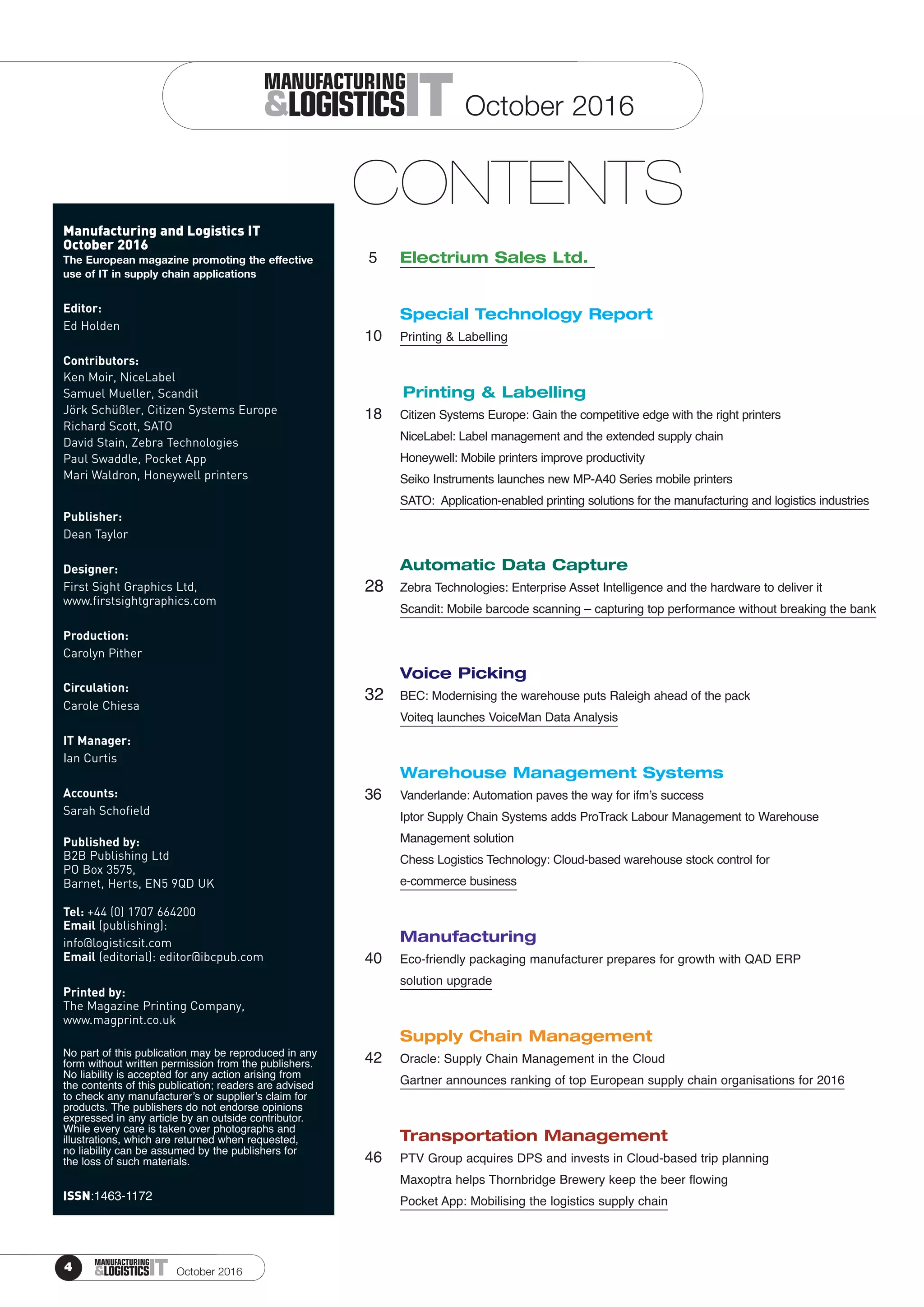

Electrium Sales Ltd. recently implemented DynaSys' Demand Planning software to improve its demand forecasting and sales and operations planning processes. Previously, Electrium relied on spreadsheets for these functions. The new system provides statistical analysis of historical demand data for each of Electrium's 14,000 SKUs. This allows more accurate demand forecasting and stock levels. Electrium also uses SAP for ERP, Phocas for data mining and analysis, and SAP WMS for warehouse management. These systems provide accurate inventory data, high stock levels, and improved operational efficiencies. Electrium aims to further optimize its IT systems using lean methodology.

![www.logisticsit.com

for example. NiceLabel works with a number of retailers on

supplier labelling. In the case of a leading luxury goods retailer,

our LMS was initially deployed within a number of regional

warehouses, then to several manufacturing sites and has now

just been rolled out across the business. The next stage of

development for the retailer is to deploy the solution within its

branded shops so that labels and tags can be reprinted in store

so products don’t have to be sent back to the warehouse, which

could result in lost sales opportunities.

Brand protection

Also, from a brand consistency and brand protection

perspective, the retailer is now able to control suppliers’

labelling activity and to be able to stop production overruns by

building-in anti-counterfeiting RFID methodology that can be

controlled via the web.

[subhead] Quality or regulatory compliance

Any company that relies on a quality management system to

remain ISO 9001 compliant should consider LMS as it provides

similar quality controls and procedures for the entire labelling

process. Highly regulated industries such as life sciences

(medical device manufacturers and pharmaceutical) require a

centralised, standardised labelling solution and it is critical in

order for these companies to remain compliant.

