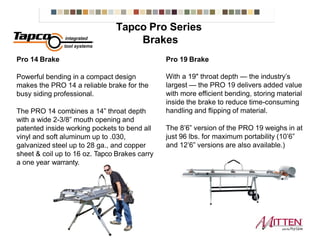

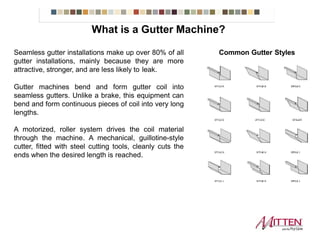

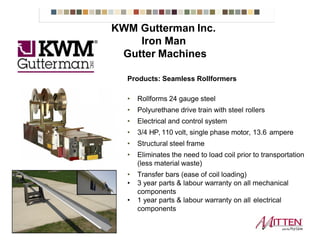

This document outlines a product knowledge course focused on bending equipment used in the construction industry, covering the different types of brakes and gutter machines available through Mitten. It details the features, selection criteria, and common applications for this equipment, emphasizing the importance of precision in achieving quality craftsmanship. Additionally, it provides insights into various manufacturers, including Tapco, Van Mark, Alum-A-Pole, New Tech Machinery, and KWM Gutterman, along with their specific products and offerings.