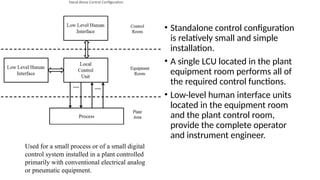

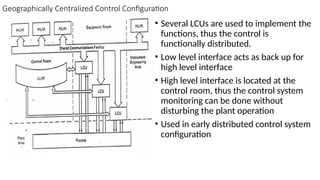

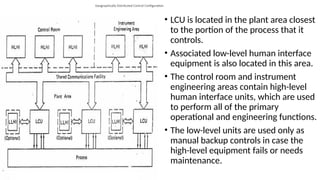

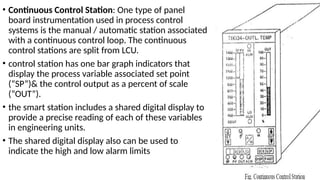

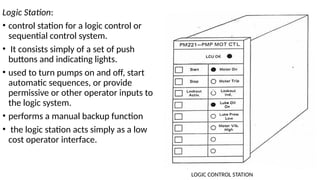

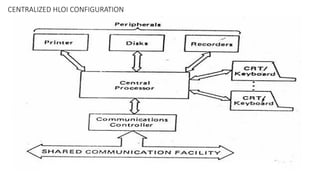

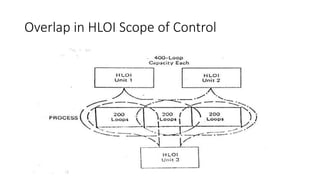

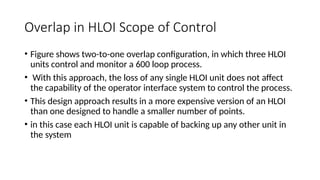

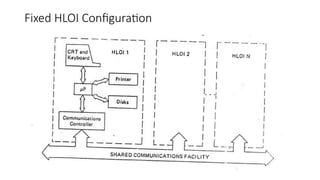

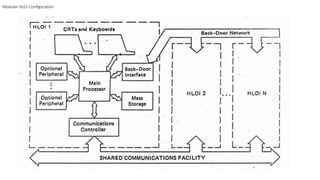

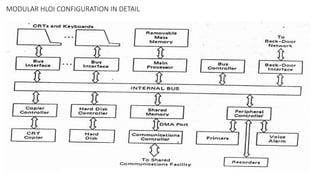

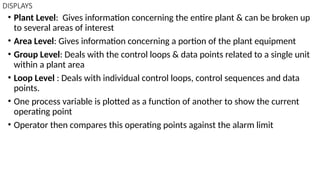

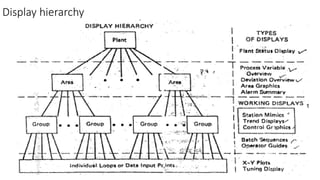

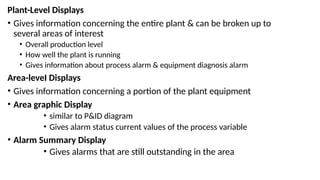

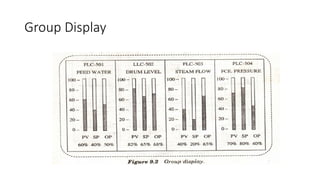

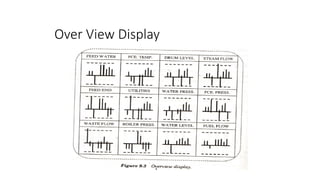

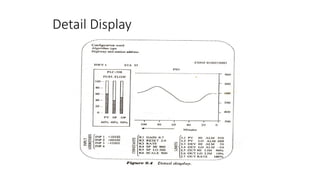

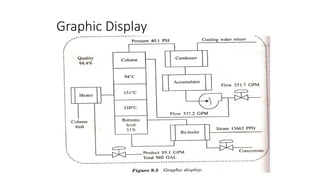

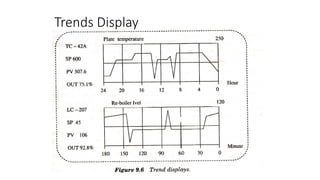

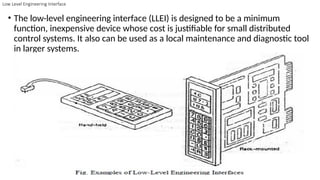

The document discusses various configurations and components of operator interfaces in automated control systems, highlighting their importance for safe and effective operation. It covers standalone, geographically centralized, and distributed control configurations, as well as low-level and high-level operator interfaces, detailing their functions, advantages, and applications. Additionally, it addresses the engineering interfaces required for configuring and diagnosing these systems, emphasizing the need for user-friendly interaction and flexibility in modern control environments.