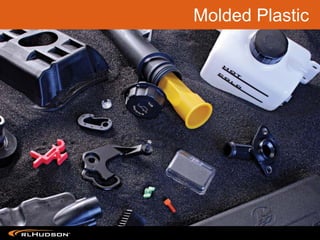

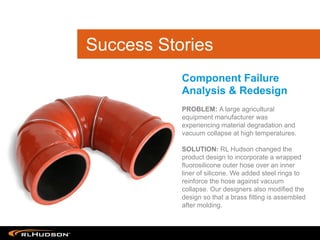

RL Hudson is a manufacturer of molded rubber, plastic, and polyurethane products headquartered in Oklahoma that was founded in 1980. It employs over 70 people and offers advantages to customers in five key areas: product design and engineering, material technology, quality assurance, supply chain management, and a wide product range. It provides services from product design through material selection, development, and finished product testing.