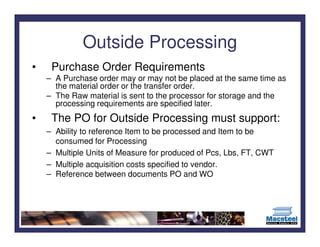

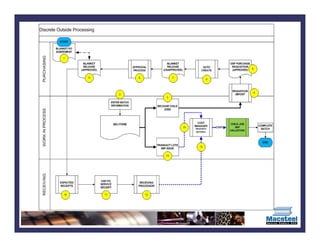

Macsteel Service Centers USA outsources some of its manufacturing to processing vendors. It needs its IT system to support outsourced manufacturing by tracking purchase orders, material costs, inventory, and processing details for outsourced jobs. The system must allow referencing raw materials and finished goods, capturing multiple costs, and providing full visibility of outsourced production statuses and balances. It also requires flexibility to handle multiple items, conversions, transfers between vendors, and adding product item numbers.