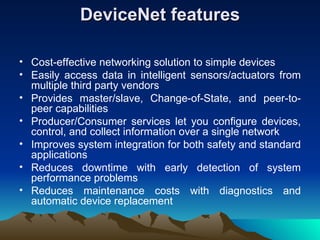

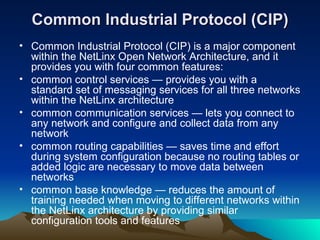

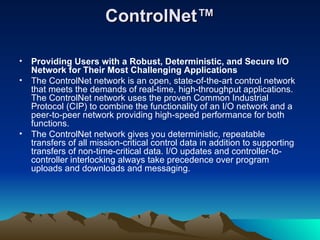

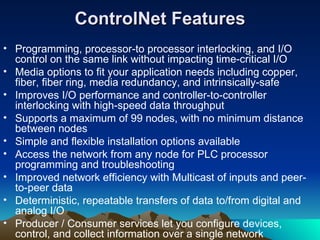

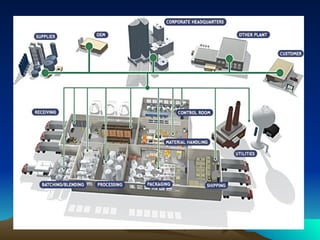

NetLinx Open Network Architecture uses DeviceNet, ControlNet, and EtherNet/IP networks which all speak a common language called CIP. This integrated architecture seamlessly connects devices, machines, and business systems. DH-485 is a local area network for factory devices with a maximum length of 4000 feet and transmission rate of 19.2 kbit/s. DeviceNet provides connections between simple devices like sensors and controllers using CIP. Common Industrial Protocol is the common language that provides control, configuration and data collection across the different networks.