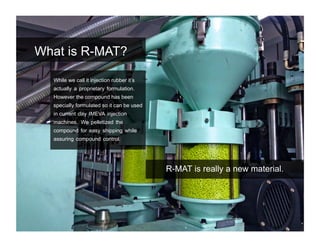

R-mat is a new proprietary cushioning material designed to outperform EVA in the footwear industry, offering superior energy return, traction, and durability. It can be used across various applications, including sock liners, midsoles, and outsoles, while integrating easily into existing production processes. Transitioning to R-mat promises better quality products and potential increases in sales and market share for manufacturers.