Regulatory requirements are very similar in both the medical

device and pharmaceutical sectors. In the US, for example, both

are regulated to 21 CFR Part 11, part of the Code of Federal

Regulations that establishes the US Food and Drug

Administration (FDA) regulations on electronic records and

electronic signatures (ERES). One of NiceLabel’s clients in this

area is pharmaceutical manufacturing company Krka, which

delivers medications to more than 70 countries worldwide. The

company has centralised and standardised its labelling

operations with NiceLabel’s LMS. The solution has improved

Krka’s master data management, streamlined compliance and

provided a next-generation system to support future growth.

Complete system

Labelling systems have moved away from being a ‘box’ to

becoming a complete business system offering greater agility

and empowering business users to streamline the whole

labelling process. It’s about not relying so much on IT; for

example, for making label change requests. We see this need

across all industries and among all sizes of company.

Companies want universal intelligent labels and the ability to

consolidate label variations. They also want to mitigate risk and

optimise processes by being able to seamlessly integrate with

the ERP’s or MES’s master data. NiceLabel is dedicated to

helping businesses to modernise and achieve significant

financial and productivity gains from their labelling process. We

call this ‘print productivity’.

Streamline your labeling

More than a million

companies use NiceLabel

technology to reduce

the complexity of

barcode labeling.

www.nicelabel.com

Find the solution that best meets your needs

Start producing professional labels without IT help.

Streamline label printing to control labour costs

and eliminate errors.

Standardize your entire labeling process to meet

quality requirements.](https://image.slidesharecdn.com/mlitoctober2016-161101104500/75/Mlit-october-2016-21-2048.jpg)

![P

urchasing barcode scanners has

become a matter of varied

choices. No longer are enterprises

restricted to selecting from an

array of dedicated scanners or

traditional mobile computers. Barcode

scanning options now include smartphones.

Organisations must determine which device

will deliver the scanning performance needed

at the right price.

As any IT buyer knows, one of the most

important considerations in a technology

purchase is getting the biggest bang for your

buck. Upfront costs are only one of many

factors barcode scanning device buyers need

to include in their evaluation. Others include

how long the device will last, how frequent

and expensive maintenance and repairs will

be, ruggedness, the amount of training

needed, ergonomics, scan performance

levels, and how many different tasks the

device will handle.

Taken together, these and other elements

comprise the total cost of ownership (TCO).

TCO accounts for all hard costs (such as the

device itself, the software that runs on it and

associated software development costs) and

soft costs (such as training, operation and

downtime expenses).

Lower TCO

First, it's important to understand that

smartphones can be deployed as

consumer-grade devices to be used in a

variety of enterprise workplaces. However,

they are also available in rugged models to

ensure operation in physically demanding

environments. By deploying ruggedised

smartphones, or smartphones protected by

rugged cases, enterprises can further lower

TCO and benefit from the same durability

as traditional rugged mobile computers or

dedicated scanners.

Mitigating the higher hardware costs of

rugged smartphones is the fact that they

still have a much lower TCO than the

dedicated scanning devices traditionally

used in demanding scan scenarios.[1]

Even

so, mobile computers can still cost over five

times as much as a rugged smartphone

over the device's lifetime. Meanwhile,

rugged smartphones developed by

traditional barcode scanning hardware

manufacturers can cost three times as

much as standard iOS or Android

smartphones.[2]

Fortunately, other options exist for

enterprises seeking to perform rugged

scanning operations without paying too high

a price. In good news for supply chain

managers seeking convenient and efficient

scanning solutions, enterprise technology

providers offer cloud-based software that

utilises the built-in camera and flash of a

smartphone to turn it into an enterprise

scanner. Many smartphone manufacturers

also offer ruggedised smartphones

designed for use in harsh environments.

Employee familiarity

Some organisations are even leveraging

employee's personal devices instead of

investing in enterprise hardware. Apps that

utilise a smartphone's camera can be extended

to personal devices via bring your own device

(BYOD) IT policies, eliminating hardware costs

from the TCO equation. Training on iOS and

Android-based smartphones may also be

easier and more cost-effective, simply because

of employee familiarity.

Other benefits, which may further reduce the

TCO of a consumer smartphone (ruggedised

or non-ruggedised), include its applicability to

numerous non-scanning functions. As

opposed to a dedicated scanning device,

smartphones can also be utilised for tasks

such as communication and navigation.

Rugged smartphones, as well as

smartphones protected by ruggedised cases,

offer a lower TCO by a large margin. IT

buyers and supply chain managers should

note they also offer alternative advantages to

businesses with a barcode scanning

requirement. With fully-ruggedised and

encasement options now available,

smartphone-based scanning solutions offer a

more economically viable alternative that will

suit the rigours of even the most demanding

environments.

AUTOMATIC DATA CAPTURE

MOBILE COMPUTING

30 ITMANUFACTURING

&LOGISTICS www.logisticsit.com

Data Capture

Mobile barcode scanning – capturing top

performance without breaking the bank

October 2016

By Samuel Mueller, CEO, Scandit.

[1]

TCO Models for Mobile Computing and Communications Platforms – VDC Research

[2]

Total Cost of Ownership of Mobile Barcode Scanning – Scandit

Mitigating the higher hardware costs of rugged smartphones is the

fact that they still have a much lower TCO than the dedicated scanning

devices traditionally used in demanding scan scenarios.”

“](https://image.slidesharecdn.com/mlitoctober2016-161101104500/75/Mlit-october-2016-30-2048.jpg)