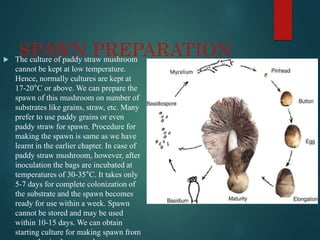

Volvariella volvacea, commonly known as paddy straw mushroom, is cultivated in parts of India with annual production around 15,000 tons. It grows well in temperatures between 30-38°C and 80-90% humidity. Spawn is prepared by inoculating substrates like paddy grains or straw and incubating at 30-35°C until fully colonized in 5-7 days. Conventionally, it is cultivated outdoors under trees by soaking and inoculating bundles of paddy straw, with a biological efficiency of 10%. Indoor cultivation in insulated rooms yields higher, involving composting cotton waste substrate for 4 days, pasteurization at 60-62°C, spawning at