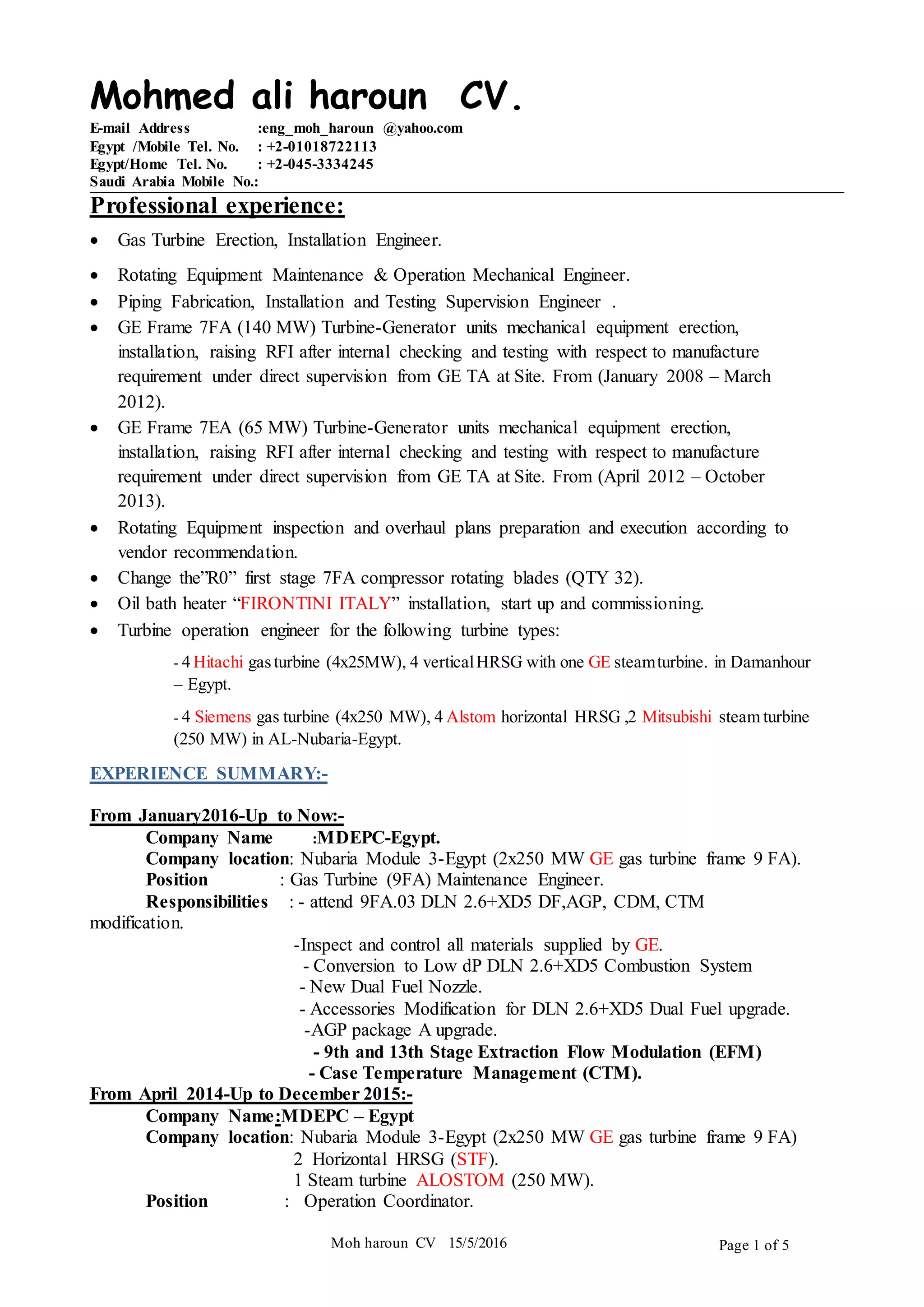

Mohmed Ali Haroun's resume provides details of his professional experience working on gas turbine projects in Egypt and Saudi Arabia over the past 15 years. He has experience in turbine installation, maintenance, and operation. His most recent role was as a gas turbine maintenance engineer in Egypt from 2016 to present.