MQP Poster Draft 4.20.15final

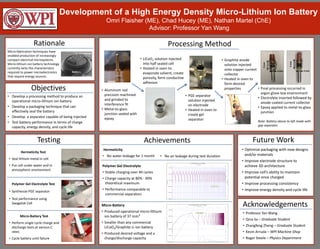

- 1. Development of a High Energy Density Micro-Lithium Ion Battery Omri Flaisher (ME), Chad Hucey (ME), Nathan Martel (ChE) Advisor: Professor Yan Wang Rationale Testing Processing Method Achievements Future Work Micro-fabrication techniques have enabled production of increasingly compact electrical microsystems. Micro-lithium ion battery technology currently lacks the characteristics required to power microelectronics that require energy sources. Hermeticity Test • Seal lithium metal in cell • Put cell under water and in atmospheric environment • Aluminum rod precision machined and grinded to interference fit • Metal-to-glass junction sealed with epoxy • Optimize packaging with new designs and/or materials • Improve electrode structure to achieve 3D architecture • Improve cell’s ability to maintain potential once charged • Improve processing consistency • Improve energy density and cycle life Objectives • Develop a processing method to produce an operational micro-lithium ion battery • Develop a packaging technique that can effectively seal the battery • Develop a separator capable of being injected • Test battery performance in terms of charge capacity, energy density, and cycle life Acknowledgements Polymer Gel Electrolyte • Stable charging over 40 cycles • Charge capacity at 80% - 90% theoretical maximum • Performance comparable to commercial separators • Professor Yan Wang • Qina Sa – Graduate Student • Zhangfeng Zheng – Graduate Student • Kevin Arruda – WPI Machine Shop • Roger Steele – Physics Department Polymer Gel Electrolyte Test • Synthesize PGE separator • Test performance using Swagelok Cell Micro-Battery Test • Perform single cycle charge and discharge tests at various C rates • Cycle battery until failure Micro-Battery • Produced operational micro-lithium ion battery of 37 mm3 • Smaller than any commercial LiCoO2/Graphite Li-ion battery • Produced desired voltage and a charge/discharge capacity Hermeticity • No water leakage for 1 month • LiCoO2 solution injected into half sealed cell • Heated in oven to: evaporate solvent, create porosity, form conductive adhesion • PGE separator solution injected on electrode • Heated in oven to create gel separator • Graphite anode solution injected onto copper current collector • Heated in oven to form desired properties • Final processing occurred in argon glove box environment • Electrolyte inserted followed by anode coated current collector • Epoxy applied to metal-to-glass junction Note: Battery above to left made with gap separator • No air leakage during test duration 5mm 4 mm 3mm 4 mmBattery MEMS Sensor