FT4 – POWDER RHEOMETER [7]](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-22-320.jpg)

![FT4 – POWDER RHEOMETER [8]](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-23-320.jpg)

![FT4 – POWDER RHEOMETER [9]](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-24-320.jpg)

![FT4 – POWDER RHEOMETER [10]](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-25-320.jpg)

![FT4 – POWDER RHEOMETER [11]](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-26-320.jpg)

![FT4 – POWDER RHEOMETER [12]](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-27-320.jpg)

![FT4 – POWDER RHEOMETER [13]](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-28-320.jpg)

![FT4 – POWDER RHEOMETER [14]](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-29-320.jpg)

![FT4 RESULTS

Stability [REP] Test

• The standard Stability Test is a combination of Conditioning

and Test cycles, designed to assess if the powder is going to

change as a result of being made to flow. Therefore, unlike

other test programs, this test does not intentionally introduce

a variable, such as flow rate or air velocity. Hence, any

change in the flow energy during the test has to be a result of

the powder flow properties changing.](https://image.slidesharecdn.com/9b2bb842-8dbb-4e6b-a36a-78462f20d828-160708055557/85/NIXT-Presentation-23-July-2009-30-320.jpg)