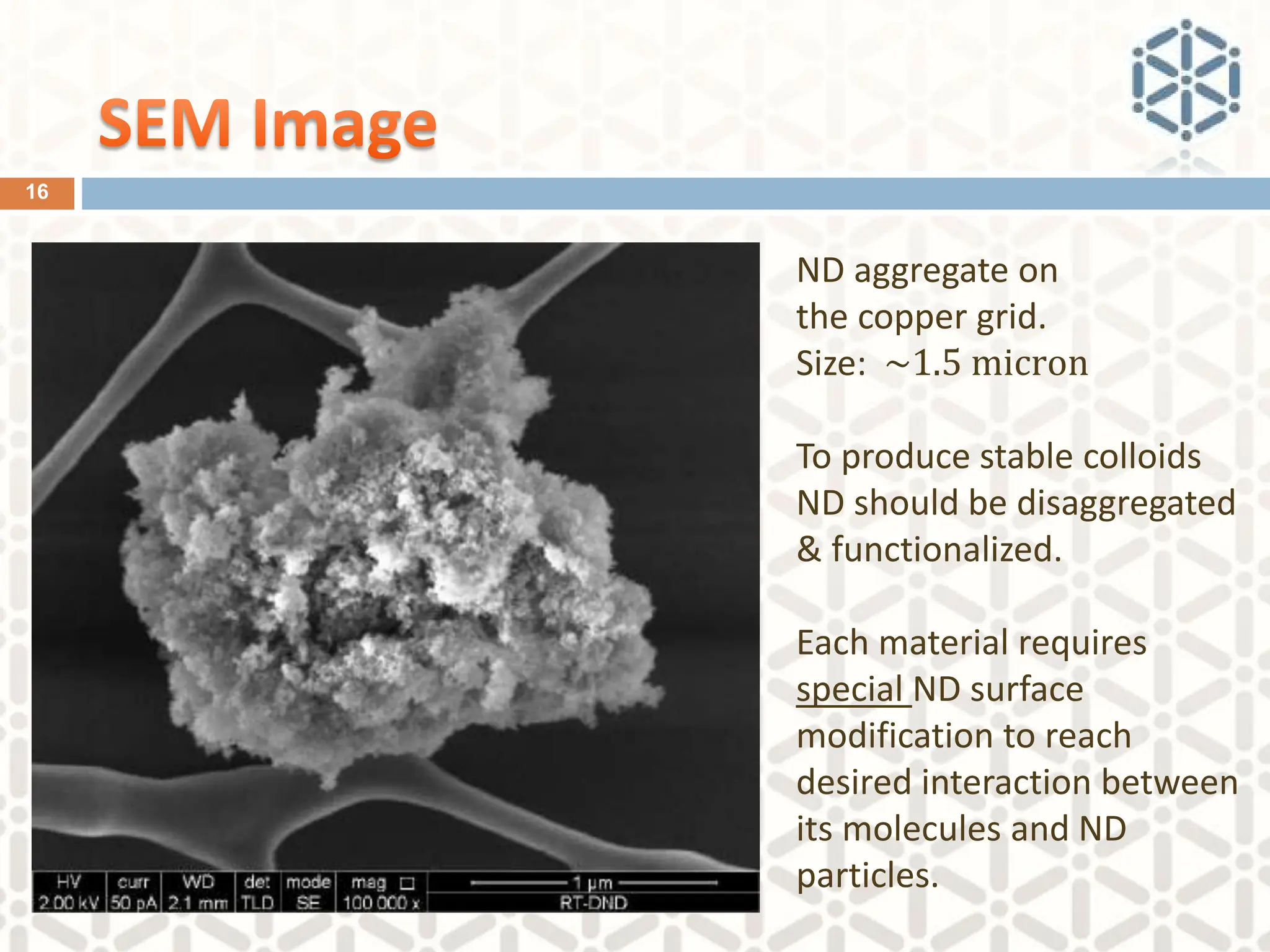

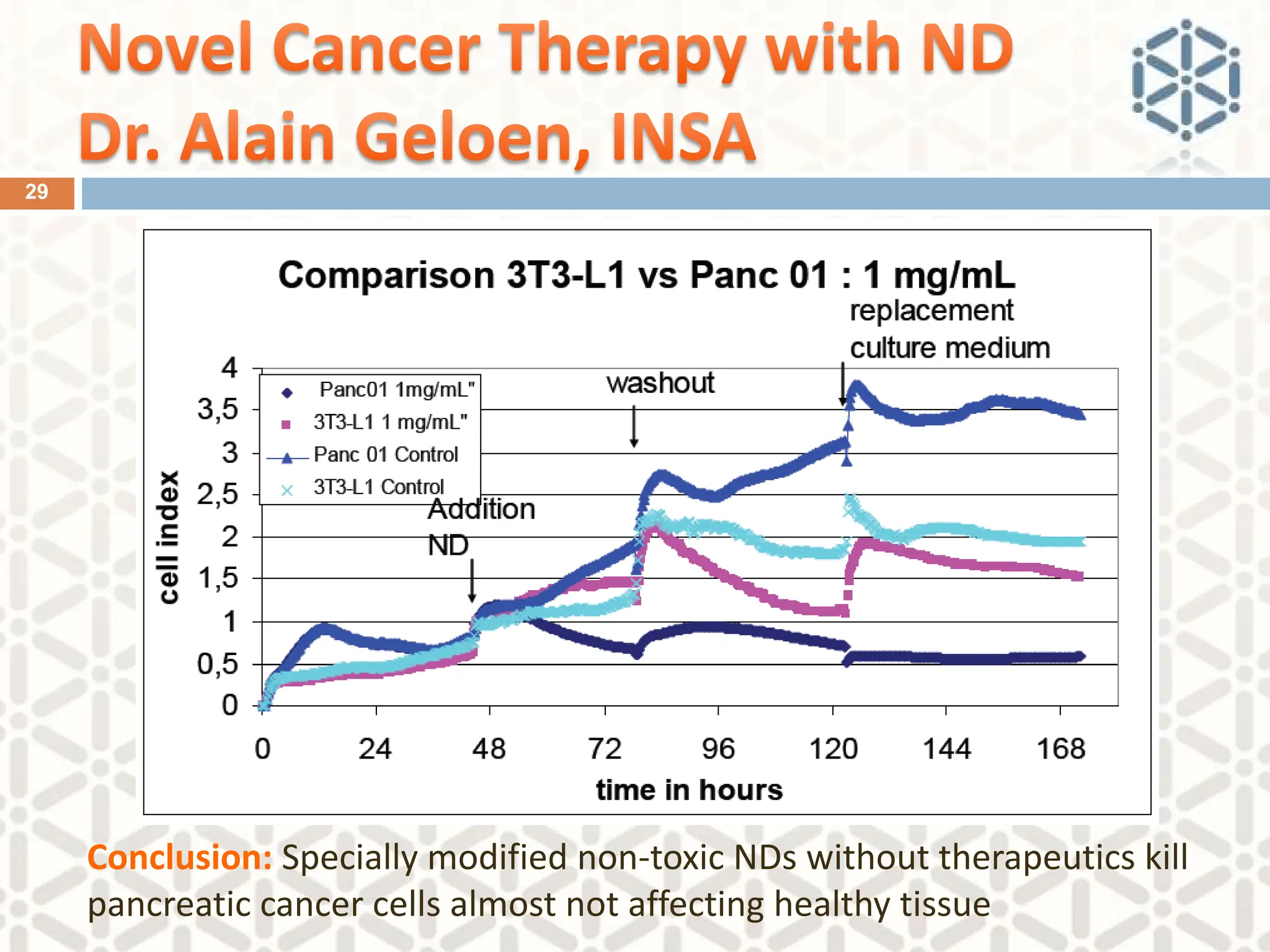

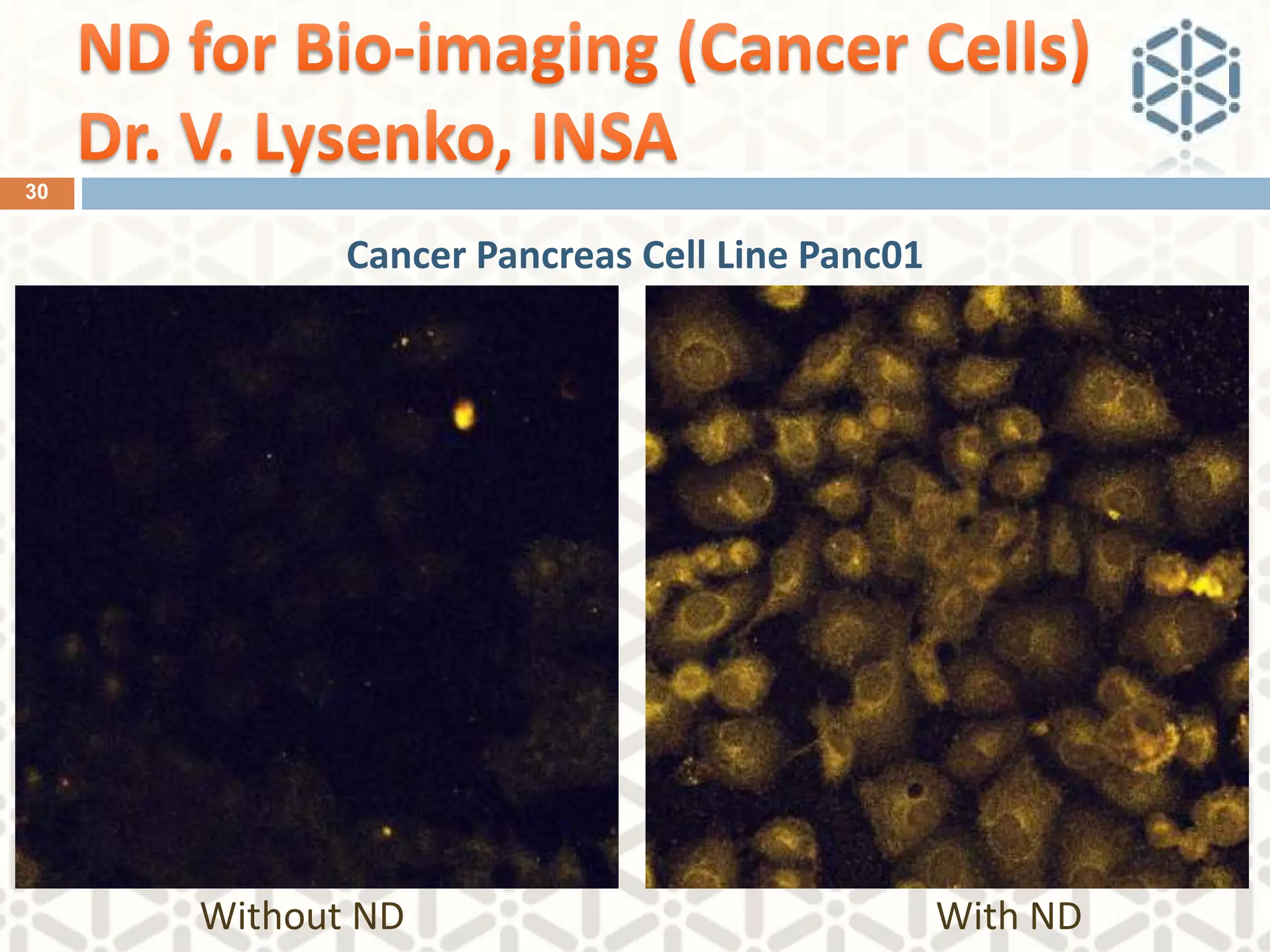

Ray Techniques Ltd., established in 2009 in Israel, specializes in nanodiamond (nd) technologies, focusing on the synthesis, modification, and application of high-quality nanodiamonds for diverse industrial uses. The company aims to address challenges related to the quality and cost of nd products while developing innovative applications in fields such as biomedicine, energy storage, and advanced materials. Their proprietary laser synthesis technology enables the production of uniform and customizable nanodiamond additives and is supported by a series of patents and ongoing R&D projects.