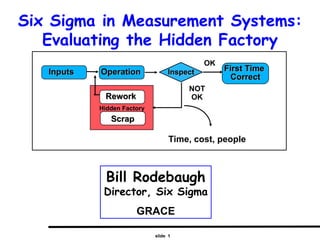

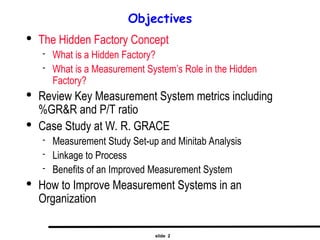

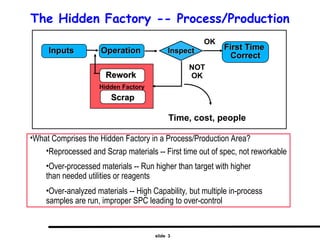

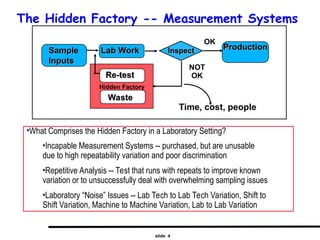

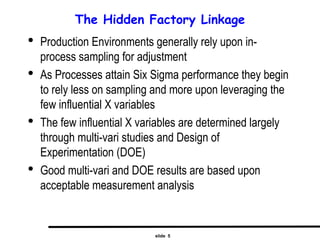

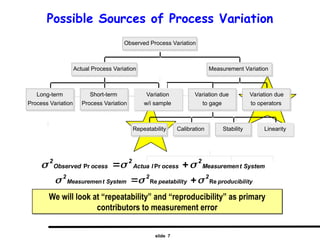

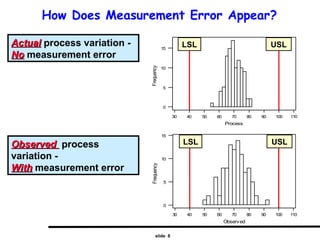

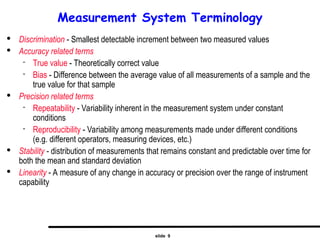

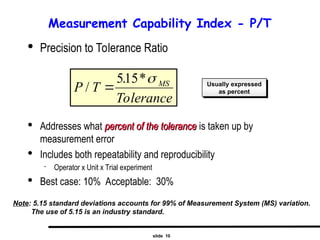

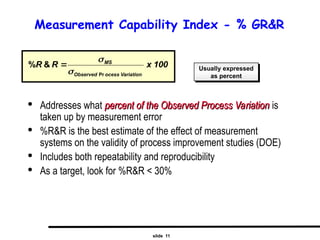

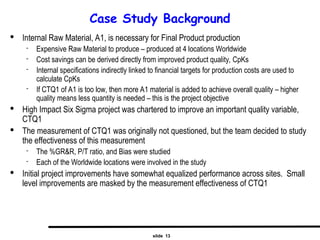

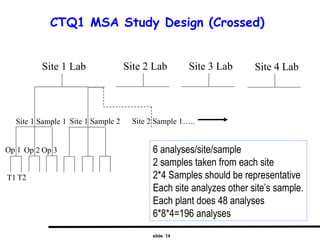

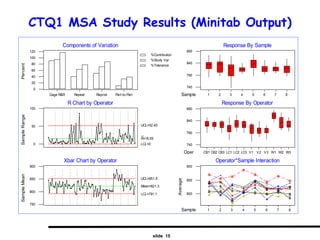

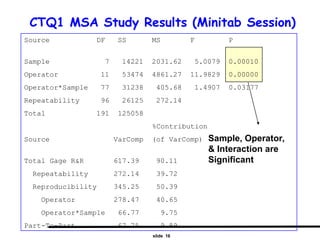

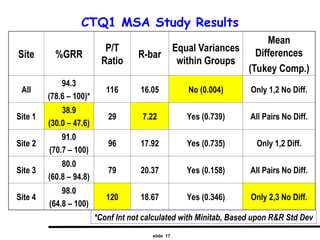

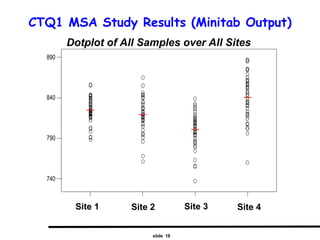

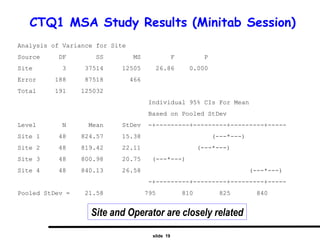

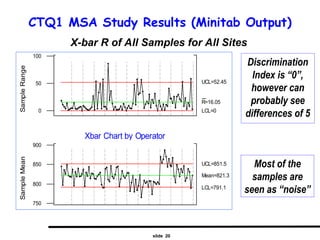

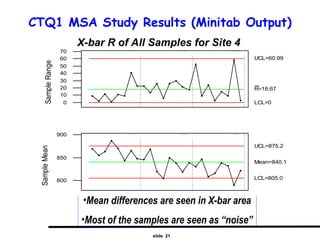

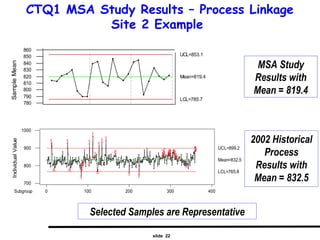

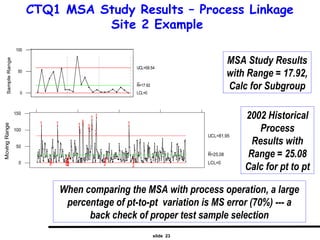

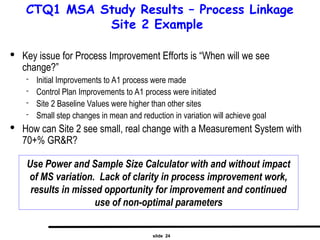

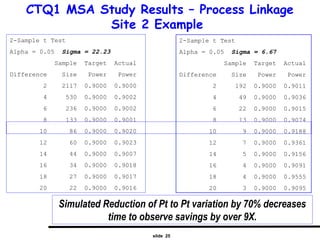

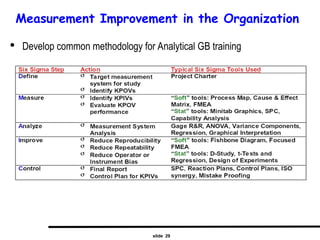

The document discusses the concept of the 'hidden factory' in measurement systems, emphasizing its implications for process efficiency and quality. It reviews essential measurement metrics such as %gr&r and p/t ratio, and includes a case study from W. R. Grace that highlights measurement effectiveness and its link to process improvement. The study reveals sources of measurement error and outlines strategies for enhancing measurement systems within organizations.