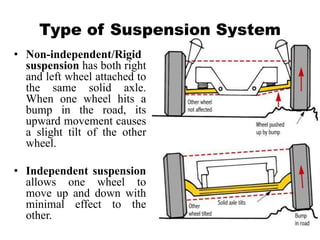

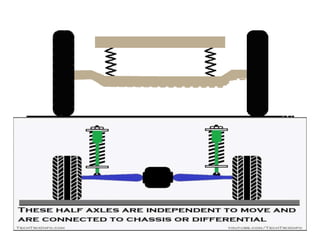

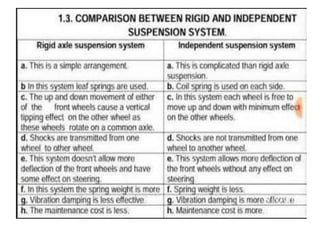

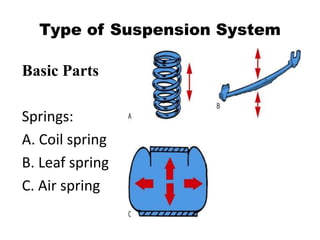

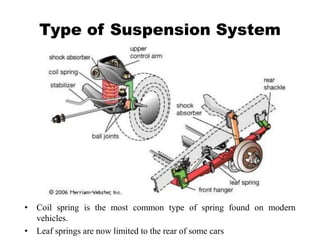

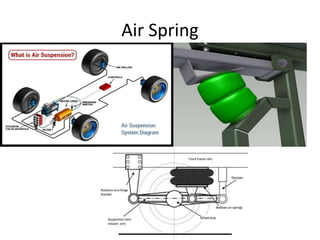

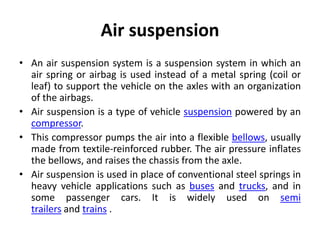

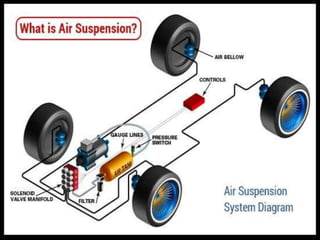

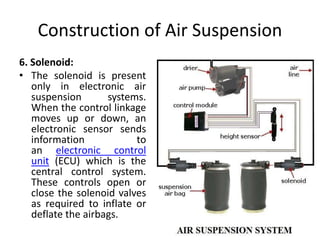

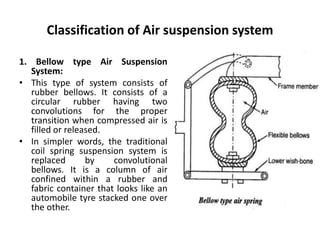

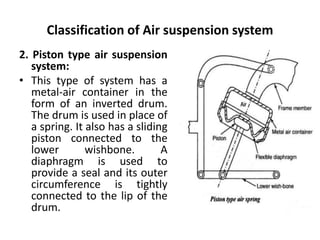

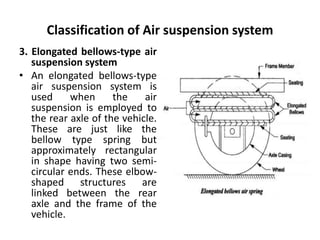

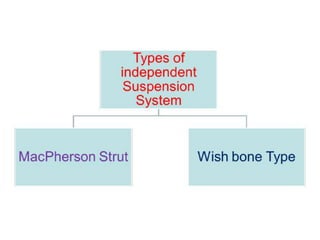

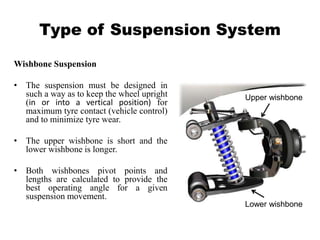

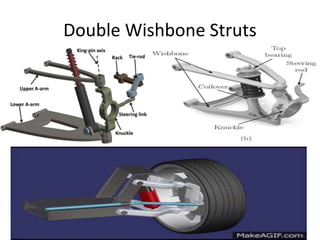

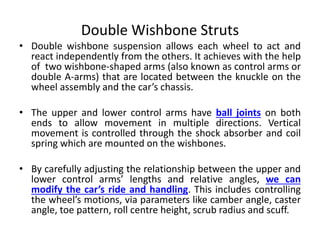

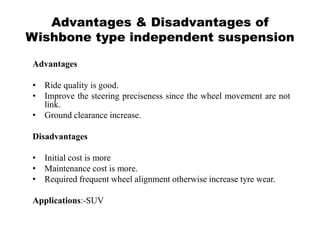

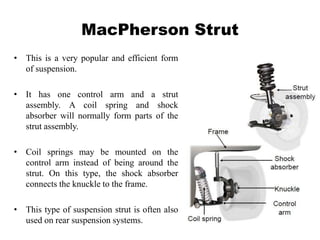

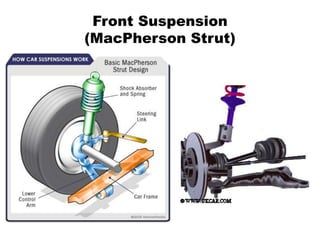

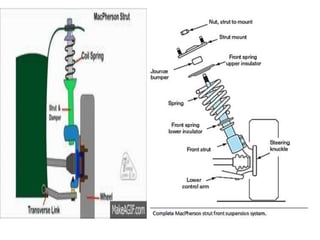

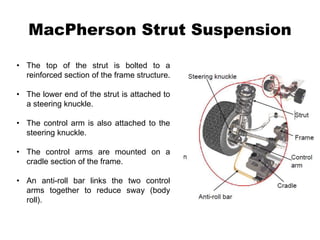

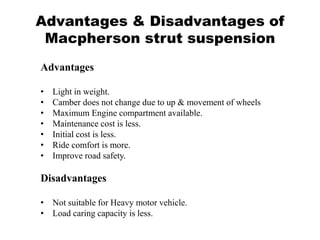

The document discusses different types of suspension systems used in vehicles. It describes non-independent suspension which connects both wheels to the same solid axle, causing one wheel's movement to affect the other. Independent suspension allows each wheel to move independently with minimal effect on the other. Common systems include MacPherson strut suspension which uses a strut and control arm, and double wishbone suspension which uses upper and lower control arms to connect each wheel to the frame. Air suspension replaces metal springs with air bags or bellows to provide a smooth, adjustable ride.