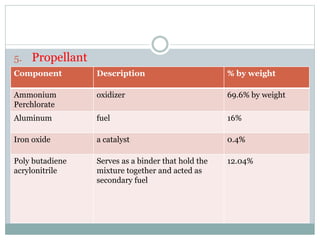

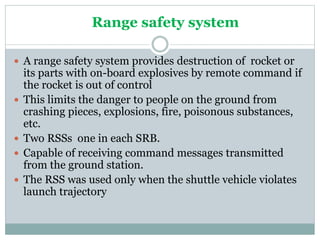

The Space Launch System uses two solid rocket boosters that provide most of the thrust during launch. Each booster contains propellant made of ammonium perchlorate, aluminum, and binders that ignite and burn for 124 seconds. The boosters are jettisoned at an altitude of 45 km after which parachutes deploy to slow their descent into the ocean for recovery. A range safety system can destroy the boosters by remote command if needed for safety.