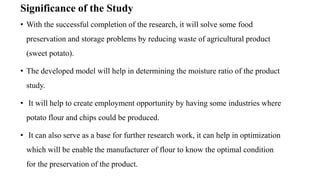

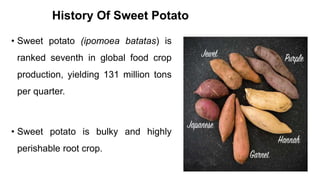

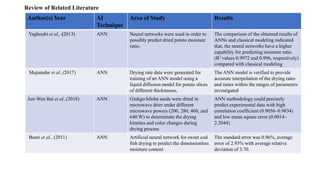

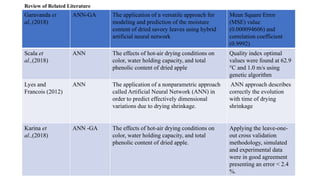

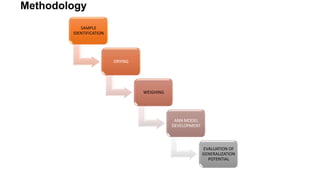

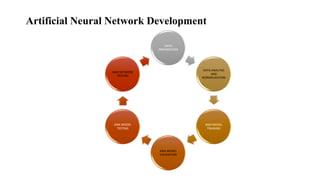

The document outlines a study aimed at predicting drying parameters for sweet potatoes using an artificial neural network (ANN) model. It discusses the significance of reducing moisture content for food preservation and highlights the study's objectives, including the characterization of sweet potatoes and the development of a mathematical model for drying kinetics. By addressing these issues, the research aims to improve storage methods and contribute to food security and employment opportunities in potato processing.