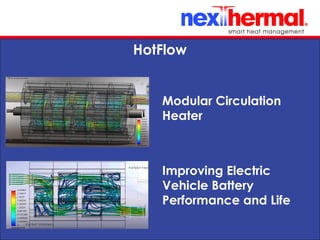

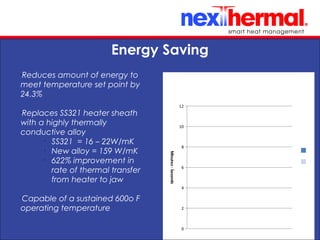

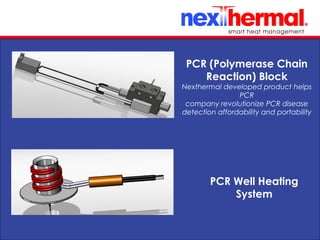

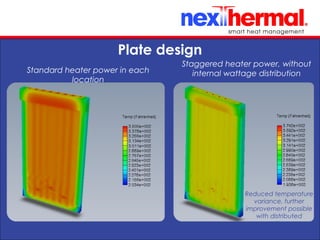

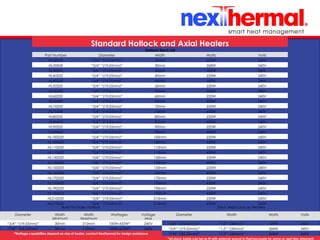

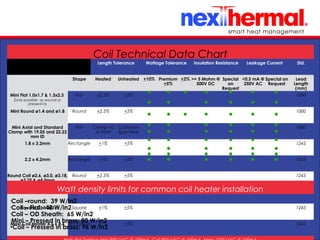

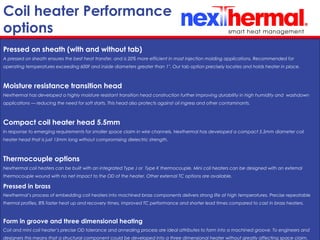

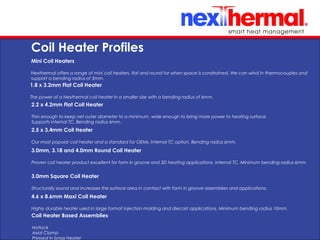

Nexthermal, formerly known as Hotset Corporation, is transitioning to offer a wider range of heating solutions including heating elements and control systems, emphasizing their commitment to smart heat management. The company aims to enhance process heating applications through innovative and efficient heating technologies, backed by their international presence and customer-focused approach. Their products are designed for diverse industries, including electric vehicle systems and medical devices, showcasing flexibility, durability, and improved thermal performance.