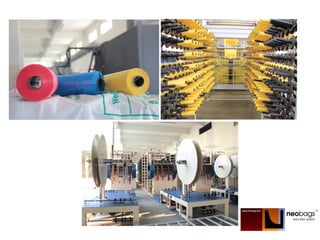

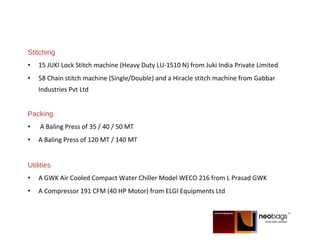

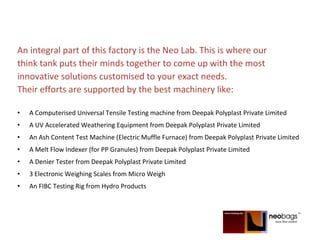

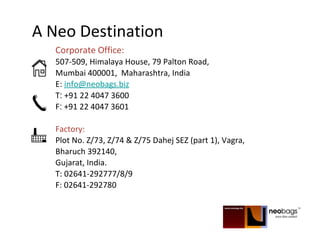

Neobags is an Indian bulk container company that has established a "Neo way" of working based on principles of innovation, customization, partnership, and service. The company prides itself on delivering customized bag solutions and operates a large, modern factory equipped with advanced machinery to produce a wide range of bag types. The factory emphasizes quality standards and employee welfare through various initiatives.