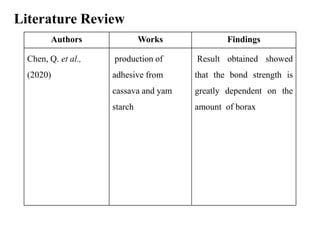

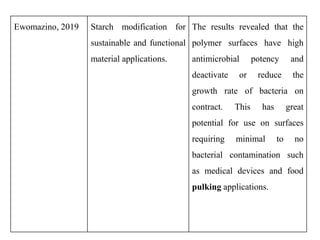

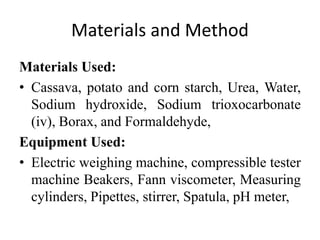

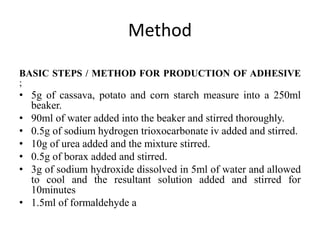

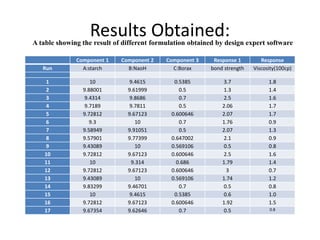

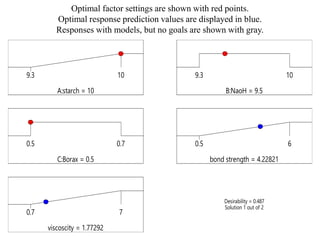

This document outlines the optimization of thermally modified starch adhesives derived from cassava, potato, and corn starch, emphasizing their potential as biodegradable alternatives to petroleum-based plastics. It details the study's objectives, methodology, results on bond strength and viscosity, and concludes with recommendations for improving adhesive properties and applications. The findings highlight the importance of using borax and other additives for enhancing adhesive performance while suggesting further exploration into extending shelf life and diverse applications.